Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Guided by scientific and technological innovation, Smart Weigh always keeps outward-oriented and sticks to the positive development on the basis of technological innovation. tray filling machine Having devoted a lot to product development and service quality improvement, we have established a high reputation in the markets. We promise to provide every customer throughout the world with prompt and professional service covering the pre-sales, sales, and after-sales services. No matter where you are or what business you are engaged in, we'd love to help you deal with any issue. If you want to know more details about our new product tray filling machine or our company, feel free to contact us.tray filling machine The design is reasonable, the workmanship is exquisite, the operation is stable, and the quality is excellent. It adopts an intelligent control system, which is easy to operate, convenient to use, beautiful and safe.

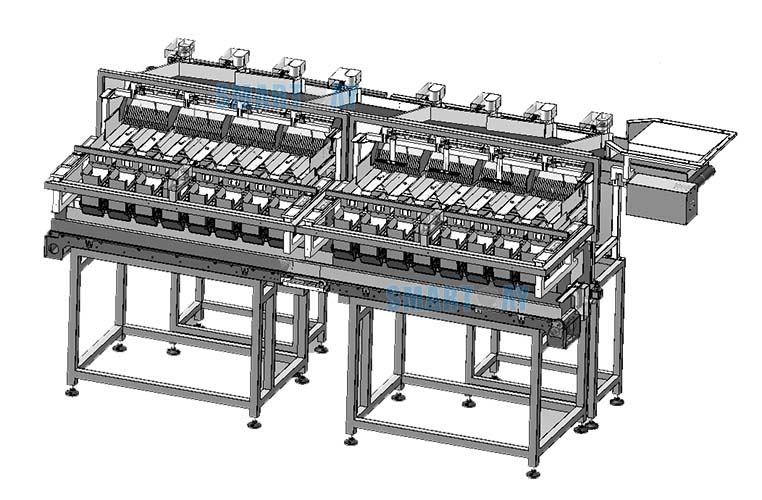

The Smart Weigh blueberry packing equipment is the ideal solution for quickly and accurately weigh and pack blueberries and other berries. It weighs and sorts berries according to preset parameters before gently placing them into customized packages designed to preserve their freshness. Our state-of-the-art design ensures that your delicate fruits are treated with care, with a gentle handling that reduces friction surfaces throughout the weighing and filling process. Enjoy exceptional precision while rest assured knowing your products are packed smoothly to maintain top quality and taste.

Using the latest technology, Smart Weigh designed its blueberry packing machine to provide faster speeds than ever before while maintaining accuracy and high weight capacity. With its easy-to-use menu system, you can rest easy knowing all settings will be accurate every single time. This blueberry packing line also comes equipped with an alarm system which alerts users when there is an overload or other mishap occurring in the packaging process and optimizing the packing process for maximum efficiency in agricultural and food processing settings. Weighing and filling has never been so effortless!

Advantages

1. The blueberry & tomato packing machine increases packing efficiency dramatically through automation, reducing labor costs and human error. Gentle handling mechanisms protect the tomatoes from damage, preserving their quality and aesthetic appeal.

2. Its precise weighing systems guarantee consistent packaging weights, enhancing customer satisfaction. The machine accommodates various packaging formats, ensuring flexibility for different market needs.

3. Sanitary design and easy cleaning further promote food safety standards. With its capability to adapt to changing production volumes.

1. 16 heads berry weigher is available;

2. High speed 130-160 packs per minute, capacity1600-1728kg/hour in 200g in containers;

3. Quick settings on touch screen, can store 99+ packing formula;

4. Work with tray denester, auto separate the empty trays for blueberry packing;

5. Work with labelling printing machine, the machine print the actual weight then label on the tray;

6. This packing machine also can weigh cherry tomatoes, kiwi berries and other weak fruits.

| Model | SW-ALH16 |

| Weigh Head | 16 heads |

| Capacity | Capacity |

| Feeding Pan | High & low into 2 levels |

| Speed | 130-160 trays/min |

| 130-160 trays/min | 2.5L |

| Weighing method | Load cell |

| Accuracy | ± 0.1-5.0 g (Depends on product features) |

| Control Penal | 10" Touch Screen |

| Voltage | 220V/50HZ or 60HZ; Single Phase 2.5kw |

| Drive System | Stepper motor |

In essence, a long-standing tray filling machine organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Regarding the attributes and functionality of the tray filling machine, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Smart Weigh Packaging Machinery Co., Ltd. always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

The buyers of tray filling machine come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

Yes, if asked, we will supply relevant technical details regarding Smart Weigh. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. tray filling machine QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved