Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

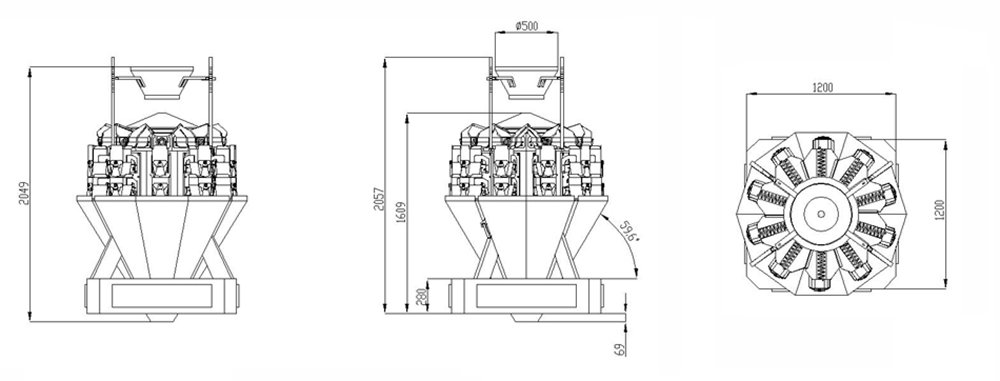

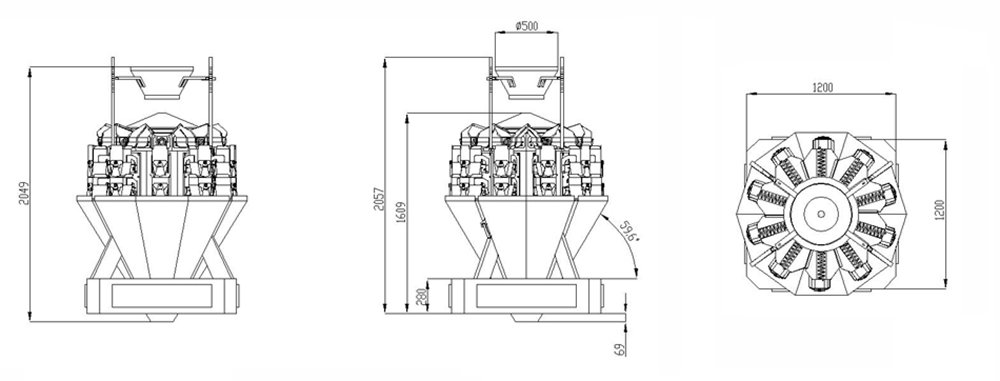

Model | SW-M10S |

Weighing Range | 10-2000 grams |

Max. Speed | 35 bags/min |

Accuracy | + 0.1-3.0 grams |

Weigh Bucket | 2.5L |

Control Penal | 7" Touch Screen |

Power Supply | 220V/50HZ or 60HZ; 12A;1000W |

Driving System | Stepper Motor |

Packing Dimension | 1856L*1416W*1800H mm |

Gross Weight | 450 kg |

◇ IP65 waterproof, use water cleaning directly, save time while cleaning;

◆ Auto feeding, weighing and delivery sticky product into bagger smoothly

◇ Screw feeder pan handle sticky product moving forward easily

◆ Scraper gate prevents the products from being trapped into or cut. The result is more precise weighing

◇ Modular control system, more stability and lower maintenance fees;

◆ Production records can be checked at anytime or download to PC;

◇ Rotary top cone to separate the sticky products onto linear feeder pan equally, to increase speed & accuracy;

◆ All food contact parts can be take out without tool, easy cleaning after daily work;

◇ Special heating design in electronic box to prevent high humidity and frozen environment;

◆ Multi-languages touch screen for various clients, English, French, Spanish, Arabic etc;

◇ PC monitor production status, clear on production progress (Option).

It is mainly apply in automatic weighing various granular products in food or non-food industries, such as potato chips, nuts, frozen food, vegetable, sea food, nail, etc.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved