Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Smart Weigh has developed to be a professional manufacturer and reliable supplier of high-quality products. Throughout the whole production process, we strictly implement the ISO quality management system control. Since established, we always adhere to independent innovation, scientific management, and continuous improvement, and provide high-quality services to meet and even exceed customers' requirements. We guarantee our new product automatic weighing will bring you a lot of benefits. We are always standby to receive your inquiry. automatic weighing We have professional employees who have years of experience in the industry. It is them that provides high-quality services for customers all over the world. If you have any questions about our new product automatic weighing or want to know more about our company, feel free to contact us. Our professionals would love to help you at any time.The dehydrating food preserves the natural nutrients that they contain. The simple water content removing process controlled by warm air circulation has no influence on its original ingredients.

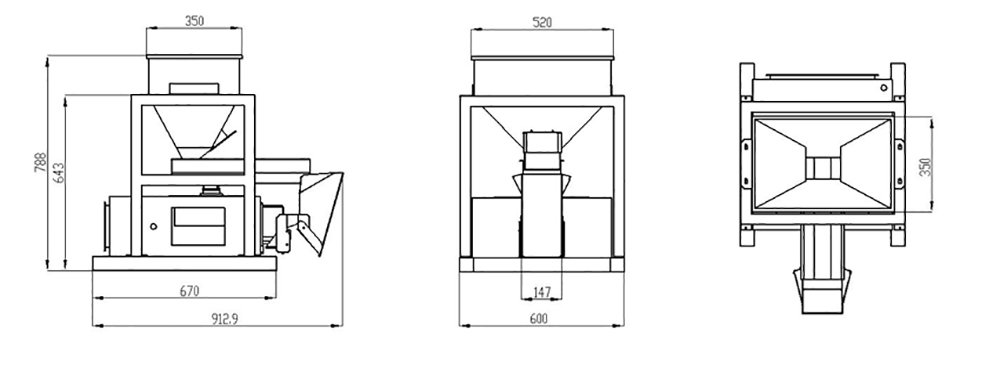

Model | SW-LW1 |

Single Dump Max. (g) | 20-1500 G |

Weighing Accuracy(g) | 0.2-2g |

Max. Weighing Speed | + 10 dumps per minute |

Weigh Hopper Volume | 2500ml |

Control Penal | 7" Touch Screen |

Power Supply | 220V/50/60HZ 8A/800W |

Packing Dimension(mm) | 1000(L)*1000(W)1000(H) |

Gross/Net Weight(kg) | 180/150kg |

Sometimes, linear weighers are able to weigh products seasoning powder, ground coffee, pet food and etc, the most efficient way is to contact our sales team, getting your packaging solution.

◇ Adopt no-grade vibrating feeding system to make products flowing more fluently;

◆ The program can be freely adjusted according to production condition;

◇ Adopt high precision digital load cell;

◆ Stable PLC or modular system control;

◇ Color touch screen with Multilanguage control panel;

◆ Sanitation with stainless steel 304 construction

◇ The parts contacted products can be easily mounted without tools;

1. Slow speed and big weighing tolerance;

2. Limited factory area for the machine;

3. Hard to control filling time;

4. Don't know when should feed products into storage hopper

1. Linear weighed weighs as to the preset weight then fills automatically, weighing tolerance control within 1-3 grams;

2. Small volume, the weigher is only 1 CBM;

3. Work with foot panel, easy to control every filling time;

4. The weigher is with a photo sensor, if it works with conveyor, weigher will send a signal to conveyor feed products.

Linear weigher is a type weighing machine, surely it could equips with various automatic bagging machine, such as vertical form fill seal machine, premade pouch packing machine or carton packing machine. But you already have the manual sealing machine, we offer foot pedal which controlling weigher filling.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved