Kusukela ngo-2012 - i-Smart Weight izibophezele ekusizeni amakhasimende ukwandisa umkhiqizo ngezindleko eziphansi.

Isimiso Sokusebenza Komshini Wokupakisha we-VFFS

Enye yemishini ebaluleke kakhulu emigqeni yesimanje yokupakisha umshini wokuvala oqondile. Usiza izinkampani zokupakisha izinto ngokushesha, ngokuphephile nangokulinganayo kungakhathaliseki ukuthi ukudla okulula, okungewona ukudla kanye nophuphu.

Kulo mhlahlandlela, sizobheka ukusebenza komshini, ukugeleza kokukhiqiza kanye nezinyathelo zokuqapha ezidingekayo ngaphansi kwezinhlobo ezahlukene zemikhiqizo. Uzokwazi futhi izisekelo zokulungisa nokuhlanza ukuze uqinisekise ukuthi uhlelo luhlala lusebenza kahle futhi lusebenza kahle. Qhubeka ufunda ukuze ufunde kabanzi.

Isimiso Sokusebenza Somshini Wokupakisha we-VFFS

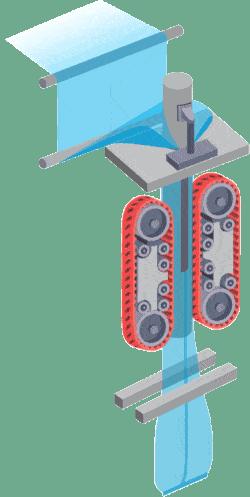

Umshini wokugcwalisa ifomu eliqondile nokuvala udala iphakheji ephelele kusuka ku-roll yefilimu bese uyigcwalisa ngenani elifanele lomkhiqizo. Konke kwenzeka ohlelweni olulodwa oluqondile, okwenza umshini usheshe, ube mncane, futhi ufaneleke ezimbonini ezahlukene.

Umjikelezo wokusebenza uqala ngokudonswa kwefilimu emshinini. Ifilimu igoqwe ngepayipi elibumbayo bese lenza isimo sesikhwama. Ngemva kokwakha isikhwama, umshini ube usuvala phansi, ugcwalise umkhiqizo bese uvala phezulu. Inqubo iphindaphindwa ngokuphindaphindiwe ngesivinini esikhulu.

Izinzwa zisiza ukugcina ukunemba ekuqondeni ifilimu kanye nobude besikhwama. Izikali ze-multihead noma izigcwalisi ze-auger ziyimishini yokukala noma yokulinganisa esetshenziswa nomshini wokupakisha we-VFFS ukuqinisekisa ukuthi iphakethe ngalinye linenani elifanele lomkhiqizo. Ngenxa yokwenza okuzenzakalelayo, abakhiqizi bathola ikhwalithi yephakheji ehambisanayo futhi kudingeka umsebenzi omncane.

Ukugeleza Kwenqubo Yokukhiqiza

Inqubo yokukhiqiza emshinini wokupakisha we-VFFS ilandela ukulandelana okucacile nokuvumelanisiwe. Nakuba imishini ihlukahluka ngomklamo, izinhlelo eziningi zisebenzisa ukugeleza okufanayo okuyisisekelo:

● Ukondla Ifilimu: Umqulu wefilimu yokupakisha ufakwa emshinini. Amarola adonsa ifilimu kahle ukuze avimbele imibimbi.

● Ukwakheka Kwefilimu: Ifilimu igoqa ipayipi lokwakheka bese ithatha isimo njengesikhwama esime mpo.

● Ukuvala Okuqondile: Ibha efudumele idala umthungo oqondile owakha umzimba wesikhwama.

● Ukuvala Ngezansi: Imihlathi yokuvala evundlile ivala ukuze kudaleke phansi kwesikhwama.

● Ukugcwalisa Umkhiqizo: Uhlelo lokulinganisa lufaka inani eliqondile lomkhiqizo esikhwameni esisanda kwakhiwa.

● Ukuvala Okuphezulu: Imihlathi ivala ingxenye ephezulu yesikhwama bese iphakethe liqedwa.

● Ukusika Nokukhipha Igesi: Umshini usika izikhwama ezilodwa bese uzihambisa esigabeni esilandelayo somugqa wokukhiqiza.

Lokhu kugeleza kugcina umkhiqizo uzinzile futhi kusiza ukugcina amazinga aphezulu okukhipha. Umphumela uba uvalwe kahle, amaphakheji afanayo alungele ukubhokisa noma ukuphathwa okwengeziwe.

Izinyathelo Zokuqapha Zokupakisha Izinhlobo Ezihlukene Zemikhiqizo

Umshini wokupakisha we-VFFS ungasetshenziswa ezimbonini ezahlukahlukene kodwa ukunaka okukhethekile kuhlobo ngalunye lomkhiqizo kufanele kukhokhwe ukuqinisekisa ikhwalithi nokuphepha. Nazi izinyathelo ezibalulekile zokuqapha:

◆ Imikhiqizo Yokudla

Ukupakishwa kokudla kufanele kwenziwe ngaphansi kwezimo ezihlanzekile nezilawulwayo. Khumbula la maphuzu:

● Faka amafilimu asezingeni lokudla kanye nezingxenye zomshini wokuhlanza.

● Izinga lokushisa lokuvala kufanele ligcinwe ukuze kugwenywe ukuvuza.

● Indawo yokulinganisa kufanele igcinwe ihlanzekile ukuze kuvinjelwe ukungcola.

● Qiniseka ukuthi umkhiqizo awubhajwe esikhwameni.

Abakhiqizi bokudla basebenzisa futhi izinsimbi zokuhlola insimbi noma bahlole izikali ngomshini wabo wokupakisha we-VFFS ukuze bathuthukise ukuphepha nokunemba.

◆ Impuphu

Ezinye izimpushana zinothuli futhi zingathinta izimbobo.

Izinyathelo ezibalulekile zifaka:

● Sebenzisa izinhlelo zokulawula uthuli kanye nezindawo zokugcwalisa ezivalekile.

● Khetha uhlelo lokugcwalisa olufanele, njengesithasiselo sokugcwalisa i-auger lapho ugcwalisa impuphu.

● Ukuthambekela ekucindezelweni kokuvala kusiza ekuqinisekiseni ukuthi azikho izimpushana ezifakwe emithungweni.

● Gcina umswakama uphansi ukuze ugweme ukuqhekeka.

Lezi zinyathelo ezilandelayo ziwusizo ekugcineni izivalo zihlanzekile futhi zigcwele kahle.

◆ Imithi kanye namakhemikhali

Lena imikhiqizo okumele ilandelwe ngokuqinile imigomo yayo yokuphepha. Abakhiqizi kufanele:

● Gcina indawo ezungezile idosi ihlanzekile futhi ihlanzekile.

● Sebenzisa ifilimu elwa nokungaguquguquki uma kudingeka.

● Qinisekisa ukuthi umthamo unembile ukuze kuhlangatshezwane nezimfuneko zomthetho.

● Vimbela insalela yamakhemikhali ukuthi ingathintani nezinsimbi zokuvala.

Umshini wokuvala oqondile osetshenziswa kulo mkhakha uvame ukufaka izinzwa, ukuvikela okwengeziwe, kanye nezici zokuhlanza ezithuthukisiwe.

◆ Izinto Ezingezona Ukudla

Imikhiqizo engeyona ukudla efana nehadiwe, izingxenye ezincane, kanye nezingxenye zepulasitiki ingaba nemiphetho ebukhali noma izimo ezingalingani.

Izinyathelo zokuphepha zifaka:

● Ukukhetha ifilimu ejiyile noma eqinisiwe.

● Ukuqinisekisa ukuthi umkhiqizo awulimazi imihlathi yokuvala.

● Ukulungisa ubude besikhwama kanye nesimo saso ukuze silingane kangcono.

● Ukusebenzisa izivalo eziqinile ezintweni ezisindayo.

Lezi zinyathelo zisiza ekuvikeleni kokubili umkhiqizo kanye nomshini.

Izidingo Zokunakekela Nokuhlanza

Ukugcinwa komshini wokupakisha we-VFFS kuwugcina usebenza futhi kwandisa isikhathi sawo sokuphila. Uhlelo lubhekana nefilimu, umkhiqizo, ukushisa kanye nokunyakaza komshini ngakho-ke ukuhlolwa njalo kubalulekile.

Nazi imisebenzi eyinhloko:

● Ukuhlanza Kwansuku Zonke: Susa izinsalela zomkhiqizo, ikakhulukazi eduze kwendawo yokugcwalisa kanye nepayipi lokwakha. Ngemikhiqizo enothuli, hlanza njalo imigoqo yokuvala.

● Hlola Izingxenye Zokuvala: Hlola imihlathi yokuvala ukuthi ayigugi yini. Izingxenye ezigugile zingabangela izivalo ezibuthakathaka noma ifilimu eshisiwe.

● Hlola Ama-Roller kanye Nomzila Wefilimu: Qiniseka ukuthi ama-roller adonsa ifilimu ngokulinganayo. Ama-roller angaqondile kahle angabangela ukugoba noma ukudabuka kwefilimu.

● Ukugcoba: Faka ukugcoba ezingxenyeni ezihambayo njengoba kuhlelwe ngumenzi. Ukugcoba ngokweqile ezindaweni zokuvala kufanele kugwenywe.

● Izingxenye Zikagesi: Hlola izinzwa nezinto zokushisa. Ukwehluleka kulezi zindawo kungabangela ukulandelela ifilimu okungekuhle noma izivalo ezibuthakathaka.

● Ukulinganisa Uhlelo Lokulinganisa: Ukuhlolwa kwezinhlelo zokulinganisa noma zomthamo kufanele kwenziwe njalo ukuze kugcwaliswe kahle. Lokhu kuyiqiniso ikakhulukazi ngezimpushana nemithi.

Lezi zinyathelo ziwusizo ekuqinisekiseni ukusebenza njalo kwanoma yimuphi umshini wokugcwalisa ifomu nokuvala oqonde phezulu.

Imicabango Yokugcina

Umshini wokupakisha we-VFFS uyisisombululo esisebenza ngezindlela eziningi futhi esinokwethenjelwa ezimbonini eziningi. Ufaneleka kakhulu ezinkampanini ezidinga isivinini, ukunemba kanye nokusebenza okunokwethenjelwa uma kukhulunywa ngokwenza amaphakheji, ukuwagcwalisa, nokuwavala ngokunyakaza okukodwa. Kungakhathaliseki ukuthi ukudla, impuphu, imithi noma imikhiqizo engeyona ukudla, ukwazi isimiso sokusebenza somshini kuzokusiza ukuthi ube nomugqa wokukhiqiza ophumelelayo.

Uma uzimisele ukuthuthukisa inqubo yakho yokupakisha, cabanga ngalo lonke uhlu lwezinhlelo ezizenzakalelayo ezinikezwa yi I-Smart Weight . Izixazululo zethu ezintsha zizokuvumela ukuthi usebenze ngokukhiqizayo nasezingeni eliphezulu. Xhumana nathi manje ukuze uthole okwengeziwe noma ucele ukwesekwa komuntu siqu komugqa wakho wokukhiqiza.

I-Smart Weight ingumholi womhlaba wonke ezinhlelweni zokupakisha ezinesisindo esinembile kakhulu nezihlanganisiwe, ethenjwa amakhasimende angaphezu kwe-1,000 kanye nemigqa yokupakisha engaphezu kwe-2,000 emhlabeni jikelele. Ngokusekelwa kwendawo e- Indonesia, eYurophu, e-USA nase-UAE , sinikeza izixazululo zomugqa wokupakisha we-turnkey kusukela ekuphakeleni kuya ekufakeni ama-pallet.

Isixhumanisi Esisheshayo

Umshini Wokupakisha