Company Advantages1. Smart Weigh

linear weigher china is fabricated using common mechanical processing methods, including benching, lathe machining, drilling, chipping, CNC machining, hone machining, and so on.

2. has the properties of linear weigher china as compared with other similar products.

3. There are complete product specifications for to meet the needs of different users.

4. This features effectively enhance the popularity and reputation of the product.

5. It has established a good reputation within years of development.

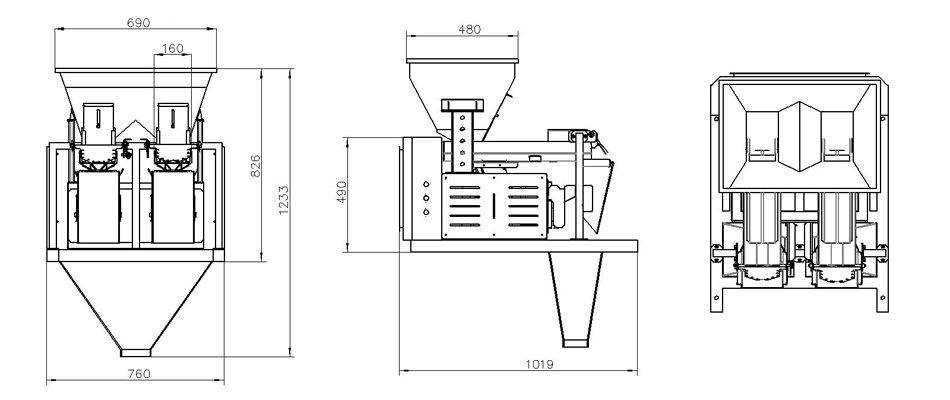

Model | SW-LW2 |

Single Dump Max. (g) | 100-2500 G

|

Weighing Accuracy(g) | 0.5-3g |

Max. Weighing Speed | 10-24wpm |

Weigh Hopper Volume | 5000ml |

Control Penal | 7" Touch Screen |

Max. mix-products | 2 |

Power Requirement | 220V/50/60HZ 8A/1000W |

Packing Dimension(mm) | 1000(L)*1000(W)1000(H) |

Gross/Net Weight(kg) | 200/180kg |

◇ Make mix different produts weighing at one discharge;

◆ Adopt no-grade vibrating feeding system to make products flowing more fluently;

◇ Program can be freely adjusted according to production condition;

◆ Adopt high precision digital load cell;

◇ Stable PLC system control;

◆ Color touch screen with Multilanguage control panel;

◇ Sanitation with 304﹟S/S construction

◆ The parts contacted products can be easily mounted without tools;

Part1

Separate storage feeding hoppers. It can feed 2 diffrent products.

Part2

Moveable feeding door, easy to control product feeding volume.

Part3

Machine and hoppers are made of stainless steel 304/

Part4

Stable load cell for better weighing

This part can be easily mounted without tools;

It is suitable for smaller granule and powder, like rice, sugar, flour, coffee powder etc.

Smart Weigh Packaging Machinery Co., Ltd is the first large manufacturer in China specializing in producing .

2. Smart Weigh Packaging Machinery Co., Ltd has achieved fruitful technical outcomes by cause of its strong technical base.

3. What is most proud of Smart Weigh Packaging Machinery Co., Ltd is that we have outstanding

packing machine talents who are working hard to build a 'world-class linear weigher enterprise group'. Contact! linear weigher china is the core of the Smart Weigh Packaging Machinery Co., Ltd's business and the foundation for the its development. Contact! In accordance with the requirements of high quality development, Smart Weigh Packaging Machinery Co., Ltd will adhere to wrapping machine in the linear weigher single head production. Contact!

Product Comparison

This highly-competitive

multihead weigher has the following advantages over other products in the same category, such as good exterior, compact structure, stable running, and flexible operation.Compared with similar products, Smart Weigh Packaging's multihead weigher is more advantageous in the following aspects.

Enterprise Strength

-

With a complete service system, Smart Weigh Packaging is dedicated to providing consumers with comprehensive and thoughtful services.