Company Advantages1. Performance of 4 head

linear weigher is significantly improved after Smart Weigh Packaging Machinery Co., Ltd start using sealing machine materials. Smart Weigh

packing machines are of high efficiency

2. The use of this product has greatly improved labor efficiency and reduced the intensity of talent work. Therefore, it is considered to be an indispensable product of the manufacturer. Less maintenance is required on Smart Weigh packing machines

3. The product has enough hardness. It is able to resist deformation, which is determined by a standard test where the surface resistance to indentation is measured. The packing process is constantly updated by Smart Weigh Pack

4. The product stands out for its superior corrosion resistance. The fiberglass materials are able to withstand acid and alkali and the steel parts are hot-dip galvanized. Smart Weigh sealing machine offer some of the lowest noise available in the industry

5. A huge amount of labor cost can be saved by using this product. Unlike the traditional drying methods which need frequent drying in the sun, the product features automation and smart control. Smart Weigh packing machine features precision and functional reliability

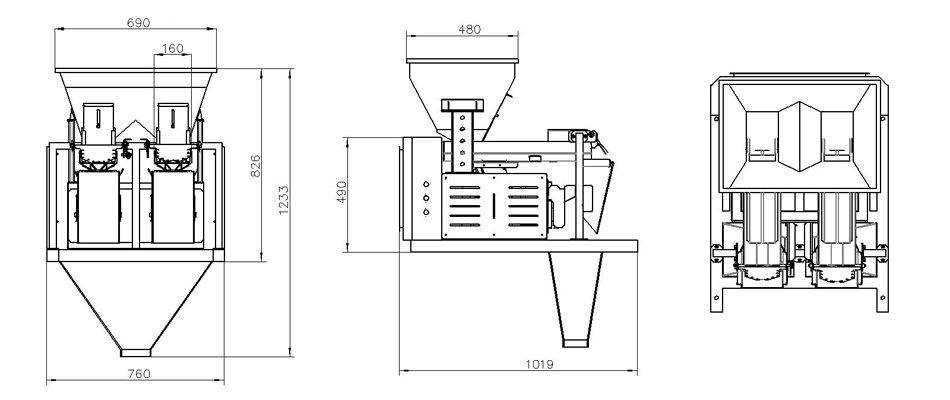

Model | SW-LW2 |

Single Dump Max. (g) | 100-2500 G

|

Weighing Accuracy(g) | 0.5-3g |

Max. Weighing Speed | 10-24wpm |

Weigh Hopper Volume | 5000ml |

Control Penal | 7" Touch Screen |

Max. mix-products | 2 |

Power Requirement | 220V/50/60HZ 8A/1000W |

Packing Dimension(mm) | 1000(L)*1000(W)1000(H) |

Gross/Net Weight(kg) | 200/180kg |

◇ Make mix different produts weighing at one discharge;

◆ Adopt no-grade vibrating feeding system to make products flowing more fluently;

◇ Program can be freely adjusted according to production condition;

◆ Adopt high precision digital load cell;

◇ Stable PLC system control;

◆ Color touch screen with Multilanguage control panel;

◇ Sanitation with 304﹟S/S construction

◆ The parts contacted products can be easily mounted without tools;

Part1

Separate storage feeding hoppers. It can feed 2 diffrent products.

Part2

Moveable feeding door, easy to control product feeding volume.

Part3

Machine and hoppers are made of stainless steel 304/

Part4

Stable load cell for better weighing

This part can be easily mounted without tools;

It is suitable for smaller granule and powder, like rice, sugar, flour, coffee powder etc.

Since establishment, Smart Weigh Packaging Machinery Co., Ltd has provided superior design and production of sealing machine . We are recognized as one of the leaders in the industry. We have established long-term cooperation with customers. We have built up mutual trust and achieved a win-win situation over the years. Time has proved to us that they are our loyal customers.

2. We operate advanced manufacturing facilities. Equipped with world-class production lines and machines, they are able to make products that meet the highest standards of quality, precision, and performance.

3. Our factory is well-equipped. We continue to invest heavily in the latest equipment such as high-speed equipment, to ensure satisfying quality, capacity, time-to-market, and costs. We regard industry sustainability as our main goal. Under this goal, we will spare no effort to realize a greener production model, in which resources are utilized fully and emissions are greatly cut.