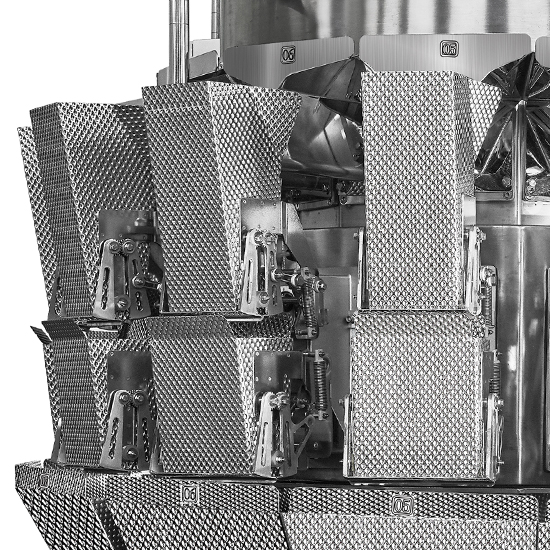

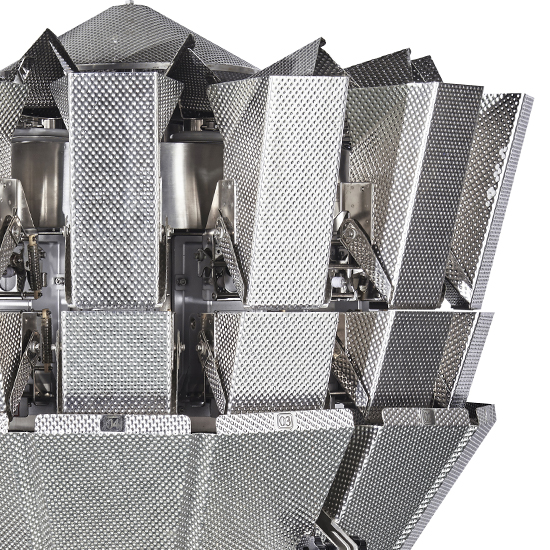

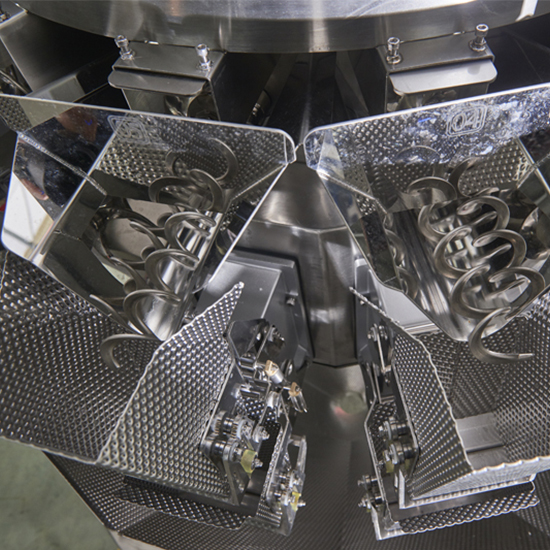

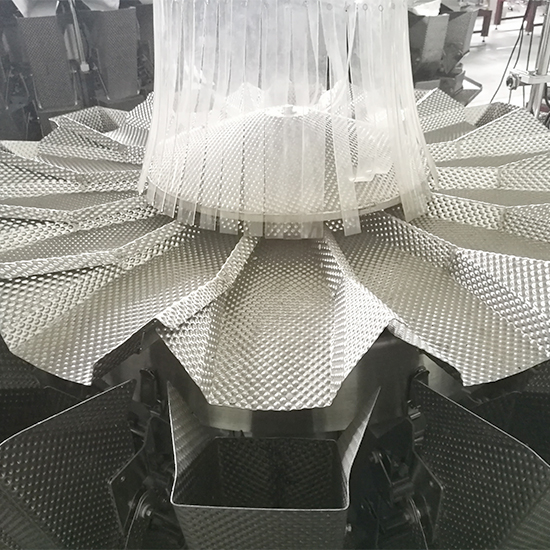

Standard 10 Head Multihead Weigher

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved