Company Advantages1. The manufacture of Smartweigh Pack is of professionalism. The multistage production process is adopted. Its design, production, assembly, and testing will be controlled by separate teams. Excellent performance is achieved by the smart Weigh packaging machine

2. With its foreseeable development prospects, this product is worth expanding over the market. More packs per shift are allowed due to the improvement of weighing accuracy

3. The product is reliable in operation. It can always perform consistently according to the given instructions and continuously work without any deviations. Smart Weigh pouch fill & seal machine can pack almost anything into a pouch

4. Excellent hardness and elongation are its advantages. It has gone through one of the stress-strain tests, namely, tension testing. It will not break with increasing tensile load. Smart Weigh pouch helps products to maintain their properties

5. The product is resistant to the corrosive medium, including alkali and salt. It has been treated with plating and painting to enhance its chemical corrosion resistance. Smart Weigh sealing machine is compatible with all standard filling equipment for powder products

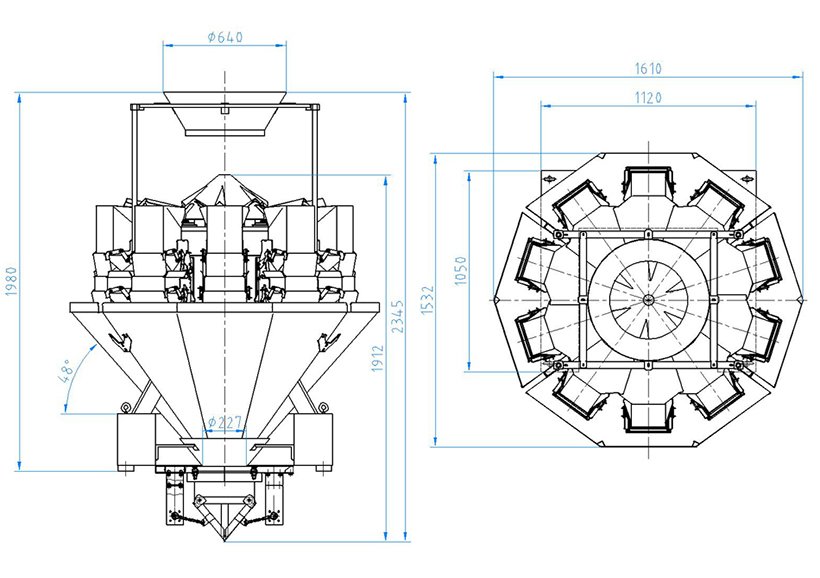

Model | SW-ML10 |

Weighing Range | 10-5000 grams |

Max. Speed | 45 bags/min |

Accuracy | + 0.1-1.5 grams |

Weigh Bucket | 0.5L |

Control Penal | 9.7" Touch Screen |

Power Supply | 220V/50HZ or 60HZ; 10A; 1000W |

Driving System | Stepper Motor |

Packing Dimension | 1950L*1280W*1691H mm |

Gross Weight | 640 kg |

◇ IP65 waterproof, use water cleaning directly, save time while cleaning;

◆ Four side seal base frame ensure stable while running, big cover easy for maintenance;

◇ Modular control system, more stability and lower maintenance fees;

◆ Rotary or vibrating top cone can be selected;

◇ Load cell or photo sensor checking to satisfy different requirements;

◆ Preset stagger dump function to stop blockage;

◇ 9.7' touch screen with user friendly menu, easy to change in different menu;

◆ Checking signal connection with another equipment on the screen directly;

◇ Food contact parts disassembling without tools, which is easier to clean;

Part1

Rotary top cone with unique feeding device, it can separate salad well;

Full dimplete plate keep less salad stick on the weigher.

Part2

5L hoppers are design for salad or big weght products volume;

Each hopper is exchangeable.;

It is mainly apply in automatic weighing various granular products in food or non-food industries, such as potato chips, nuts, frozen food, vegetable, sea food, nail, etc.

Guangdong Smart Weigh Packaging Machinery Co., Ltd has attended many influential international exhibition and highly recognized by customers.

2. Our sales team is dedicated to helping our business grow. With their years of industry experience, they are also able to help our customers to achieve their business goals.

3. We take care of each step in the production process to make sure every stage is done meeting regulations for protecting the environment.