How To Use Corn Flour Packing Machine

Do you find it difficult to evenly pack corn flour without spilling? A corn flour packing machine can make this process quicker, cleaner, and much more accurate! Many manufacturers have trouble with things like packing flour by hand, uneven weights in bags at the best of times, leaking powder, and labor prices.

Automatic packing machines can remedy all these situations in a methodical and fast way. In this guide, you will find out what a corn flour packaging machine is, how it operates, as well as exactly how to correctly operate it step by step.

You will also find very useful maintenance hints and troubleshooting tips, as well as good reasons why Smart Weigh is one of the best-known names producing flour packaging equipment.

Understanding Corn Flour Packing Machines

A corn flour packing machine is built to fill and seal bags of fine powders such as corn flour, wheat flour, or similar kinds of products with consistency and accuracy. As corn flour is a light and dusty substance, the maize flour packaging machine fills the bags with an auger system for filling that gives a reliable measurement each time without overflows and without air pockets.

These machines can be set for all bag types, such as pillow, gusseted bags, or pre-made bags. Depending on your production capabilities, you can have a semi-automatic or a completely automatic system. The latter can weigh, fill, be sealed, printed, and even counted in a continuous operation.

The result is a neat and professional type of packaging which preserves freshness and keeps wastage down to a minimum. Whether you are a corn flour mill in a small way or on a large scale, an automatic corn flour packing machine improves production efficiency and brings a smoother production line.

Key Components and Functions

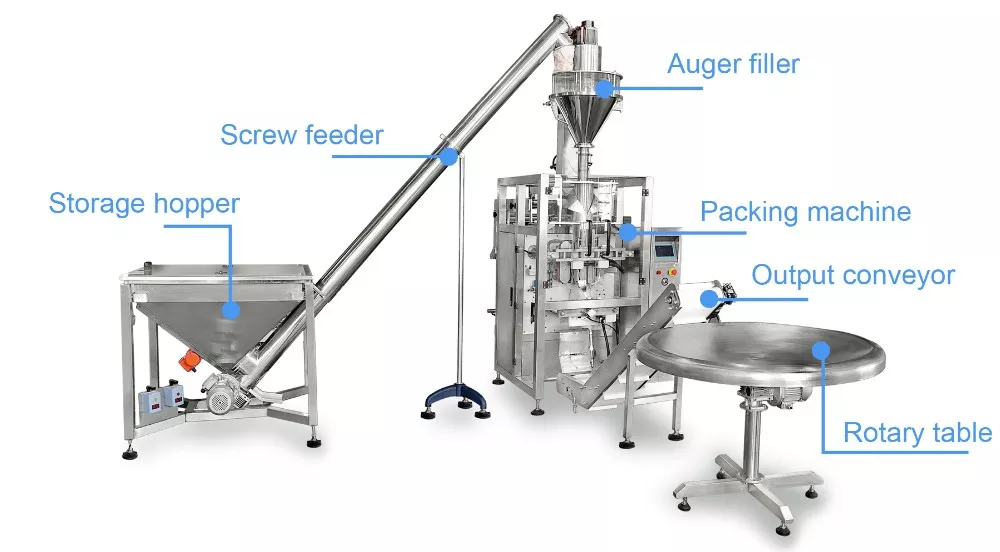

A corn flour packing machine consists of multiple main components working together to supply an efficient packaging function.

1. Infeed Hopper with screw feeder: Holds the bulk of corn flour before entering the filling mechanism.

2. Auger Filler: The main mechanism to accurately weigh and dispense the proper amount of flour into each package.

3. Bag Former: Forms the package from the roll film during flour filling.

4. Sealing Devices: Closures of heat or pressure to properly close and maintain the freshness of the package.

5. Control Panel: Where all weights, baggie length, and filling speed can be preset.

6. Dust Collection System: A collection system that removes the fine powder from the sealing and work area during packaging.

These components together furnish the corn flour packaging machine with an efficient, accurate, and safe food operation.

Step-by-Step Operating Procedure

Using a maize flour packaging machine is an easy task when the following procedure is followed.

▶Step 1: Prepare the Machine

Be sure all components are thoroughly clean of the remaining powder. Apply power to the machine. Be sure the hopper is full of fresh corn flour.

▶Step 2: Set the Variables

Enter the through the touch screen panel the desired weight per bag, sealing temperature, and the packing speed desired.

▶Step 3: Load the Package Material

In the roll-food type packing machine, the film is wound onto the reel, and the forming collar is set. In the pre-pouch type packer, the empty pouches are placed in the magazine.

▶Step 4: Start the Filling Process

The automated auger filler weighs and fills each bag.

▶Step 5: Seal & Print

After filling, the machine seals the bag with heat and prints the batch code or date if needed.

▶Step 6: Quality Inspection and Collection

Inspect the sealed bags to make sure there are no leaks or weight problems, then move them to the conveyor for labeling or boxing.

This simple process results in professional and consistent packaging every time.

Maintenance and Cleaning Methods

Proper maintenance will keep your corn flour packing machine running smoothly for years. Here are a few simple steps:

● Daily Cleaning: Wipe the auger, hopper, and sealing area between production runs to eliminate any accumulation.

● Check for Leaks: Be certain there are no loose fittings or leaking seals that could cause flour to escape.

● Lubrication of Moving Parts: Periodically lubricate the food-grade lubricant on the chains, gears, and mechanical joints.

● Inspection of Sensors: Clean and test the weight sensors and sealing sensors frequently to ensure proper performance.

● Calibration: Recheck the weighing system periodically for accuracy of filling.

● Avoid Moistness: Keep the machine dry to avoid the flour clumping effect and electric failure.

Following this maintenance schedule will not only extend the life of the machine but will also afford the user regular packaging quality and hygiene, both of which are appropriate for any food-producing plant.

Common Problems and Troubleshooting

It often occurs that a corn flour packaging machine gives a little trouble through slightly defective technique, all due to modern invention, but here are a few of the methods of repairing the various troubles that may arise in the daily run:

● Improper filling weight: Assure yourself that the auger or weight sensor is accurately adjusted, and that there is no accumulation of dust product about which would cause inaccuracy.

● Bad seal quality: Check the heat of the seal to see that it is not too low, or that the Teflon belts do not need replacing. No product must be allowed to lodge itself about the seal.

● Film or pouch not feeding to the machine properly: The feeding roll may require realignment, or the tension adjustment may be faulty.

● Dust escapes from the machine: Be sure the hatch of the hopper is well shut and check to see that the seals are good.

● Errors on display control: Restart control and check connections.

Most of the conditions mentioned above are sufficiently grave that it is easy to get a remedy when the cause is discovered. Every machine should be regularly treated to cleaning and treated, besides properly adjustment of its setup, and a general preventive maintenance scheme, which is meant to be used to lessen breakdowns and secure maximum efficiency in production.

Why Choose Smart Weigh Flour Packing Solutions

High-efficiency maize flour packaging machines are those that are represented among the products in the Smart Weigh installation, all of which are specially designed for the powder product line. An auger filling installation gives the accuracy that is required where packing weight is concerned, and there is no dust dispersion at all.

There are machines being made for VFFS roll film packing installation, and also machines being made that are suitable for preformed pouch line installations that fit a lot of production conditions. Machines by Smart Weigh are known for a smart controlling arrangement, a stainless steel construction, good access for cleaning, and, in fact, comply with the international tests for slaughtering, hygiene, and safety.

Smart Weigh solutions will include features such as automatic labeling, coding, metal detection, checking weighing, etc., which means that they have the perfect solution right through for the complete automation from one end to the other. Whether you need a small setup or a full production line, Smart Weigh provides reliable machines, quick installation, and lifetime technical support, helping you save time, reduce waste, and deliver high-quality flour packaging every time.

Conclusion

Using a corn flour packing machine is the best way to make your packaging faster, cleaner, and more consistent. It reduces manual work, prevents powder waste, and ensures accurate weight in every bag. With regular maintenance and proper use, this machine can greatly improve your production efficiency.

Choosing a trusted brand like Smart Weigh guarantees high-quality equipment, dependable service, and long-lasting performance. Whether you're a small producer or a large manufacturer, Smart Weigh has the right packaging solution for your flour business.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine