Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Over the years, Smart Weigh has been offering customers high-quality products and efficient after-sales services with the aim of bringing unlimited benefits for them. vertical form filling machine We will do our best to serve customers throughout the whole process from product design, R&D, to delivery. Welcome to contact us for further information about our new product vertical form filling machine or our company.Smart Weigh is developed creatively by the R&D team. It is created with dehydrating parts including heating element, a fan, and air vents which are essential in the air circulating.

The nuts packaging machine not only used to pack all kinds of nut products and dried fruits, but also puffed food, chips, cereals, chocolate, cookies, candy, shrimp sticks and other snacks.

Material

bag type

bag type

Cashew almond nut packaging machine

Also suitable to pack sunflower seeds, potato chip, puffed food, jelly, pet food, snack, gummy, dried fruit, coffee bean, sugar, salt, etc

*

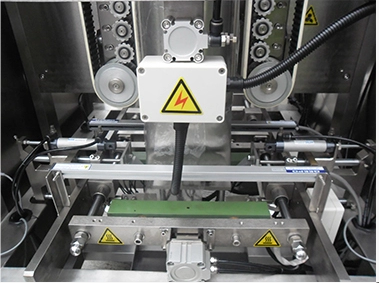

* Semi -automatic film rectifying deviation function;

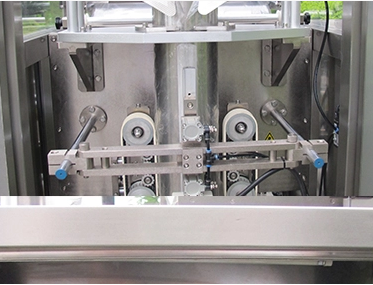

* Famous brand PLC. Pneumatic system for vertical and horizontal sealing;

* Compatible with different internal and external measuring device;

* Suitable to packing granule, powder, strip shape materials, such as puffed food, shrimp, macadamia nuts, peanuts, popcorn, sugar, salt, seeds, etc.

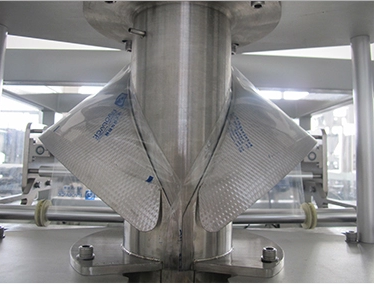

* The way of bag making: the machine can make different types bag from the film roll, such as pillow-type bag, gusset bag and standing-bevel quad bag according to customer’s requirements.

Model | SW-PL1 |

Weighing Range | 10-5000 grams |

Bag Style | Pillow bag, gusset bag, four side seal bag |

Bag Size | Length: 120-400mm Width: 120-350 mm |

Bag Material | Laminated film, Mono PE film |

Film Thickness | 0.04-0.09 mm |

Max. Speed | 20-50 bags per minute |

Accuracy | ±0.1-1.5 grams |

Weigh Bucket | 1.6L or 2.5 L |

Control Penal | 7" or 9.7 " Touch Screen |

Air Consumption | 0.8 Mps, 0.4m3/min |

Driving System | Step motor for scale, servo motor for packing machine |

Power Supply | 220V/50 Hz or 60 Hz, 18A, 3500 W |

By noticing this, can you just find the difference with newly updated ones.

Here also no cover for powder packing, not that good for protect from dust pollution.

Smart Weight provides you with an ideal weighing and packaging solution. Our weighing machine can weigh particles, powders, flowing liquids and viscous liquids. The specially designed weighing machine can solve the weighing challenges. For example, the multi head weigher with dimple plate or Teflon coating is suitable for viscous and oily materials, the 24 head multi head weigher is suitable for mixture flavor snacks, and the 16 head stick shape multi head weigher can solve the weighing of stick shape materials and bags in bags products. Our packaging machine adopts different sealing methods and is suitable for different bag types. For example, vertical packaging machine is applicable to pillow bags, gusset bags, four side seal bags, etc., and the premade bag packaging machine is applicable to zipper bags, stand up pouches, doypack bags, flat bags, etc. Smart Weigh can also plan the weighing and packaging system solution for you according to the actual production situation of customers, so as to achieve the effect of high precision weighing, high efficiency packing and space saving.

How does the customer check the quality of the machine?

Before delivery, Smart Weight will send you photos and videos of the machine. More importantly, we welcome customers to check the operation of the machine on site.

How does Smart Weight meet customer requirements and demands?

We provide customized services for you, and answer customers' questions online 24 hours at the same time.

What is the payment method?

Direct telegraphic transfer through bank account

Sight letter of credit

Regarding the attributes and functionality of the vertical form filling machine, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

In essence, a long-standing vertical form filling machine organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

In China, ordinary working time is 40 hours for employees who work full time. In Smart Weigh Packaging Machinery Co., Ltd., most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Inspection Machine and an unforgettable experience of partnering with us.

Smart Weigh Packaging Machinery Co., Ltd. always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

The buyers of vertical form filling machine come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved