The Star of ALLPACK Indonesia 2025: Smart Weigh’s 180 Packs/Min Packaging Line

Struggling to boost production output with limited factory floor space? This common challenge can halt growth and hurt your bottom line. We have a solution that offers more speed in less space.

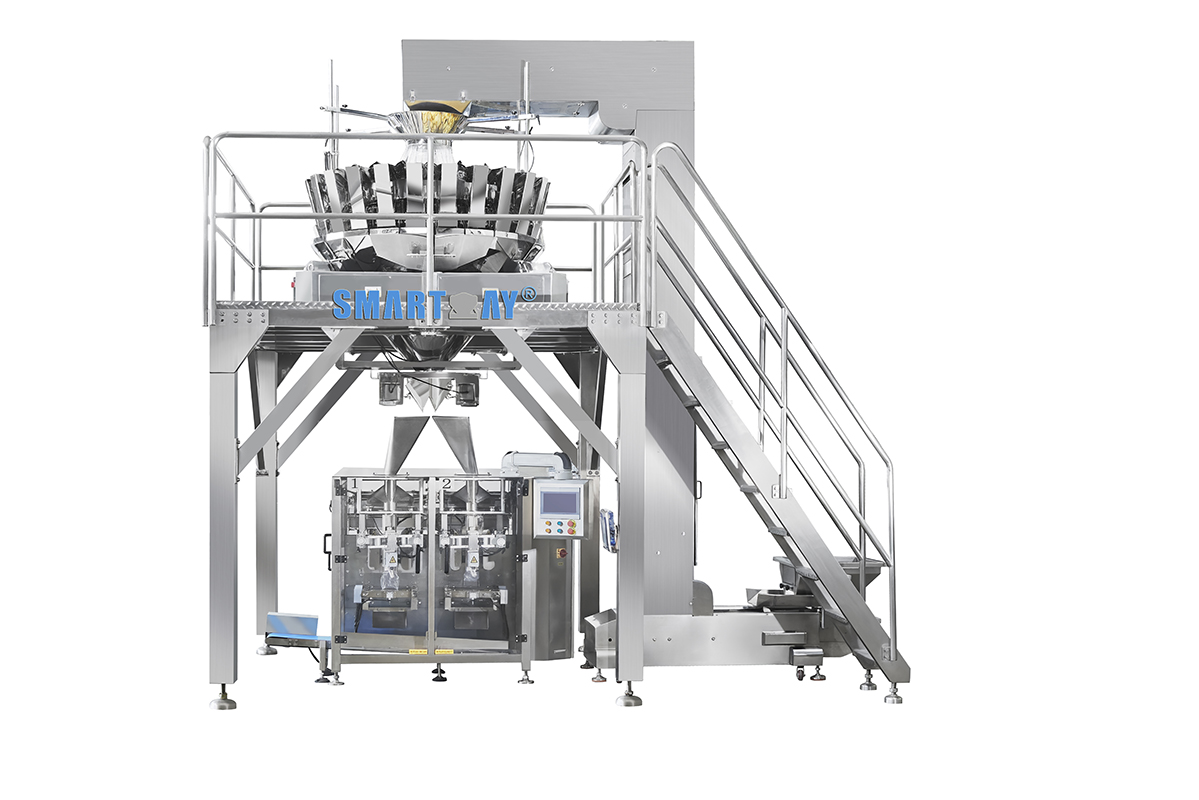

The answer is a fully integrated twin discharge multihead weigher with a duplex VFFS machine. This innovative system synchronizes weighing and packing to handle two bags simultaneously, effectively doubling your output up to 180 packs per minute within a surprisingly compact footprint.

We just returned from ALLPACK Indonesia 2025 during 21-24 October, and the response to this exact solution was incredible. The energy at our booth (Hall D1, Booth DP045) confirmed what we already knew: the demand for efficient, high-speed automation in the ASEAN market is accelerating fast. Seeing the system run live was a game-changer for many visitors, and I want to share with you why it captured so much attention and what it means for the future of food packaging.

What Made Our High-Speed System the Star of the Show?

It's one thing to read about high speeds on a spec sheet. But it is another thing to see it perform flawlessly right in front of you. That's why we showcased a live demo.

Our twin discharge multihead weigher paired with a duplex VFFS system became a major attraction. Visitors witnessed firsthand how it seamlessly weighed and packed two pillow bags at once, hitting speeds up to 180 packs per minute with remarkable stability and sealing consistency.

The booth was constantly busy with production managers and factory owners who wanted to see the system in action. They weren't just watching; they were analyzing the stability, the noise level, and the quality of the finished bags. The live demo was our way of proving that speed and accuracy can exist without compromise. Here’s a breakdown of the components that make it possible.

The Power of Twin Discharge Weighing

The heart of the system is the twin discharge multihead weigher. Unlike a standard weigher that feeds a single packaging machine, this one is designed with two outlets. It accurately portions out the product and sends it down two separate channels at the same time. This dual-lane operation is the key to doubling the number of weighing cycles in the same period.

Duplex VFFS for Double the Output

The weigher's synchronized output feeds directly into a duplex Vertical Form Fill Seal (VFFS) machine. This machine uses two formers and two sealers, essentially operating as two packers in one frame. It forms, fills, and seals two pillow bags simultaneously, turning the double weighments into double the packaged product without needing a second full packaging line.

Unified Control for Simple Operation

We integrated both machines under a single, intuitive touchscreen interface. This allows operators to manage recipes, monitor production data, and adjust settings for the entire line from one central point, simplifying operation and reducing the chance of error.

| Feature | Standard Line | Smart Weigh Twin Line |

|---|---|---|

| Max Speed | ~90 packs/min | ~180 packs/min |

| Weighing Outlets | 1 | 2 |

| VFFS Lanes | 1 | 2 |

| Footprint | X | ~1.5X (not 2X) |

What Was the Market's Reaction to This Technology?

Introducing new technology always comes with a question: will the market see its true value? We felt confident, but the enthusiastic response we received at ALLPACK blew away our expectations.

The feedback was fantastic. We welcomed over 600 visitors from across Southeast Asia and gathered more than 120 qualified leads. Manufacturers from Indonesia, Malaysia, and Vietnam were particularly impressed by the system's speed, compact design, and hygienic construction.

Throughout the five-day exhibition, our booth was a hub of activity. We had deep conversations with people who face production challenges every single day. They didn't just see a machine; they saw a solution to their problems. The feedback focused on tangible benefits that modern food plants urgently need.

Beyond Just Visitor Numbers

The quantity of visitors was great, but the quality of the conversations was even better. We walked away with over 120 qualified leads from companies ready to automate. We also received inquiries from 20 potential distributors and system integrators who want to partner with us to bring this technology to their local markets. It was a clear sign that our vision for high-efficiency packaging aligns perfectly with the region's needs.

Key Advantages Highlighted by Visitors

Three points came up again and again in our conversations:

Compact Footprint: Factory owners loved that they could double output without needing space for two separate lines. Space is a premium asset, and our system maximizes it.

Energy Efficiency: Operating one integrated system is more energy-efficient than running two separate ones, a crucial factor in managing operational costs.

Hygienic Design: The full stainless-steel construction and easy-to-clean design resonated with food producers who must meet strict safety and hygiene standards.

Spreading the Word

The buzz wasn't just limited to the exhibition hall. We were thrilled to see visitors and local media sharing videos of our demo on platforms like TikTok and LinkedIn. This organic interest extended our reach far beyond the event itself, showing the genuine excitement around this technology.

How Are We Building on This Success to Support ASEAN Manufacturers?

A successful trade show is just the starting point. The real work begins now, turning that initial excitement and interest into long-term partnerships and tangible support for our customers.

We are fully committed to the ASEAN market. Building on our success, we are strengthening our local distributor network to provide faster service. We are also launching a localized Bahasa Indonesia website and virtual showroom to make our solutions even more accessible.

The show was also a valuable learning experience for us. We listened carefully to every question and piece of feedback. This information is crucial because it helps us improve not only our technology but also how we support our partners in the region. Our goal is to be more than just a machine supplier; we want to be a true partner in our clients' growth.

Learning from the Show Floor

We identified a few ways to make our demonstrations even better next time, like increasing the amount of demo product for longer continuous runs and using larger screens to display real-time data more clearly. These small adjustments show our commitment to providing a transparent and educational experience for everyone who visits us.

Strengthening Local Support

The most important step we're taking is to expand our local presence. By building a stronger distributor and service network across Southeast Asia, we can ensure our customers receive faster installation, training, and after-sales support. When you need a part or technical assistance, you will have a local expert ready to help.

Making Our Technology More Accessible

To better serve our partners in Indonesia and beyond, we are developing a new section of our website in Bahasa Indonesia. We are also creating an online showroom with real factory demos and customer success stories. This will allow anyone, anywhere, to see our solutions in action and understand how we can help them achieve their goals.

Conclusion

Our time at ALLPACK Indonesia 2025 proved that high-speed, compact automation is what food producers need now. We are excited to help more partners in ASEAN achieve their production goals.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine