Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Over the years, Smart Weigh has been offering customers high-quality products and efficient after-sales services with the aim of bringing unlimited benefits for them. dry product filling machine We will do our best to serve customers throughout the whole process from product design, R&D, to delivery. Welcome to contact us for further information about our new product dry product filling machine or our company.The best way to keep the nutrient is by dehydrating the food water content, compared to food drying, canning, freezing, and salting, said the nutritionists.

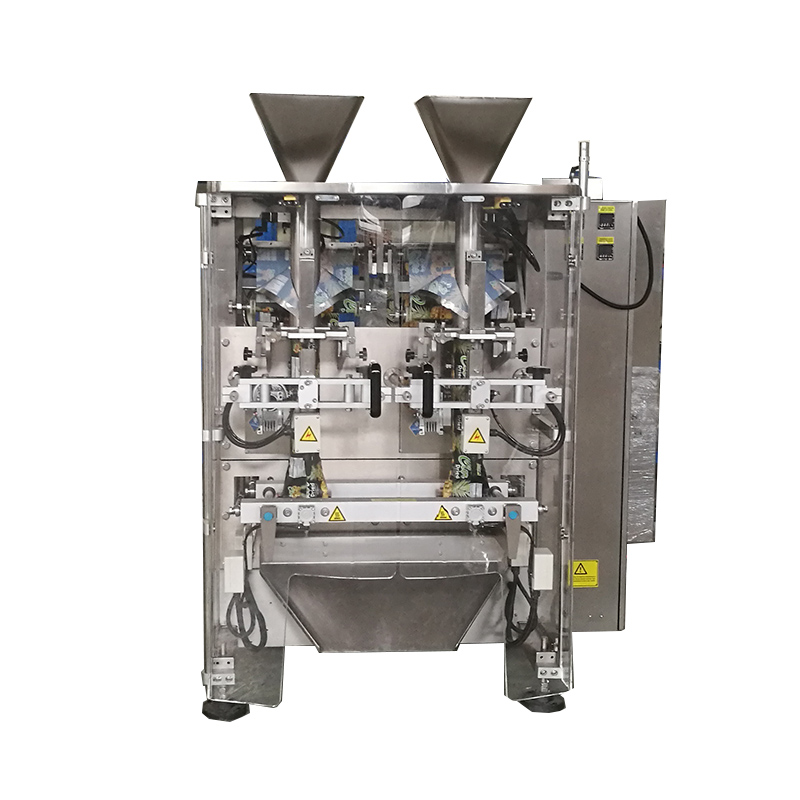

| NAME | Twin VFFS Machine with 24-heads-Weigher |

| Capacity | 120 bags/min according to the bag sizes it is also affected by the quality of film and bag length |

| Accuracy | ≤±1.5% |

| Bag size | (L)50-330mm (W)50-200mm |

| Film width | 120 - 420mm |

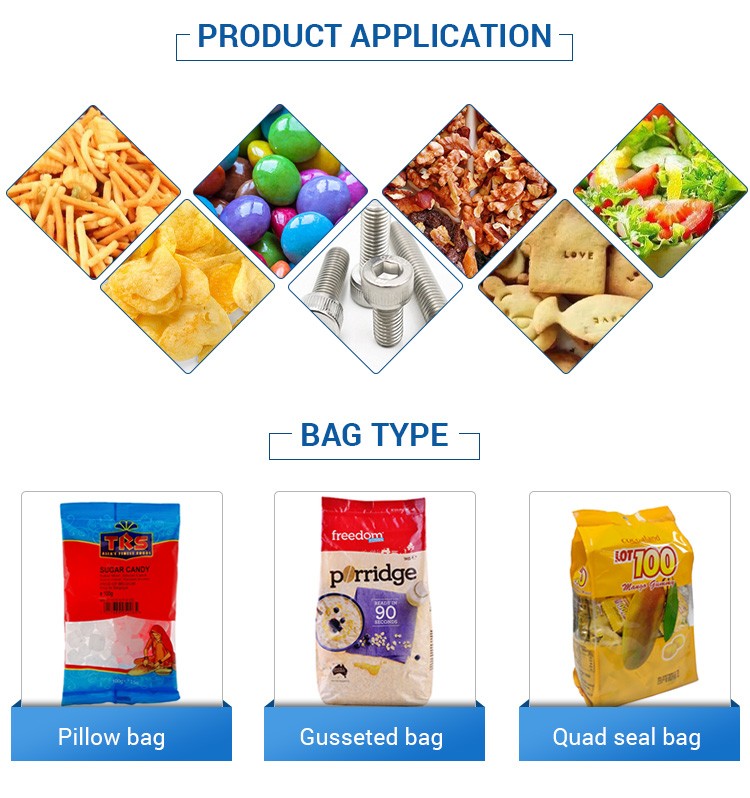

| Bag type | Pillow bag( optional: gusseted bag, strip bag, bags with euroslot) |

| Pulling belt type | Double-belts pulling film |

| Filling range | ≤ 2.4L |

| Film thickness | 0.04-0.09mm the best is 0.07-0.08 mm |

| Film material | thermal composite material., like BOPP/CPP, PET/AL/PE etc |

| Size | L4.85m * W 4.2m * H4.4m ( for one system only) |

Smart Weigh’s double VFFS machine integrates 24-head multihead weighers to deliver up to 120 precision-filled bags per minute of popcorn, corn curls or any fragile puffed snack. Each weaver-style stainless-steel bucket handles 0.5-100 g portions with ±0.2 g accuracy; gentle vibration and soft-drop chutes keep products intact. Dual servo film-pulling stations form pillow, gusseted or quad-seal pouches from laminated film, while auto edge-positioning, date-coding, nitrogen flushing and tear-notch punching run in continuous motion. A 10-inch HMI stores 99 recipes; IP65 wash-down frame, tool-free changeover and remote diagnostics slash downtime and labor. This high speed VFFS Machine with weigher giving snack producers speed, accuracy and gentle handling in one turnkey solution.

Advantages

1. Ultra-high throughput: twin VFFS with 24-head weighers synchronize with dual VFFS tubes to reach 120 finished bags per minute, effectively doubling the capacity of single-lane machines and meeting peak season demand without extra floor space.

2.Gentle product handling: soft-drop buckets, vibration dampening and cushioned discharge chutes protect fragile popcorn and puffed snacks from edge chipping or crushing, maintaining the airy texture consumers expect.

3. Flexible pack styles: quick-change forming collars, servo-driven draw-bars and interchangeable sealing jaws allow pillow, gusseted or quad-seal pouches to be produced on the same line with tool-free changeover in under five minutes.

The double vertical form fill seal machine have low cost high gain, high speed and efficiency MITSUBUSHI PLC control system, large touchscreen, convenient to operateFilm drawing down system and horizontal sealingcontrolled by servo motor minimize the loss withcomplete automatic warn protection functionIt can complete feeding, measuring, filling, sealing,date printing, charging(exhausting), countingfinished product delivery when it equips with feedingand measuring equipment.

The double VFFS packing machine with 24-head weighers is engineered for high-throughput, gentle handling of fragile snacks. It fills pillow, gusseted or quad-seal pouches with crisps, puffed food, popcorn, cheese or kettle corn; extruded corn curls, rings, balls; rice, wheat or multigrain puffs; and seasoned tortilla chips. The 120-bags-per-minute speed supports single-serve retail bags, family-size pouches, multipack inner sachets and promotional mini packs. Nitrogen flushing preserves crispness for shelf-ready, export or e-commerce channels.

Whether you need a popcorn packing machine, crisp packaging machine or granule packing machine which is suitable for loose rounded in the food, chemical and other industrial, this vertical packaging machine can satisfy you!

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved