Top 5 Duplex VFFS Machine for High-Speed Packaging

Is your packaging line the main bottleneck holding back your company's growth? This delay limits your output and costs you sales. A dual VFFS machine can effectively double your capacity in nearly the same footprint.

A dual VFFS, or twin-tube, machine makes two bags at once, maximizing throughput. Key manufacturers include Viking Masek, Rovema, Velteko, Kawashima, and Smart Weigh. Each offers unique strengths in speed, precision, flexibility, or cost-effective stability.

Choosing the right machine is a huge decision for any production manager. Over the years, I've seen factories completely transform their output just by picking the right partner and the right technology. It's about more than just speed; it's about reliability, flexibility, and the footprint on your factory floor. Let's start by looking at the top names in the industry before diving into what makes each of them a strong contender.

Who are the Top Dual VFFS Manufacturers?

Sorting through different machinery suppliers is tough. You're worried about making a costly mistake. Here are the leading brands you should know, making your choice much clearer and safer.

Top dual VFFS manufacturers known for high-speed reliability include Viking Masek, Rovema, Velteko, Kawashima, and Smart Weigh. They offer unique strengths in continuous motion speed, German precision, modular design, or proven cost-effective stability, providing solutions for diverse packaging needs.

When production managers look for a dual VFFS machine, a few names consistently come up. These companies have built strong reputations for performance, innovation, and reliability in different areas of the market. Some focus on achieving the absolute highest speeds, while others are known for their robust engineering or flexible designs. Understanding the key strengths of each manufacturer is the first step in finding the right fit for your specific production line, product, and budget. Below is a quick overview of the leading players we will explore in more detail.

Top Dual VFFS Machine Brands at a Glance

| Brand | Key Feature | Best For |

|---|---|---|

| 1. Viking Masek | Continuous Motion Speed | Maximum throughput (up to 540 bpm) |

| 2. Rovema | German Engineering & Compact Design | Reliability in limited floor space |

| 3. Velteko | European Modularity & Flexibility | Businesses with diverse product lines |

| 4. Kawashima | Japanese Precision & Reliability | High-volume lines where uptime is critical |

| 5. Smart Weigh | Cost-Effective Stability | 24/7 production with a low total cost of ownership |

1. What Makes the Viking Masek Twin Velocity a High-Speed Choice?

Ever wonder how some companies manage to pack over 500 bags per minute? The secret is often in continuous motion technology. Viking Masek offers a powerful solution designed for exactly this kind of throughput.

The Viking Masek Twin Velocity is a true dual-lane continuous motion VFFS machine. It forms and seals two bags at the same time. Its servo-driven jaws ensure consistent seals at very high speeds, reaching up to 540 bags per minute.

When we talk about high-speed packaging, the conversation often turns to continuous motion. Intermittent machines have to stop briefly for each seal, which limits their top speed. The Twin Velocity, however, uses a continuous motion design. This means the film never stops moving, allowing for much faster production. The key to its performance is its advanced servo-driven sealing jaws. These servos provide precise control over pressure, temperature, and timing. This ensures every single bag has a perfect, reliable seal, even at top speed. This level of consistency is critical for reducing waste and ensuring product quality. For businesses packaging high volumes of snacks, coffee, or powders, this machine is built to eliminate bottlenecks.

2. How Does the Rovema BVC 165 Twin Tube Maximize Output?

Are you running out of floor space in your factory? You need to increase production, but you can't expand your facility. A compact, high-output machine is often the best solution for this common problem.

The Rovema BVC 165 Twin Tube is known for its compact design and premium German engineering. It has two forming tubes in a small frame and features independent film tracking for each lane. This machine can pack up to 500 bags per minute reliably.

Rovema has a reputation for building robust, high-quality machines. The BVC 165 Twin Tube is a great example of this. Its main advantage is combining high speed with a compact footprint, making it perfect for factories where every square foot counts. One of its standout features is independent film tracking for each of the two lanes. This means you can make small adjustments to one side without stopping the other. This significantly reduces downtime and keeps production running smoothly. It's a small detail that makes a big difference in Overall Equipment Effectiveness (OEE). The machine also has excellent accessibility for cleaning and maintenance, which operators really appreciate.

3. How Does Velteko's Duplex Series Offer Unmatched Flexibility?

Does your product line change frequently? Your current machine is too rigid, causing long changeover times. This inflexibility costs you time and opportunities in a fast-moving market. A modular machine adapts with you.

Velteko's Duplex series uses European modular engineering to provide excellent flexibility. This design allows for quick changes between different bag formats and product types, making it ideal for companies with diverse or frequently updated product lines.

The core strength of Velteko's approach is modularity. In a modern factory, especially for contract packagers or brands with a huge product mix, the ability to adapt is crucial. A modular machine is built from interchangeable components. This means you can quickly swap out forming tubes to create different bag widths or change the sealing jaws for different film types. For a business that needs to switch from packing granola in pillow bags one day to packing candy in gusseted bags the next, this flexibility is a huge advantage. It dramatically reduces changeover time compared to a more fixed-purpose machine. This European engineering focus allows you to say "yes" to more projects and respond faster to market trends without needing a separate machine for every job.

4. What Makes Kawashima's High-Speed Machines So Reliable?

Is unplanned downtime killing your production schedule? Every unexpected stop costs you money and puts your delivery deadlines at risk. You need a machine that is built from the ground up for non-stop reliability.

Kawashima, a Japanese brand, is famous for precision and long-term reliability. Their high-speed vertical packers, like their twin-motion concept machines, are built for durability and consistent performance, minimizing downtime in high-volume operations.

The Japanese engineering philosophy that Kawashima embodies is all about long-term operational excellence. Where some machines focus only on top speed, Kawashima focuses on consistency and uptime. Their machines are built with high-precision components and a design that prioritizes smooth, stable operation over many years. This is perfect for production lines that run the same product for long, continuous shifts. The idea is to minimize vibrations, reduce wear and tear on parts, and eliminate the small errors that can lead to a line stoppage. For a production manager whose main goal is to meet a weekly quota with as few interruptions as possible, this emphasis on rock-solid reliability is incredibly valuable. It's an investment in predictable, consistent output shift after shift.

5. Why is Smart Weigh the Specialist in Dual VFFS Technology?

Are you looking for more than just a piece of equipment? You need a partner who understands your challenges with speed, space, and cost. An off-the-shelf solution might not give you the competitive edge you need.

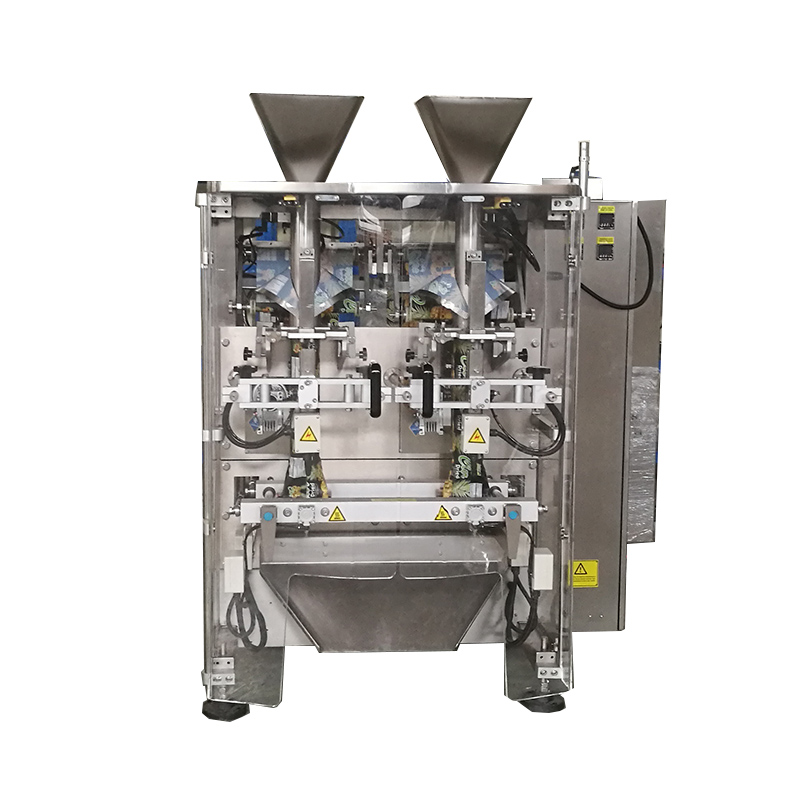

We are experts in dual VFFS technology. Our machines are now in their third generation, specifically designed from customer feedback for higher speeds, a smaller footprint, and unmatched reliability. We provide a complete, cost-effective solution.

Here at Smart Weigh, we provide complete solutions. Our third-generation dual VFFS is the result of years of listening to our customers and solving their real-world problems. We focused on the three things that matter most to production managers: stability, cost, and performance.

Unmatched Stability: The 24/7 Workhorse

The most important feature of any machine is its ability to run without stopping. We designed our dual VFFS for extreme stability. We have customers who run our machines 24 hours a day, 7 days a week, with only planned stops for maintenance. This is because we use high-quality components and a robust design that has been proven on factory floors worldwide. This level of reliability means you can count on meeting your production targets every single day.

A Cost-Effective, High-Performance Solution

High performance should not mean an impossibly high price. The true cost of a machine is its total cost of ownership. Our dual VFFS is efficient, reducing film waste and product giveaway. Its stability minimizes expensive downtime and repair costs. By doubling your output in a small footprint, it also saves valuable factory space. This combination delivers a faster return on your investment.

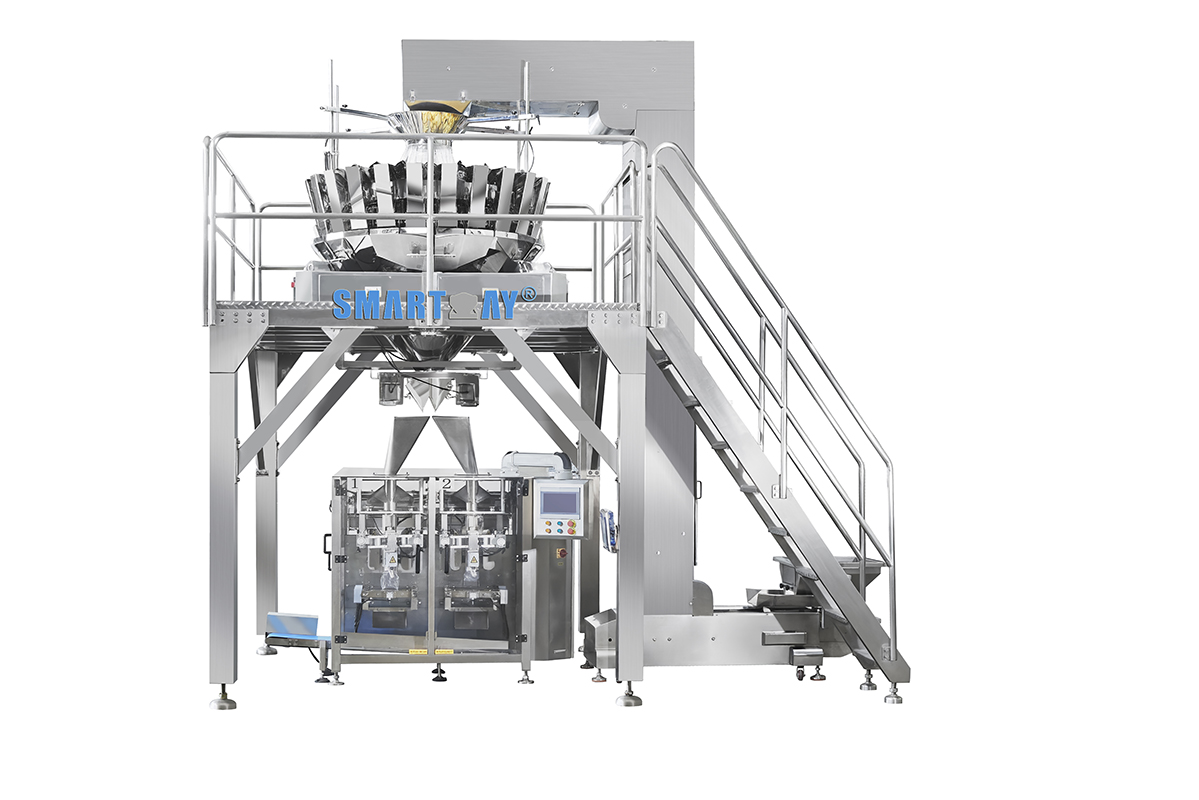

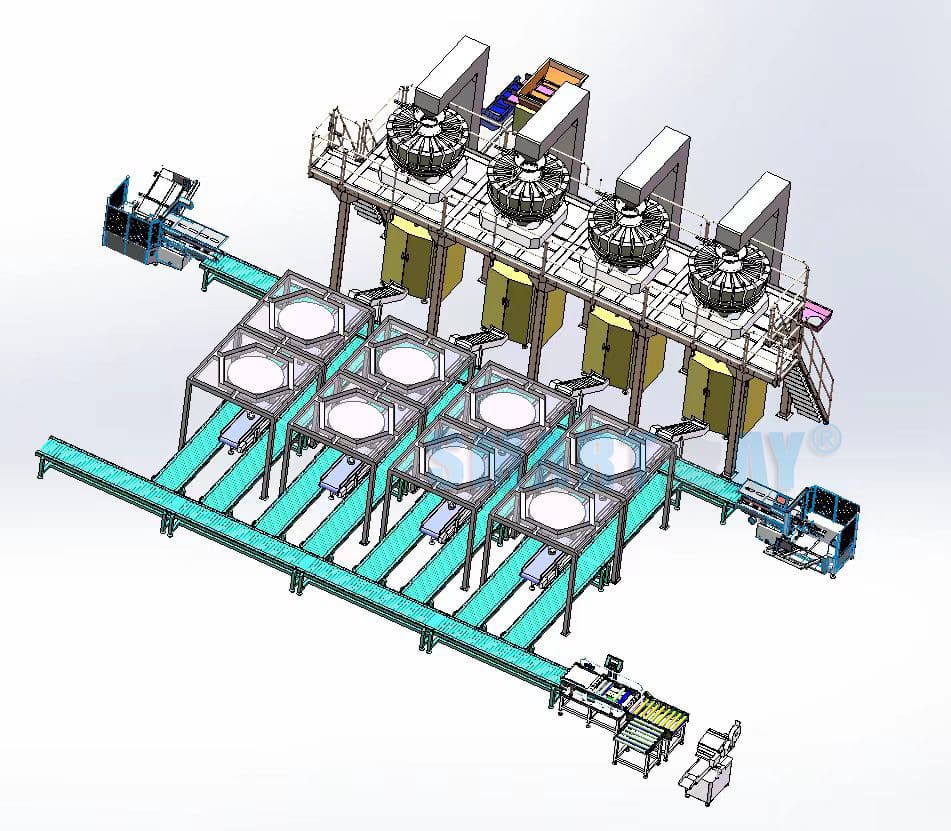

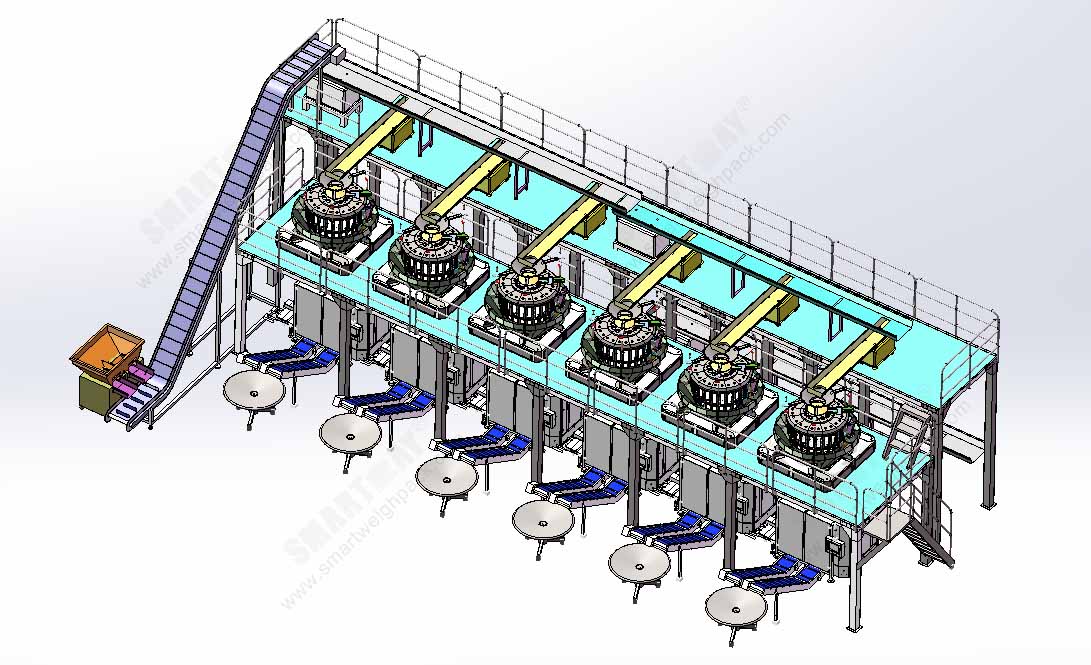

Complete Turnkey Packing Lines

Our expertise goes beyond just the duplex VFFS machine itself. We provide complete, integrated packing lines for granules, powders, and even liquids. This means we design and supply everything from the initial product feeding and weighing, through filling and sealing, to final labeling, cartoning, and palletizing. You get a seamless system from a single, expert partner, eliminating the headaches of coordinating multiple vendors and ensuring all components work together perfectly.

Conclusion

Choosing the right dual VFFS machine depends on your specific needs for speed, space, and reliability. The top brands offer great solutions, ensuring you can find the perfect fit.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine