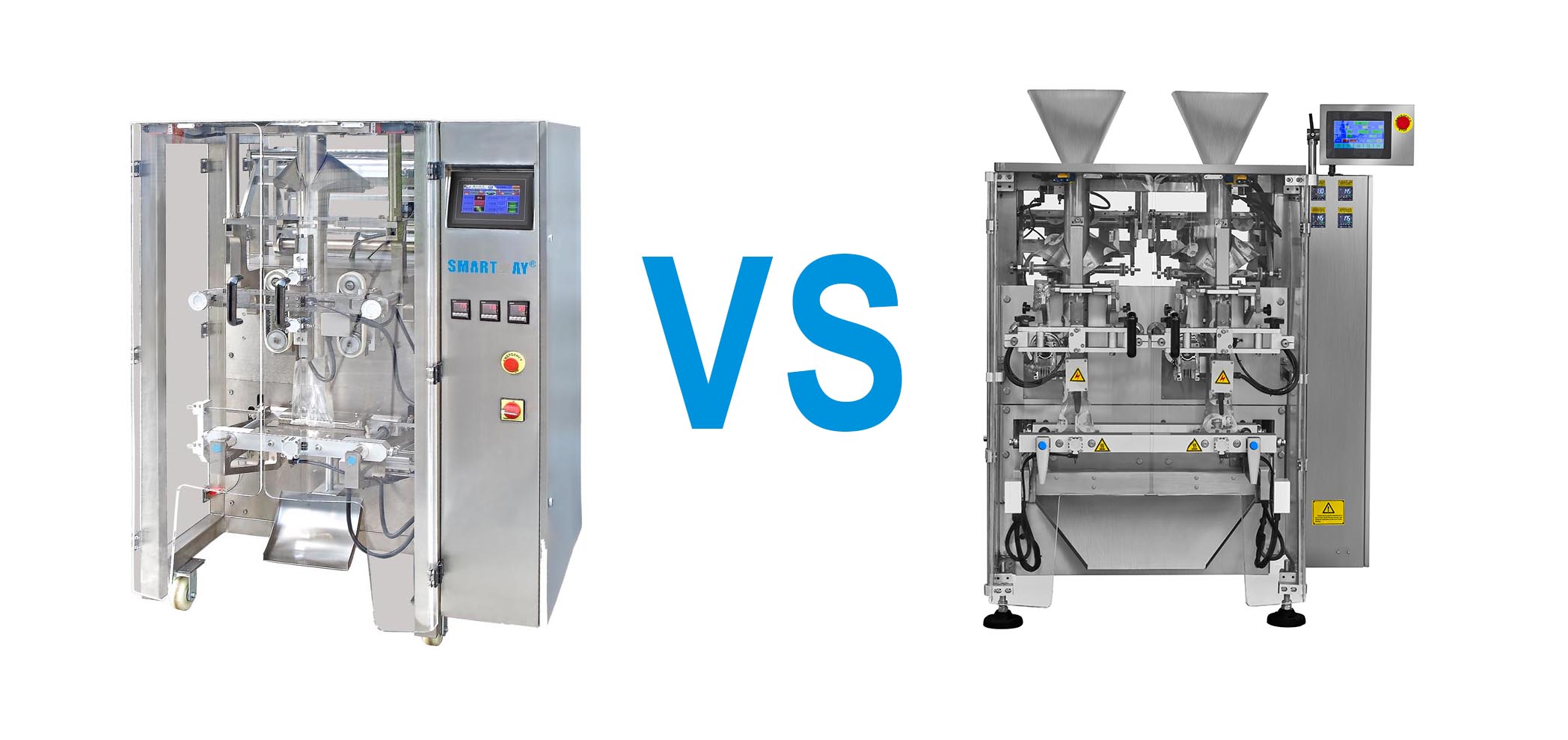

High-Speed VFFS Packing Machine Comparison

What Makes VFFS Selection Essential for Production?

If you choose the wrong VFFS machine, you could lose more than $50,000 in productivity per year. There are three primary types of systems: 2-servo single lane, 4-servo single lane, and dual lane. Knowing what each one can do will help you choose the ideal one for your packaging needs.

Today's packaging needs more than just speed. Food makers need equipment that works well with a wide range of goods and keeps quality high. The most important thing is to make sure that the machines you use can meet your specific production needs, product attributes, and operational goals.

What Are Your VFFS Machine Options?

2-Servo Single Lane: Reliable Performance (70-80 bags/minute)

The 2-servo VFFS delivers consistent 70-80 bags per minute performance with proven reliability. Two servo motors control film pullling and sealing operations, providing precise bag formation while maintaining straightforward operation and maintenance.

This configuration works well for operations producing 33,600-38,400 bags per 8-hour shift. The system excels with standard products like coffee, nuts, and snacks where consistent quality matters more than maximum speed. Simple operation makes it ideal for facilities prioritizing reliable performance and easy maintenance.

4-Servo Single Lane: Precision Engineering (80-120 bags/minute)

The 4-servo VFFS provides 80-120 bags per minute through advanced servo control of film tracking, jaw movement, and sealing operations. Four independent motors deliver superior precision and adaptability across varying products and conditions.

This system produces 38,400-57,600 bags per 8-hour shift while maintaining exceptional quality consistency. The additional servos enable precise adjustments for different products, reducing waste and improving seal integrity compared to simpler systems.

Dual Lane VFFS: Maximum Productivity (130-150 bags/minute total)

Dual lane systems operate 65-75 bags per minute per lane, achieving combined output of 130-150 bags per minute. This configuration doubles productivity while requiring minimal additional floor space compared to single lane systems.

The combined throughput produces 62,400-72,000 bags per 8-hour shift, making it essential for high-volume operations. Each lane operates independently, providing flexibility to run different products or maintain production if one lane requires maintenance.

Space efficiency becomes crucial in constrained facilities. Dual lane systems typically occupy 50% more floor space while delivering 80-90% higher productivity, maximizing output per square foot. This efficiency makes them attractive for urban facilities or expanding operations.

How Do These Systems Compare in Real-World Performance?

Speed and Capacity Differences

Production capacity varies significantly between configurations. The 2-servo system's steady 70-80 bags per minute suits operations with consistent demand around 35,000-40,000 bags daily. The 4-servo system's 80-120 bag range accommodates facilities needing 40,000-60,000 bags with quality precision.

Dual lane systems serve high-volume operations exceeding 65,000 bags daily. The 130-150 bag per minute capability addresses demand that single lane systems cannot meet efficiently, particularly in markets requiring rapid response to consumer demand.

Real-world performance depends on product characteristics and operational factors. Free-flowing products like coffee beans typically achieve upper speed ranges, while sticky or delicate items may require reduced speeds for quality maintenance. Environmental conditions also influence achievable speeds.

Quality and Flexibility Factors

Seal quality consistency improves with increased servo control. The 2-servo system provides reliable sealing for most applications with acceptable variation. The 4-servo configuration delivers superior consistency through precise pressure and timing control, reducing rejects and improving shelf life performance.

Product flexibility increases with servo sophistication. Simple 2-servo systems handle standard products effectively but may struggle with challenging applications. The 4-servo system manages varied products, film types, and bag formats while maintaining high speeds and quality standards.

Changeover efficiency affects daily productivity significantly. Basic product changes require 15-30 minutes across all systems, but format changes benefit from 4-servo precision through automated adjustments. Dual lane systems require coordinated changeovers but maintain 50% productivity during single-lane adjustments.

Which System Delivers the Best Results for Your Specific Needs?

When 2-Servo Systems Excel

Operations producing 35,000-45,000 bags daily with consistent products benefit from 2-servo reliability. These systems work well for established snack foods, coffee packaging, and dried products where proven performance outweighs cutting-edge features.

Single-shift operations or facilities with experienced operators appreciate the straightforward maintenance and operation. The lower complexity reduces training requirements while providing dependable results that meet most packaging quality standards.

Cost-conscious operations value the 2-servo system's balance of capability and investment. When maximum speed isn't required, this configuration delivers reliable performance without over-engineering for applications that don't demand advanced features.

4-Servo System Advantages

Operations requiring 45,000-65,000 bags daily with demanding quality standards benefit from 4-servo precision. These systems excel when consistent high-speed performance must be maintained across varying products and conditions.

Premium product lines justify 4-servo investment through superior presentation quality and reduced waste. The precision control maintains performance with challenging films and delicate products that would suffer in simpler systems.

Future-proofing considerations make 4-servo systems attractive for growing operations. As product lines expand and quality requirements increase, the platform provides advanced capabilities without requiring complete system replacement.

Dual Lane System Applications

High-volume operations exceeding 70,000 bags daily require dual lane capacity. These systems become essential when single lanes cannot provide adequate throughput, particularly for major brands with consistent high demand.

Labor efficiency improvements justify investment in premium cost environments. One operator managing 130-150 bags per minute provides exceptional productivity compared to operating multiple single lane systems requiring additional staff.

Production continuity needs favor dual lane redundancy. Critical operations where downtime creates significant costs benefit from continued operation during maintenance or unexpected issues affecting individual lanes.

How Do These Systems Integrate with Your Complete Production Line?

Upstream Equipment Requirements

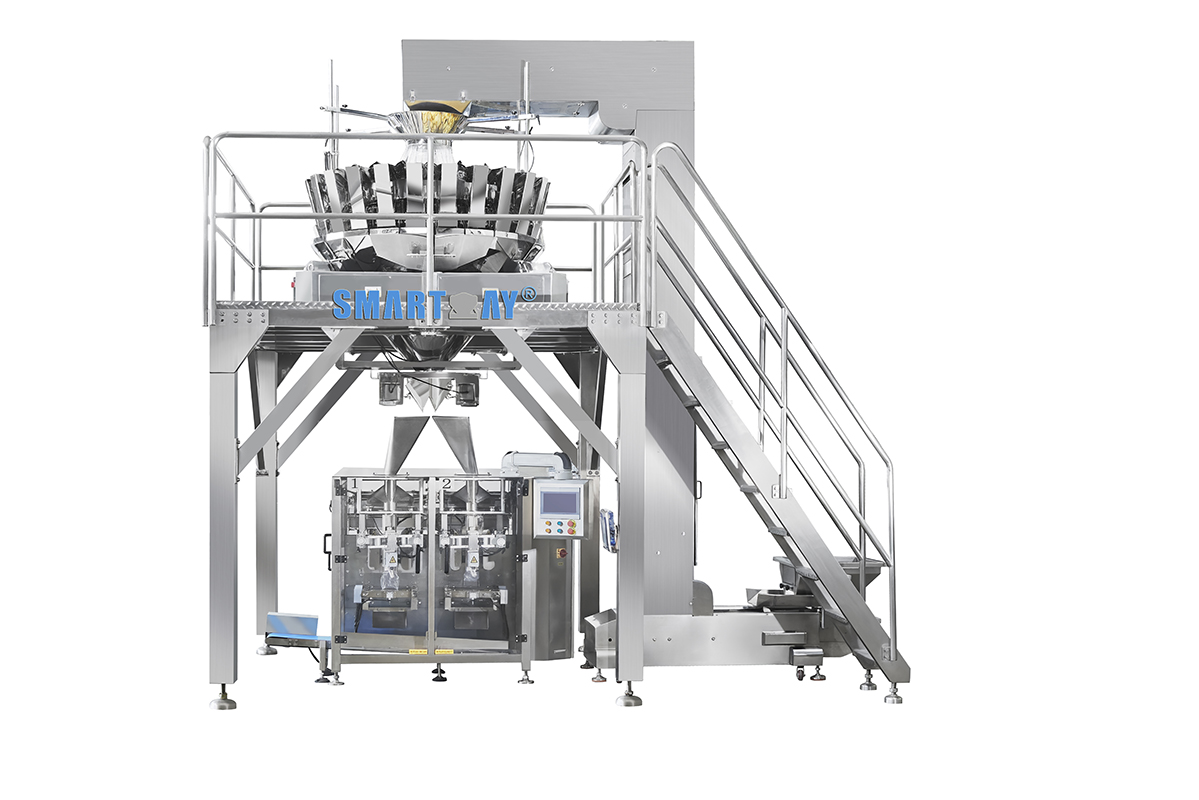

Multihead weigher selection varies by system type. The 2-servo systems pair well with 10-14 head weighers providing adequate product flow. The 4-servo systems benefit from 14-16 head weighers to maximize speed potential. Dual lane systems require twin weighers or single high-capacity units with proper distribution.

Conveyor capacity must match system output to prevent bottlenecks. Single lane systems need standard conveyors with surge capacity, while dual lane systems require enhanced conveying or dual feed arrangements to handle the higher product flow effectively.

Downstream Considerations

Case packing requirements scale with output levels. Single lane systems work with traditional case packers at 15-25 cases per minute. Dual lane systems producing 130-150 bags per minute need high-speed equipment capable of 30+ cases per minute.

Quality control integration remains important across all configurations. Metal detection and checkweighing systems must match line speeds without becoming limiting factors. Dual lane systems may require individual inspection for each lane or sophisticated combined systems.

What Should Guide Your Final Investment Decision?

Volume-Based Guidelines

Daily production requirements provide clear selection guidance. Operations under 45,000 bags typically benefit from 2-servo reliability. Production between 45,000-65,000 bags often justifies 4-servo investment for enhanced capability. Volumes exceeding 70,000 bags usually require dual lane capacity.

Growth planning influences long-term value. Conservative estimates suggest selecting systems with 20-30% excess capacity to accommodate expansion without immediate replacement. The 4-servo platform often provides better scalability than upgrading from 2-servo systems.95

Quality and Flexibility Needs

Product complexity affects system requirements significantly. Standard free-flowing products work well with any configuration, while challenging products benefit from 4-servo precision. Operations running multiple product types favor advanced systems for changeover efficiency.

Quality standards influence selection criteria. Basic packaging requirements suit 2-servo systems, while premium products often justify 4-servo investment for consistent presentation. Critical applications may require dual lane redundancy for continuity assurance.

Operational Considerations

Facility constraints impact system selection. Space-limited operations favor dual lane efficiency for maximum productivity per square foot. Maintenance capabilities affect complexity tolerance—facilities with limited technical support benefit from simpler 2-servo systems.

Labor availability influences automation level selection. Operations with skilled technicians can maximize 4-servo or dual lane advantages, while facilities with basic operator training may prefer 2-servo simplicity for consistent results.

How Can You Maximize Your VFFS Investment Returns?

Smart Weigh's engineering expertise ensures optimal performance across all configurations. Our servo technology delivers consistent performance whether you select 70 bags per minute reliability or 150 bags per minute dual lane productivity. Complete integration with weighers, conveyors, and quality systems creates seamless operation.

Performance guarantees back our speed and quality commitments with comprehensive service support. Technical consultation helps match system capabilities to your specific requirements, ensuring optimal return on investment while positioning your operation for future growth and success.

The right VFFS system transforms your packaging operation from cost center to competitive advantage. Understanding the capabilities and applications of each configuration helps you select equipment that meets current needs while supporting long-term business objectives through reliable, efficient packaging automation.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine