Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Smart Weigh offers several popcorn packaging solutions, no matter it is for bags, pouches, jars and other. You can find the right machines here.

SEND INQUIRY NOW

There are different types of popcorn packaging solutions available, each with its own unique features and benefits. Some common types of popcorn packing machines are:

1. Multihead Weigher & Vertical Form Fill Seal Machine (VFFS)

2. Multihead Weigher & Pre-made Bagging Machine

3. Volumetric Cup Filler Vertical Form Fill Seal Machine

4. Jar Filling Packing Machine:

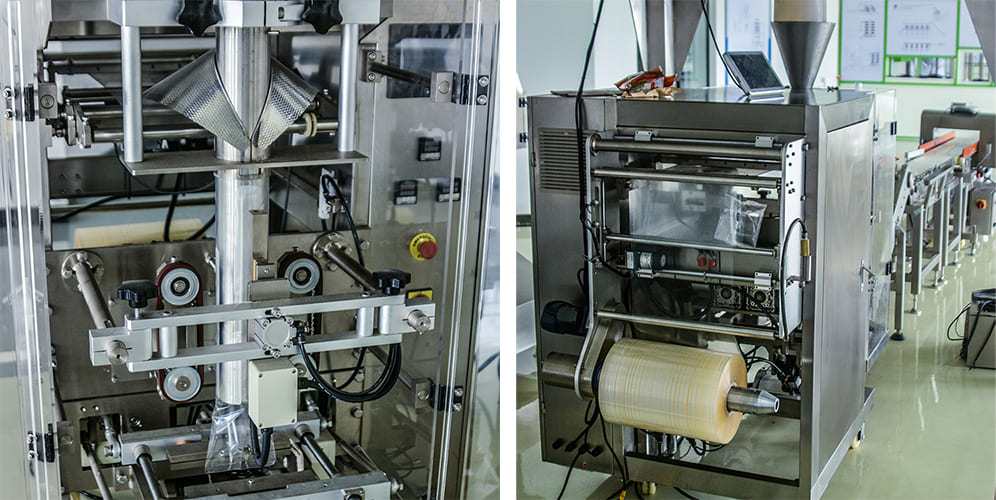

A multihead weigher VFFS (Vertical Form Fill Seal) machine for popcorn is a type of packaging machine that is designed to accurately weigh and package popcorn in individual bags from the roll film. This machine is typically used in popcorn production facilities and is capable of handling a wide variety of popcorn types and sizes.

The multihead weigher VFFS machine works by using multiple weighing heads to accurately measure the desired amount of popcorn for each package. The machine then uses a vertical form fill seal process to form the pillow bag or gusset bag, fill it with the measured amount of popcorn, and then seal it to ensure freshness and protect it from environmental factors such as moisture, oxygen, and light.

SPECIFICATION

| Weighing Range | 10-1000 grams (10 head weigher) |

|---|---|

| Hopper Volume | 1.6L |

| Speed | 10-60 packs/min (standard), 60-80 packs/min (high speed) |

| Accuracy | ±0.1-1.5 g |

| Bag Style | Pillow bag, gusset bag |

| Bag Size | Length 60-350mm, width 100-250mm |

STANDARD FEATURES

1. Weigh filler - multihead weigher is flexible to set actual weight, speed and accuracy on touch screen;

2. Multihead weigher is modular control, easy to maintain and have longer working life;

3. VFFS is PLC controlled, more stable and accuracy output signal, bag-making and cutting;

4. Film-pulling with servo motor for precision;

5. Open door alarm and stop machine running in any condition for safety regulation;

6. Film in roller can be locked and unlocked by air, convenient while change film.

MACHINE DETAILS

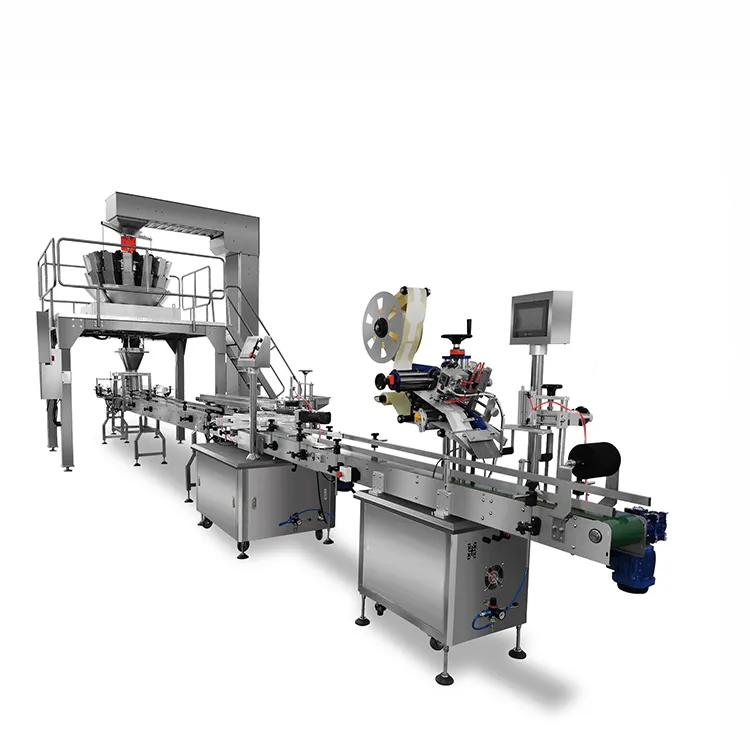

A multihead weigher premade bag packaging machinery for popcorn is a type of packaging machine that is designed to weigh and package popcorn in pre-made popcorn bags or pouches, doypack and zipper bags, some premade bags could be put in Micro-wave oven.

The multihead weigher premade bag packing machine works by using multiple weighing heads to accurately measure the desired amount of popcorn for each pre-made bag or pouch. The machine then uses a bag opening mechanism to open the pre-made bag or pouch, and then fill it with the measured amount of popcorn. Once the bag is filled, the machine will then seal the pouch.

SPECIFICATION

| Weighing Range | 10-2000g (14 head) |

|---|---|

| Hopper Volume | 1.6L |

| Speed | 5-40 bags/min(standard), 40-80 bags/min (dual 8-station) |

| Accuracy | ±0.1-1.5 g |

| Bag Style | Premade bag, doypack, zipper bag |

| Bag Size | Length 160-350mm, width 110-240mm |

FEATURES

1. Different weight only need to preset on touch screen of multihead weigher for popcorn filling;

2. 8 station holding pouches finger can be adjusted on the screen, fit for different sizes of pouch and convenient for change bag size;

3. Offer 1 station premade bag packing machine for low capacity request.

MACHINE DETAILS

The volumetric cup filler VFFS machine works by using pre-set volumetric cups to measure the desired volume of popcorn for each bag. The measure part is always compacted on VFFS machine, if you have different weight, purchase extra volume cups for exchange are OK.

SPECIFICATION

| Weigh Range | 10-1000ml (customize depends on your project) |

|---|---|

| Speed | 10-60 packs/min |

| Bag Style | Pillow bag, gusset bag |

| Bag Size | Length 60-350mm, width 100-250mm |

1. Simple design weigh filler - volumetric cup, low cost and high speed;

2. Easy to change different volume of cups (if you have different packing weight);

3. VFFS is PLC controlled, more stable and accuracy output signal, bag-making and cutting;

4. Film-pulling with servo motor for precision;

5. Open door alarm and stop machine running in any condition for safety regulation;

6. Film in roller can be locked and unlocked by air, convenient while change film.

MACHINE DETAILS

A jar filling packaging equipment is a piece of equipment designed to quickly and efficiently weigh, fill and seal jars with popcorn. It typically features an automated process with adjustable settings for controlling the amount of product that is filled into each container. The machine also usually has a user-friendly interface for easily selecting desired settings.

SPECIFICATION

| Weighing Range | 10-1000g (10 head weigher) |

|---|---|

| Accuracy | ±0.1-1.5g |

| Package Style | Tinplate Can, Plastic Jar, Glass Bottle, etc |

| Package Size | Diameter=30-130 mm, Height=50-220 mm (depends on machine model) |

FEATURES

1. Semi automatic or fully automatic jar filling packing machine for choices;

2. Semi automatic jar filling machine can auto weigh and fill containers with nuts;

3. Fully automatic jar packing machine can auto weigh, fill, seal and label.

As we see that, there are different models for choices, the most effient way is to contact our sales team, they will offer you the best packaging solution for popcorn within your budget!

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Get Free Quotation Now!

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved