Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Smart Weigh has developed to be a professional manufacturer and reliable supplier of high-quality products. Throughout the whole production process, we strictly implement the ISO quality management system control. Since established, we always adhere to independent innovation, scientific management, and continuous improvement, and provide high-quality services to meet and even exceed customers' requirements. We guarantee our new product grain packaging machine will bring you a lot of benefits. We are always standby to receive your inquiry. grain packaging machine If you are interested in our new product grain packaging machine and others, welcome you to contact us.If you're looking for a brand that prioritizes cleanliness, then Smart Weigh should definitely be on your list. Their production room is strictly maintained to ensure no dust or bacteria are present. In fact, for the inner parts that come into direct contact with your food, there's absolutely no room for contaminants. So if you're health-conscious and want to make sure you're only consuming the best, then choose Smart Weigh.

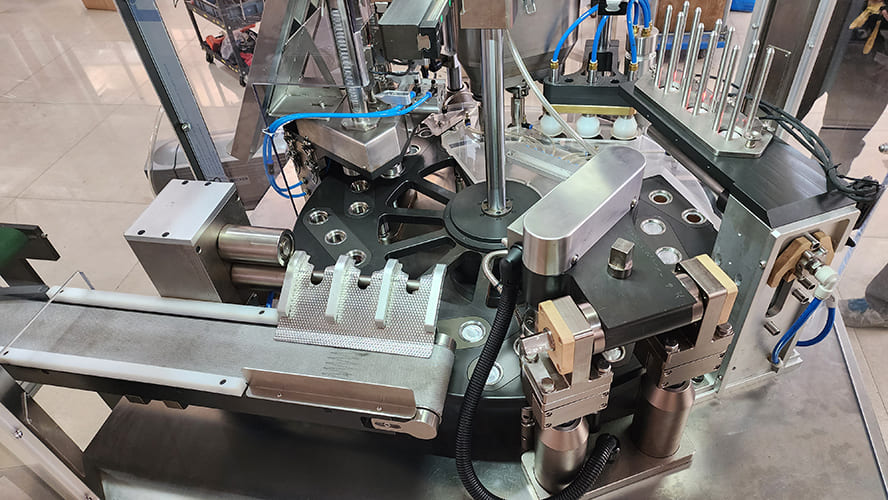

Are you looking for a better coffee pod packaging machine or k cup packaging machines to improve the operational efficiency of your manufacturing facility? Our SW-KC series coffee pod filling and sealing machine brings your search to a conclusion!

This professional coffee capsule filling and sealing machines, engineered specifically for coffee weighing, capsule or k cup filling and sealing. To make high-quality coffee capsules quickly, simply prepare coffee granules or powder, empty capsules, and aluminum foil covers, and follow simple instructions.

The coffee capsule packaging machine's ability to produce 80-200 K cups per minute significantly increases your manufacturing efficiency. The SW-KC series machine has an extensive range of applications. It is intended for use with various powdered and granulated items such as tea, milk powder, and instant mix, in addition to coffee industry. And it can pack products into capsules, k cup, and nespresso.

Lower footprint: Unlike the current market's straight shape, ours is rotational, allowing for a lower footprint while improving performance.

Efficiency: The model emphasizes its efficiency by filling 70-80 coffee capsules per minute for each lane, thus considerably enhancing output efficiency and decreasing operational expenses..

Accuracy: In addition to efficiency, the SW-KC series ensures precision with an innovative auger filling system and control mechanism that precisely manages the weight of each capsule and assures accuracy within 0.2 grams, thereby keeping the coffee capsules' homogeneity and stability.

Ease of operation: Values simplicity in its functioning. Complete the filling and sealing process with a few button presses. The addition of a touchscreen interface and an error prompt feature allows for constant monitoring and modifications to the operational state.

Hygiene: The coffee capsule filling sealing machine is made of stainless steel and has a sealing design that prevents dust and bacterial contamination, ensuring the hygiene and security of the coffee capsules.

| Model | SW-KC01 | SW-KC03 |

| Capacity | 80 Fills/minute | 210 Fills/minute |

| Container | K cup/capsule | |

| Filling Weight | 12 grams | 4-8 grams |

| Accuracy | ±0.2g | ±0.2g |

| Voltage | 220V, 50/60HZ, 3 phase | |

| Machine Size | L1.8 x W1.3 x H2 meters | L1.8 x W1.6 x H2.6 meters |

Finally, if you want to improve the operational efficiency of your manufacturing setup with an advanced coffee pod packaging or K cup packing equipment, Smart Weigh's SW-KC series coffee pod filling and sealing machine is the appropriate answer.

The SW-KC series, designed exclusively for optimizing coffee capsule manufacturing, is equipped with an innovative auger filling technology to assure precision, as well as a sanitary stainless steel structure that ensures complete sanitation and safety of the coffee capsule.

Our machine's adaptability extends beyond coffee and allows it to accommodate a number of powdered and granulated substances such as tea, milk powder, and instant mix, making it a comprehensive solution for a wide range of packaging needs.

Despite its space-saving small design, the machine maintains high performance. It prioritizes cost-effective operation, providing a spectacular filling speed of 70-80 coffee capsules per minute per lane, as well as a sophisticated touch-screen control that simplifies the operation procedure.

Let Smart Weigh's SW-KC series coffee capsule filling and sealing machine improve your manufacturing process with its unsurpassed efficiency, pinpoint accuracy, and high hygiene standards. With our SW-KC series equipment, you can increase productivity and profitability in the coffee capsule packing industry. With Smart Weigh, you can easily navigate towards premium coffee experiences with a single button click.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. grain packaging machine QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

In essence, a long-standing grain packaging machine organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

In China, ordinary working time is 40 hours for employees who work full time. In Smart Weigh Packaging Machinery Co., Ltd., most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Packing Line and an unforgettable experience of partnering with us.

Smart Weigh Packaging Machinery Co., Ltd. always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

The buyers of grain packaging machine come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved