Horizontal VS Rotary Packaging Machine: How to Choose the Right One?

Efficient packaging plays a crucial role in modern industries, ensuring that products reach customers in excellent condition while optimizing operational efficiency. Packaging machines are indispensable for businesses aiming to achieve consistency, speed, and quality in their packaging processes. Among the many packaging solutions available, horizontal and rotary packaging machines stand out as popular options. Each offers unique capabilities suited to specific applications. This article aims to help businesses understand these machines and make an informed choice based on their needs.

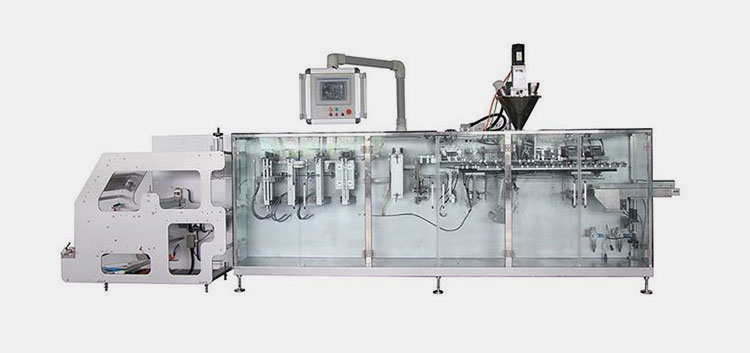

What are Horizontal Packaging Machines

A Horizontal Packaging Machine is an automated machine that packs products into pouches, bags, or other containers. It also named horizontal form fill seal machine. It forms, fills, and seals in a horizontal layout. These machines are used in the food, pharma, cosmetics, and chemicals industries as they are efficient and precise and can pack various products like liquids, solids, and powders.

The machine works by feeding products onto a conveyor, where they are measured, filled, and sealed using adjustable parts. This ensures airtight and uniform packaging that extends the product life while maintaining quality and hygiene.

▶Features:

1. Automated: Most models are fully automatic, with no manual intervention required.

2. Pouch Formation: Can make various pouch types, flat, stand-up, and resealable, as per product requirement.

3. Sealing Technology: Ultrasonic, heat, or impulse sealing for airtight and secure closure.

4. Filling Systems: Adjustable parts for accurate filling of various products, consistency and less wastage.

5. Compact: Many models have small footprints and are suitable for small spaces.

6. Material Compatibility: Can handle various packaging materials, from polyethylene to biodegradable films.

7. User Friendly Interface: Touchscreen and electronic display for easy operation and troubleshooting.

▶Advantages

● Cost-Effective for Specific Applications: Ideal for small-scale production or lightweight items where precise packaging is essential.

● High Precision: Ensures accurate filling and sealing, minimizing material waste and enhancing product presentation.

▶Limitations

● Limited Pouch Sizes: These machines are not ideal for packaging larger pouches or products requiring heavy-duty materials.

● Larger Footprint: Requires more space than rotary packing machines, which can be a drawback for businesses with limited facility size.

What are Rotary Packaging Machines?

A Rotary Packaging Machine is an automated system designed to simplify the packaging process for various products, from food and pharmaceuticals to chemicals and cosmetics. These machines are known for their rotary design, which can perform multiple packaging steps in a circular motion to maximize efficiency and accuracy. Prefabricated plastic bags are used, and the machine is a heat sealer to ensure secure and airtight closure. Unlike horizontal systems, rotary machines handle premade pouches, making them a popular choice for packaging powders, liquids, and granules.

Rotary packaging machines replace the manual packaging process, making them valuable for big companies and small to medium enterprises. They can achieve more packaging automation with minimal labor.

▶Features of Rotary Packing Machines

1. Automation: Eliminates manual labor by automating the process, reduces errors and increases productivity.

2. Easy to Use: User-friendly interface requires minimal technical knowledge to operate.

3. Compatible: Can handle various preformed pouches, plastic, paper and aluminum foil.

4. Multi-Function: Can do bag feeding, opening, filling, sealing and output in one cycle.

5. Customizable: Adjustable settings for different bag sizes, filling volume, and sealing parameters.

6. High Speed: Handling hundreds of bags per hour saves production time.

7. Space Saving: Compact design saves space in industrial areas.

▶Advantages

● High-Speed Production: Capable of producing a large volume of packaged products in a short time, making it suitable for large-scale operations.

● Versatility: Can handle a variety of packaging formats and materials, including premade pouches of different sizes and shapes.

▶Limitations

▲ Speed: Rotary packing machines are generally slower than horizontal form-fill-seal (HFFS) machines, making HFFS more suitable for high-speed (80-100 packs/min) production.

Key Differences Between Horizontal and Rotary Packing Machines

When selecting the ideal packaging machine for your business, understanding the key differences between horizontal and rotary packaging machines is crucial. Each machine type offers unique advantages depending on your production needs, packaging style, and budget.

✔Speed:

◇Horizontal packaging machines typically offer higher speeds, making them suitable for high-volume production environments. The continuous, linear movement of the packaging process allows these machines to maintain a consistent and faster throughput. This can be especially beneficial when dealing with a large number of units to be packed within a limited timeframe.

◇ Rotary packaging machines, on the other hand, usually operate at a slightly slower pace due to their rotational mechanism. While they are still capable of high speeds, the movement of the machine relies on the rotation of containers or pouches, which can introduce slight delays compared to the continuous, linear operation of horizontal systems. However, rotary machines can still be highly efficient for many applications, especially where smaller batch runs or precise filling are more important.

✔Filling Volume:

◇ Horizontal machines typically handle smaller filling volumes. This is because they work with a single chamber or limited-volume system in which the product is dispensed directly into the pouch from the filling station. While horizontal systems are great for high-speed operations, they might face limitations when dealing with larger quantities of product per pouch or container.

◇ Rotary machines, on the other hand, are better equipped to handle larger filling volumes. They often use multiple filling stations within the rotary head, allowing them to fill larger pouches or containers more efficiently. The multi-station design is particularly advantageous for high-volume products or when multiple pouches need to be filled simultaneously.

✔Pouch Type:

Both horizontal and rotary pouch packing machines can produce similar pouch types, but the method of producing the pouch differs significantly.

○ Horizontal machines are typically responsible for creating pouches directly from a roll of film. This gives them the flexibility to produce custom-shaped pouches and adjust the size of each pouch to meet specific product requirements. The film is fed into the machine, formed into a pouch, filled with product, and then sealed—all in a continuous motion. This process allows for a higher level of customization in pouch design, especially when dealing with varied or unique product shapes.

○ Rotary machines, in contrast, are designed to handle pre-formed pouches. The pouches are supplied to the machine already formed, which simplifies the overall operation. These machines focus on filling and sealing the pre-formed pouches. While the pouch types available may be more standardized, this method can still be highly efficient, particularly for products that need consistent, quick packaging without custom requirements.

✔Price:

○ Horizontal packaging machines tend to be more expensive due to their complex design and higher production capabilities. These machines often feature advanced mechanisms, multiple stations for filling, and the ability to form and seal pouches from raw film. Their flexibility, speed, and customization capabilities all contribute to a higher initial investment.

○ Rotary machines are typically more affordable, as they are simpler in design and rely on handling pre-formed pouches. The lack of a need for pouch formation reduces the cost of materials and machinery. While rotary machines may not offer the same level of flexibility as horizontal machines, they provide a solid solution for businesses looking for a lower-cost alternative that still offers efficient performance, especially when pre-formed pouches are suitable for the product.

✔Repair & Maintenance:

□ Horizontal machines tend to require more frequent repairs and maintenance due to their complexity and higher number of moving parts. These machines often operate at high speeds, which can lead to wear and tear over time, particularly on components like motors, conveyors, and sealing systems. Routine maintenance is necessary to keep the machine running smoothly, and downtime for repairs can become costly if not managed effectively. The higher complexity of horizontal systems also means that technicians may need more specialized training to handle any issues that arise.

□ Rotary machines, with their simpler design and fewer moving parts, generally experience lower maintenance requirements. Since these machines primarily focus on filling and sealing pre-formed pouches, they are less prone to the mechanical strain seen in more complex systems. Additionally, the lack of pouch-forming processes and fewer high-speed components means that rotary machines are less likely to experience breakdowns. As a result, these machines tend to have a longer operational lifespan with less frequent maintenance needs, making them a more cost-effective choice in the long run for businesses that require lower maintenance overhead.

In summary, the Rotary type is better than the Horizontal type. Most customers choose the rotary type. Rotary pouch packing machines have more than 80% market share. But in some cases, you can also choose the Horizontal type. For example, the Horizontal will be higher speed if you need a small dose.

Factors to Consider When Choosing the Right Machine

Selecting the right packaging machine is a critical decision for any business aiming to optimize operations and maintain product quality. Below are key factors to consider when deciding between horizontal and rotary packing machines:

● Type of Product: The nature of the product—solid, liquid, granular, or irregularly shaped—significantly impacts the choice of machine. Horizontal machines excel in packaging smaller and lightweight products, while rotary machines handle a wider variety.

● Production Volume: Rotary machines are more suitable for high-volume production environments, while horizontal machines are used in small—to medium-scale operations.

● Packaging Format: Consider the desired packaging format, such as pre-made pouches. Rotary machines offer greater flexibility for complex designs, whereas horizontal machines specialize in simpler formats.

● Budget and ROI: Businesses should evaluate the initial investment, operational costs, and long-term value of the machine. Horizontal form fill seal machines may have higher upfront costs but provide better returns with small pouches for large-scale operations.

● Space Availability: Ensure your facility has adequate space for the chosen machine. Rotary machines are better suited for compact areas, while horizontal machines require longer room.

● Maintenance and Technical Support: Choose a machine that offers easy maintenance and readily available technical support. This ensures minimal downtime and consistent performance.

Why Choose a Smart Weigh Pack Solution?

Smart Weigh Pack stands out as a trusted leader in the weighing and packaging industry, offering innovative solutions tailored to many industries. It was established in 2012. Smart Weigh has over a decade of expertise and combines cutting-edge technology with a deep understanding of market needs to deliver high-speed, accurate, and reliable machines.

Our comprehensive product range includes multihead weighers, vertical packaging systems, and complete turnkey solutions for food and non-food industries. Our skilled R&D team and 20+ global support engineers ensure seamless integration into your production line, catering to your unique business needs.

Smart Weigh's commitment to quality and cost-efficiency has earned us partnerships in over 50 countries, proving our ability to meet global standards. Choose Smart Weigh Pack for innovative designs, unmatched reliability, and 24/7 support that empower your business to increase productivity while reducing operational costs.

Conclusion

Choosing between horizontal and rotary packaging machines depends on various factors, including product type, production volume, budget, and space availability. While horizontal machines offer precision and cost-effectiveness for specific applications, rotary machines excel in price and versatility, catering to high-volume industries.

Carefully assessing your business needs ensures you select the most suitable machine. Smart Weigh Pack stands ready to assist with expert guidance and advanced automation packaging system solutions. Contact Smart Weigh today to discover the perfect packaging machine for your operations.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine