Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Over the years, Smart Weigh has been offering customers high-quality products and efficient after-sales services with the aim of bringing unlimited benefits for them. best packaging systems Smart Weigh have a group of service professionals who are responsible for answering questions raised by customers through the Internet or phone, tracking the logistics status, and helping customers solve any problem. Whether you'd like to get more info on what, why and how we do, try our new product - Best Price best packaging systems from China, or would like to partner up, we'd love to hear from you.Looking for a reliable food dehydrator brand? Smart Weigh has got you covered! Our production process follows strict food grade requirements, ensuring the highest quality for your drying needs. We take quality seriously and have enlisted the help of respected third-party inspection institutions to carry out rigorous testing, following industry standards. You can trust us to provide safe and effective dehydrators for your home or business.

The flour starch cassava packaging machine, typically consisting of an auger filler and a premade pouch packing machine, is designed for the efficient and accurate packaging of flour.

Auger Filler:

Function: Primarily used for metering and filling powder products like flour.

Mechanism: It uses a rotating auger to move the flour from the hopper into the pouches. The speed and rotation of the auger determine the amount of product dispensed.

Advantages: Provides precision in measurement, minimizes product waste, and is capable of handling various powder densities.

Premade Pouch Packing Machine:

Function: This machine is used to pack the flour into premade pouches.

Mechanism: It picks up individual premade pouches, opens them, fills them with the product dispensed from the auger filler, and then seals them.

Features: Often includes capabilities like vacuuming out air from the pouch before sealing, which prolongs the shelf-life of the product. It may also have printing options for lot numbers, expiration dates, etc.

Advantages: High efficiency in packing, versatility in handling different pouch sizes and materials, and ensuring airtight seals for product freshness.

Model | SW-PL8 |

Single Weight | 100-3000 grams |

Accuracy | +0.1-3g |

Speed | 10-40 bags/min |

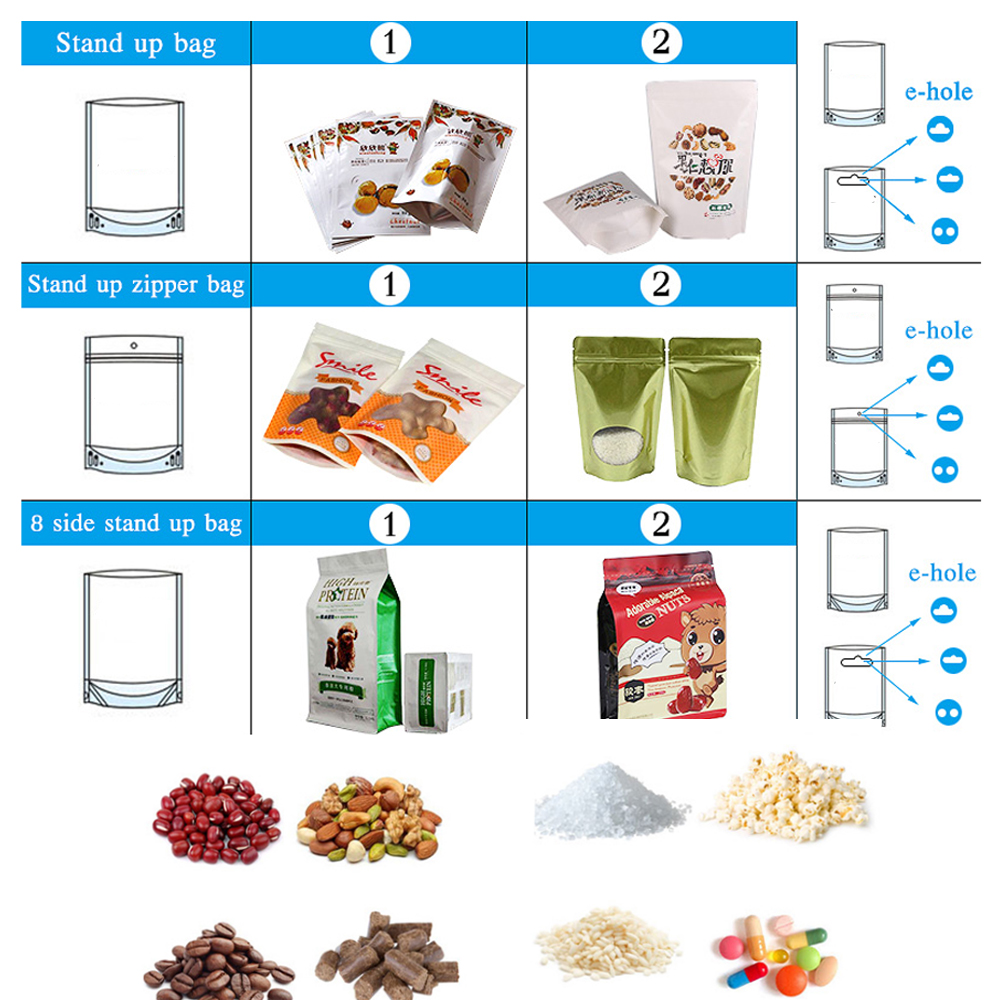

Bag style | Premade bag, doypack |

Bag size | Width 70-150mm; length 100-200 mm |

Bag material | Laminated film or PE film |

Weighing method | Load cell |

Touch screen | 7” touch screen |

Air consumption | 1.5m3/min |

Voltage | 220V/50HZ or 60HZ single phase or 380V/50HZ or 60HZ 3 phase; 6.75KW |

These machines are typically used in a production line for industrial-scale packaging of flour. They can be customized based on the specific requirements of the production line, such as the desired speed of packaging, the volume of flour in each pouch, and the type of pouch material used. Their integration ensures a streamlined process from filling to packaging, significantly enhancing productivity and maintaining consistent quality.

◆ Fully automatic packaging machine packing process from raw materials feeding, weighing, filling, sealing to outputting;

◇ Open door alarm and stop machine running in any condition for safety regulation;

◆ 8 station holding pouches finger can be adjustable, convenient for changing different bag size;

◇ All parts can be taken out without tools.

1. Weighing Equipment: Auger filler.

2. Infeed Bucket Conveyor: screw feeder

3. Packing machine: rotary packing machine.

Flour packaging machine is versatile and can handle a wide range of products beyond just flour, such as coffee powder, milk powder, chili powder and other powder products.

The buyers of best packaging systems come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. best packaging systems QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Smart Weigh Packaging Machinery Co., Ltd. always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

Yes, if asked, we will supply relevant technical details regarding Smart Weigh. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

In essence, a long-standing best packaging systems organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Regarding the attributes and functionality of the best packaging systems, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved