Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Guided by scientific and technological innovation, Smart Weigh always keeps outward-oriented and sticks to the positive development on the basis of technological innovation. multihead weighing machines Smart Weigh have a group of service professionals who are responsible for answering questions raised by customers through the Internet or phone, tracking the logistics status, and helping customers solve any problem. Whether you'd like to get more info on what, why and how we do, try our new product - Good Selling multihead weighing machines suppliers, or would like to partner up, we'd love to hear from you.The materials used in Smart Weigh is up to the food grade requirement. The materials are sourced from suppliers who all hold food safety certifications in dehydrating equipment industry.

Multihead weighers are super versatile and used in all sorts of industries, especially where you need to be really exact with how much product goes into each package. 10 head multihead weigher, is typical and standard model, is really handy in a bunch of different industries for weighing stuff accurately and quickly.

It is mainly apply in automatic weighing various granular products in food or non-food industries, such as snack foods, potato chips, nuts, dried fruits, beans, frozen foods, vegetable, sea food, hardware and etc.

10 head weighers are often integrated into packaging systems for efficient and automated packaging processes.

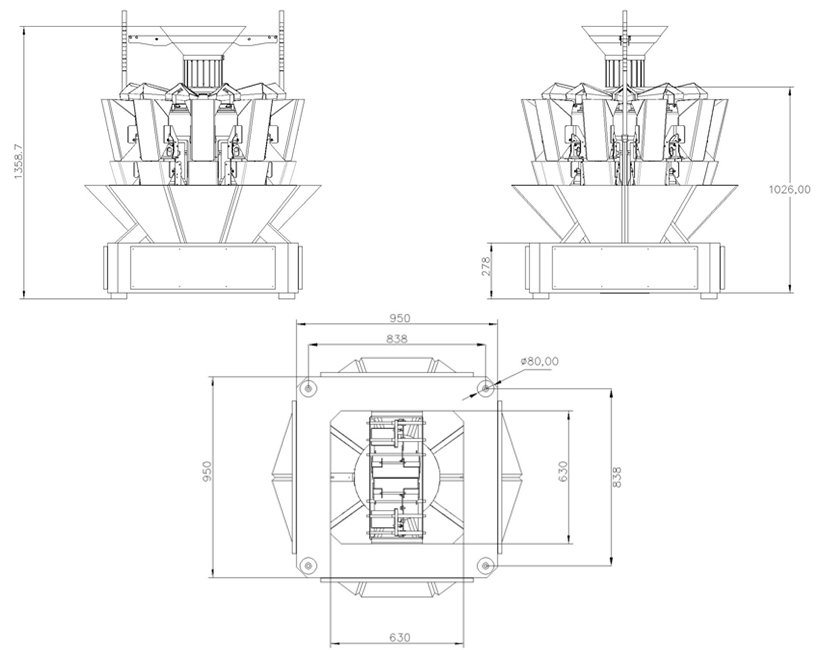

Model | SW-M10 |

Weighing Range | 10-1000 grams |

Max. Speed | 65 bags/min |

Accuracy | + 0.1-1.5 grams |

Hopper Volume | 1.6L or 2.5L |

Control Penal | 7" Touch Screen |

Power Supply | 220V/50HZ or 60HZ; 10A; 1000W |

Driving System | Stepper Motor |

Packing Dimension | 1620L*1100W*1100H mm |

Gross Weight | 450 kg |

The weighers can be customized with different surfaces, vibrating plate angle and settings to cater to specific industry needs and product types.

◇ IP65 waterproof, use water cleaning directly, save time while cleaning;

◆ Modular control system, more stability and lower maintenance fees;

◇ Production records can be checked at anytime or download to PC;

◆ Load cell or photo sensor checking to satisfy different requirements;

◇ Preset stagger dump function to stop blockage;

◆ Design linear feeder pan deeply to stop small granule products leaking out;

◇ Refer to product features, select automatic or manual adjust feeding amplitude;

◆ Food contact parts disassembling without tools, which is easier to clean;

◇ Multi-languages touch screen for various clients, English, French, Spanish, etc;

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved