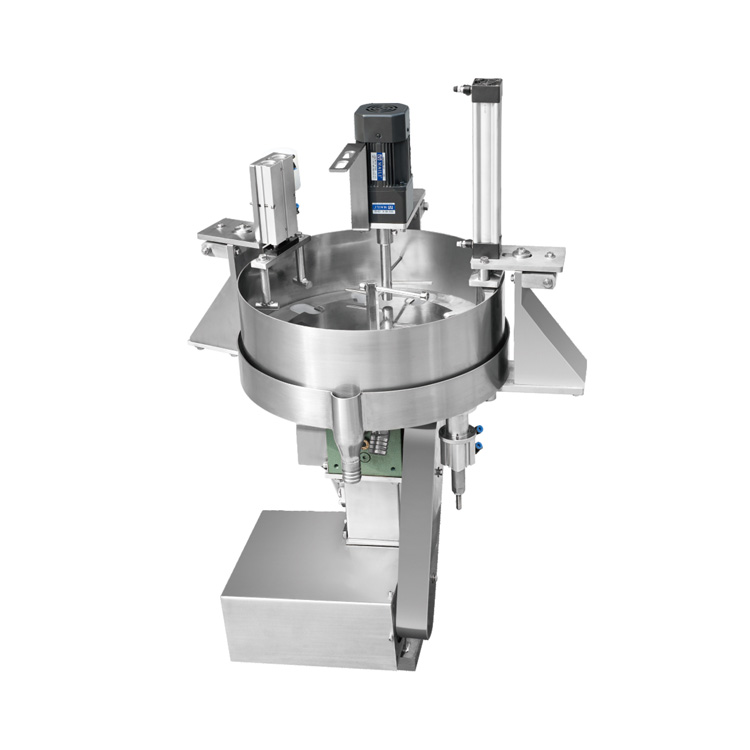

Izinto zokuqala kuqala, ake sihlukanise ukuthi yini aumshini wokugcwalisa inkomishi ye-volumetric imayelana. Lesi sigcwalisi senkomishi ye-volumetric simayelana nokulinganisa inani elifanele lemikhiqizo okufanele lifakwe ezitsheni. Ilungele imbudumbudu encane nempushana ngoba ikala ngevolumu esikhundleni sesisindo, iqinisekisa ukuthi isiqukathi ngasinye sithola inani elifanele lanoma yini oyithelayo.

Cabanga ukugcwalisa inkomishi ngelayisi: uma ugcwalisa ngokugcwele ngendlela efanayo isikhathi ngasinye, isisindo sihlala sivumelana. Kanjalo aumshini wokugcwalisa i-volumetric isebenza.

Inezinkomishi eziningi ku-hopper yokugcina, ngayinye iqoqa futhi ikala inani eliqondile lomkhiqizo.

Njengoba umshini usebenza, imikhiqizo yakho egelezayo yamahhala iwela ezinkomishini, futhi njengoba izungeza iye phezulu komjikelezo, umshini uleveli kokuqukethwe ukuqinisekisa ukuthi inkomishi ngayinye igcwaliswa ngevolumu efanayo ncamashi. Le nqubo iyisihluthulelo sokugcina ukungaguquguquki - njengalapho ugcwalisa inkomishi yakho yerayisi kuze kube sekupheleni njalo.

Uma izinkomishi sezigcwalisiwe futhi zilinganisiwe, zifinyelela endaweni yokukhipha. Lapha, umshini wokugcwalisa i-volumetric ukhulula okuqukethwe ezitsheni ezilindile, izikhwama, noma amayunithi okupakisha ngezansi. Lo mjikelezo uphinda ngokushesha, okuvumela ukugcwaliswa kwesivinini esikhulu ngaphandle kokudela ukunemba noma ukungaguquguquki kwevolumu yomkhiqizo.

Umlingani ophezulu womshini wokugcwalisa i-volumetric ungumshini wokugcwalisa ifomu mpo, i-duo eguquguqukayo embonini yokupakisha. Le nhlanganisela ithuthukisa ukusebenza kahle kanye nobubanzi bemisebenzi yokupakisha, inikeza isixazululo esiphelele kusukela ekugcwalisweni kuya ekupakishweni kwemikhiqizo eyomile egelezayo yamahhala.

Umshini wokugcwalisa ifomu mpo uhambisana ne-i-volumetric cup filler ngokuthatha umkhiqizo okalwe ngokunembile bese uwupakisha ngaphandle komthungo. Nansi indlela abasebenza ngayo ndawonye:

Inqubo yokupakisha edidiyelwe: Ngemuva kokuthi umshini wokugcwalisa inkomishi ye-volumetric ulinganise futhi ukhiphe umkhiqizo, umshini wokugcwalisa ifomu ome mpo uyathatha. Yakha izikhwama noma izikhwama ezivela emigqeni yefilimu eyisicaba, igcwalise ngomkhiqizo, bese iwavala. Le nqubo eyenziwe lula ukusuka ekugcwaliseni kuye ekupakisheni iyasebenza futhi yonga isikhathi.

Okuhle ngempela ngalesi simiso wukuguquguquka kwalo. Ungalungisa ivolumu yezinkomishi ukuze ihambisane nemikhiqizo ehlukene noma osayizi bokupakisha. Lokhu kusho ukuthi umshini ofanayo ungasetshenziswa emikhiqizweni eyahlukene, ngokumane ulungise izilungiselelo. Kuyisixazululo esilingana konke esilungele izimboni lapho ukuhlukahluka komkhiqizo kuyinto evamile.

Ngaphezu kwalokho, ukwakheka komshini kuvame ukufaka izici ezifana ne-agitator ku-hopper. Lesi siphehlisi sigcina umkhiqizo ungami futhi ungahlangani, uqinisekisa ukugeleza okushelelayo ezinkomishini kanye nevolumu engashintshi njalo. Yile mininingwane ecatshangelwayo eyenza ukugcwalisa inkomishi ye-volumetric hhayi nje umshini, kodwa ingxenye ethembekile yomugqa wokukhiqiza.

Empeleni, umshini wokugcwalisa inkomishi ye-volumetric umayelana nokunemba, ukusebenza kahle, nokuvumelana nezimo. Kungakhathaliseki ukuthi upakisha ukudla, imithi, noma izimpahla zasembonini, iqinisekisa ukuthi umkhiqizo ngamunye ugcwaliswa ngenani eliqondile elidingekayo, ngokushesha nangokungaguquguquki. Umqondo olula - ofana nokugcwalisa inkomishi yerayisi - kodwa wenziwe ngendlela eguqula ukusebenza kahle kwemigqa yokukhiqiza kuzo zonke izimboni ezihlukahlukene.

Ukuhlukahluka komshini wokugcwalisa i-volumetric kuyinhlanganisela enkulu. Ungakwazi ukulungisa osayizi benkomishi yemikhiqizo ehlukene, okwenza kube yisixazululo esivumelana nezimo ezimbonini ezihlukahlukene.

Enye yezinzuzo ezivelele ze-aumshini wokugcwalisa inkomishi ye-volumetric ihlanganisa iphaneli yokulawula esebenziseka kalula eyenzelwe ukusetshenziswa kalula, kanye nezilawuli zomoya ezinciphisa isidingo sokuthi opharetha baphathe umkhiqizo ngesikhathi sokugcwalisa. Ngaphezu kwalokho, imishini eminingi iza ifakwe izinsiza zokulungisa ezakhelwe ngaphakathi, iqinisekisa ukuphumula okuncane nokusebenza okungaguquguquki, okushelelayo.

I-synergy phakathi kokugcwalisa inkomishi ye-volumetric kanye nomshini wokugcwalisa ifomu mpo kukhulisa kakhulu isivinini nokunemba enqubweni yokupakisha, okwenza le nhlanganisela ibe namandla ekusebenzeni kahle kokukhiqiza.

Ngokuhlanganisa izinqubo zokugcwalisa nokupakisha, lokhu kubhanqa kunciphisa isidingo semishini eyengeziwe kanye nomsebenzi, kunikeza isixazululo esihlukile somnotho samabhizinisi.

Inhlanganisela iqinisekisa ikhwalithi engaguquki kukho kokubili umthamo womkhiqizo ogcwalisiwe kanye nobuqotho bokupakishwa, ukugcina amazinga aphezulu kuwo wonke umugqa wokukhiqiza.

Le nhlanganisela isebenza kahle endaweni, njengoba umshini wokugcwalisa ifomu ome mpo uqondanisa ngokuqondile inqubo yokupakisha, igcina indawo ebalulekile yaphansi ezindaweni zokukhiqiza.

Ngamafuphi, umshini wokugcwalisa inkomishi ye-volumetric umayelana nokunemba nokusebenza kahle, ulungele ukupakisha imikhiqizo eminingi ngokuqhubekayo nangokushesha.

Uma ufuna omunye wale mishini yokugcwalisa i-volumetric, cabanga ngalokhu:

* Okugcwalisayo (usayizi nokuthungwa).

* Kushesha kangakanani futhi kungakanani okudingayo ukugcwalisa.

* Izosebenza kanjani ngokusetha kwakho kwamanje.

* Kulula kangakanani ukunakekela nokuhlanza.

Ngaphandle komshini wokugcwalisa inkomishi ye-volumetric, umhlaba wemishini yokupakisha unikeza izinhlobonhlobo zemishini yokugcwalisa, ngayinye yakhelwe ukuhlangabezana nezidingo nezinselelo ezithile kulayini wokukhiqiza. Ukuqonda lezi zindlela ezihlukile kungasiza amabhizinisi ukuthi akhethe okokusebenza okufanele ngezidingo zawo ezihlukile.

Kumabhizinisi agxile ekwandiseni umugqa wawo wokukhiqiza, umshini wokukala ama-multihead uwukukhetha okuvelele. Iphumelela kakhulu ekukaleni, ukugcwalisa imikhiqizo ngesivinini nangokunemba, ngenxa yomsebenzi wayo oguquguqukayo wokugeleza kwamandla adonsela phansi kanye nenketho yokwengeza imibhobho ehlukene yemikhiqizo ehlukahlukene. Izici ezibalulekile okufanele uzibheke zihlanganisa isilinganiso sokugcwalisa esilungisekayo, iphaneli yokulawula esebenziseka kalula, idizayini ehlangene, ukwakhiwa okuhlala isikhathi eside, kanye nokuthengeka. Lo mshini awulona nje ithuluzi kodwa uwutshalomali ekuthuthukiseni ukusebenza kahle kokukhiqiza kwakho.

Umshini wokugcwalisa i-powder uyithuluzi elibalulekile lokuphatha izinto eziyimpuphu. Ngokuvamile iqukethe i-hopper ehambisa impushana ibe yisitsha ngeshubhu. Lo mshini uklanyelwe ukukhipha inani elifanele lempushana ngokungaguquki, okuwenza ube yisisekelo ezimbonini ezifana nokudla, imithi, namakhemikhali. Ikhono layo lokugcwalisa uhla lwamasayizi weziqukathi ngokunembe nangokushesha, kuhambisana nokusebenza kwayo okuqondile nokugcinwa kokunakekelwa okuphansi, kuyenza ibe yimpahla ebalulekile.

Lolu hlobo lomshini, kufaka phakathi imodeli yepompo ye-peristaltic ethandwayo, ilungele ukugcwalisa imikhiqizo ye-viscous efana namasoso nama-lotions. Iphampu yokufuduka enhle inikeza ukulawula okunembile phezu kokugeleza komkhiqizo, iqinisekisa ukunemba nokuthembeka ekugcwaliseni. Le mishini ibiza kancane kunezinye izinhlobo futhi isetshenziswa kakhulu ekukhiqizeni ukudla neziphuzo, ekukhiqizeni ukunakekelwa komuntu siqu, kanye nokukhiqizwa kwemithi yokugcwalisa uhla lwemikhiqizo emabhodleleni, ezitsheni, kumashubhu, noma kumaphakethe amabhamuza.

Umshini wokugcwalisa i-capsule, owusizo ikakhulukazi ezimbonini zemithi kanye nemikhiqizo yezempilo, uklanyelwe ukugcwalisa amaphilisi namaphilisi angenalutho. Iwumshini ozenzakalelayo ngokuphelele osebenzisa ubuchwepheshe be-PLC obuthuthukisiwe ukuze usebenze ngendlela elula, ephumelelayo. Ukuguquguquka kwayo kuvumela ukugcwalisa osayizi abahlukahlukene bama-capsule nezinhlobo, okuyenza ibe ithuluzi elinezici eziningi lamabhizinisi amancane kuya kwaphakathi nendawo, izimboni zemikhiqizo yokunakekelwa kwempilo, kanye nabakhiqizi bemithi yamakhambi baseShayina.

Ngayinye yale mishini yokugcwalisa iletha izinzuzo eziyingqayizivele etafuleni, ihlinzeka ngezici ezihlukahlukene zenqubo yokupakisha. Ukusuka ekuphatheni izinto eziyimpuphu kuye ekugcwaliseni uketshezi lwe-viscous, le mishini ithuthukisa ukusebenza kahle, ukunemba kanye nokukhiqiza ezindaweni ezahlukahlukene zezimboni. Ukuqonda amakhono abo kuvumela amabhizinisi ukuthi enze izinqumo ezinolwazi lapho enweba noma ethuthukisa imishini yawo yokupakisha.

Ekusongeni, umshini wokugcwalisa inkomishi ye-volumetric ugqama njengehhashi langempela embonini yokupakisha nokukhiqiza. Ukunemba kwayo ekukaleni nasekukhipheni imikhiqizo, ikakhulukazi ama-granules amancane nezimpushana, kuguqula indlela amabhizinisi abheka ngayo ukupakisha. Uma ufuna umshini wekhwalithi ozosiza ukuthuthukisa umkhiqizo wakho, i-Smart Weigh yinkampani enedumela elihle nethembekile, enikezela ngomshini wokugcwalisa inkomishi wevolumu ephezulu onawo!

XHUMANA NATHI

Isakhiwo B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Sikwenza Kanjani Ukuhlangana Futhi Sichaze Umhlaba jikelele

Imishini Yokupakisha Ehlobene

Xhumana nathi, singakunikeza izixazululo ze-turnkey zokupakisha ukudla

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | Wonke Amalungelo Agodliwe