Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

With strong R&D strength and production capabilities, Smart Weigh now has become a professional manufacturer and reliable supplier in the industry. All our products including non food packing line are manufactured based on the strict quality management system and international standards. non food packing line We have been investing a lot in the product R&D, which turns out to be effective that we have developed non food packing line. Relying on our innovative and hard-working staff, we guarantee that we offer customers the best products, the most favorable prices, and the most comprehensive services as well. Welcome to contact us if you have any questions.non food packing line This product boasts exceptional material quality, a well-designed structure, fine workmanship, and high product excellence. It is highly automated, requiring no specialized personnel for maintenance and has a user-friendly interface for easy operation.

Multifunction Laundry Pods With Multihead Weigher Weighing

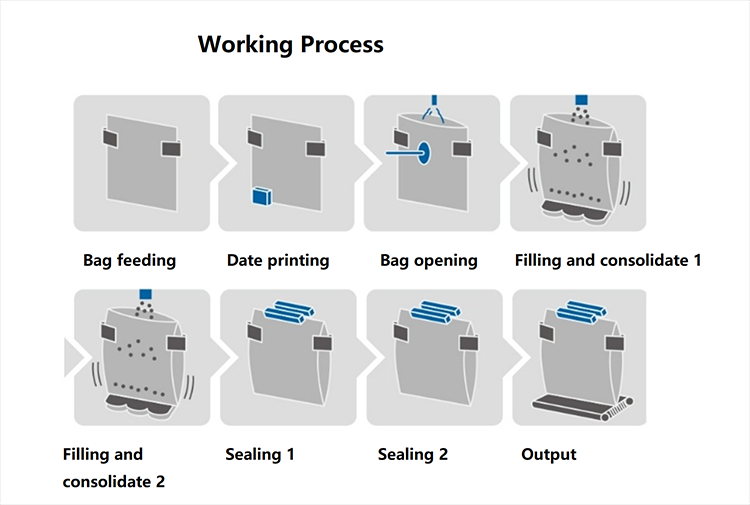

Multifunction premade doypack machine, when combined with a multihead weigher, offer an efficient and precise laundry packaging machines solution. The multihead weigher ensures accurate and consistent weight distribution, enhancing product quality and reducing waste. This detergent pouch packing machine system providing fast and reliable weighing and the automated process minimizes human error and increases productivity. The result is a user-friendly, high-quality laundry pods detergent that meets consumer expectations.

Model | SW-PL7 |

Weighing Range | ≤2000 g |

Bag Size | W: 100-250mm L:160-400mm |

Bag Style | Premade bag with/without zipper |

Bag Material | Laminated film; Mono PE film |

Film Thickness | 0.04-0.09mm |

Speed | 5 - 35 times/min |

Accuracy | +/- 0.1-2.0g |

Weigh Hopper Volume | 25L |

Control Penal | 7" Touch Screen |

Air Consumption | 0.8Mps 0.4m3/min |

Power Supply | 220V/50HZ or 60HZ; 15A; 4000W |

Driving System | Servo Motor |

Cartoning Machines For Pods In Individual Bags

1. 304 stainless steel.

2. Touch screen display, easy to use and maintain.

3. PLC control, excellent performance and long life.

4. High-precision intelligent thermostat to ensure stable temperature control.

5. Simple design, low loss.

6. Servo control stretch film bag making

7. Pneumatic or servo controlled horizontal sealing system.

8. Equipped with thermal printer, automatic printing of date and batch number.

9. Automatic tracking by electric eye, accurate positioning of trademark.

10. Formers can be quickly replaced without tools.

1.Easy to change bag size and bag type.

2.Easy to adjust Printer range.

3.Rotary detergent pouch packing machine optoelectronic system can check bag,material filling and sealing situation to avoid failure.

4.Stable worktable with low noise and long life as the bottom drive system.

5.High bag opening effective and low machine failure rate.

6.Sample wiring arrangement with high quality electronic components

Stand up Premade Ziplock Bag Laundry Detergent Capsule Pods Rotary Pouch Packing Machine

1.6Lhopper, suitable for all kinds of common standard materials, can be used widely;

Laundry packaging machine with multihead combination weigher of weighing type for material detection is available, which can make accurate control of feeding time & material thickness and ensure weighing accuracy.

Our automatic doypack zipper bag 3 in 1 laundry detergent pods filling packing machine is suitable for weighing and filling of various fragile and breakable items, such as laundry pods, detergent capsules, laundry gels, laundry balls, laundry tablets, etc. This detergent filling machine can fill free flowing low weighing engineering products and many more. We can provide customized solutions, whether you need a large or small batch laundry pods capsules production line, our detergent pouch packing machine can meet your needs.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

Yes, if asked, we will supply relevant technical details regarding Smart Weigh. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

In essence, a long-standing non food packing line organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. non food packing line QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

In China, ordinary working time is 40 hours for employees who work full time. In Smart Weigh Packaging Machinery Co., Ltd., most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Packing Machine and an unforgettable experience of partnering with us.

Smart Weigh Packaging Machinery Co., Ltd. always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved