Guided by scientific and technological innovation, Smart Weigh always keeps outward-oriented and sticks to the positive development on the basis of technological innovation. automated packaging machine We promise that we provide every customer with high-quality products including automated packaging machine and comprehensive services. If you want to know more details, we are glad to tell you. Actively learn foreign advanced equipment and manufacturing technology, continuously improve and upgrade products, strive to improve the internal performance and external quality of products, and ensure that automated packaging machine manufactured are high-quality products with high technological content, safe and reliable quality .

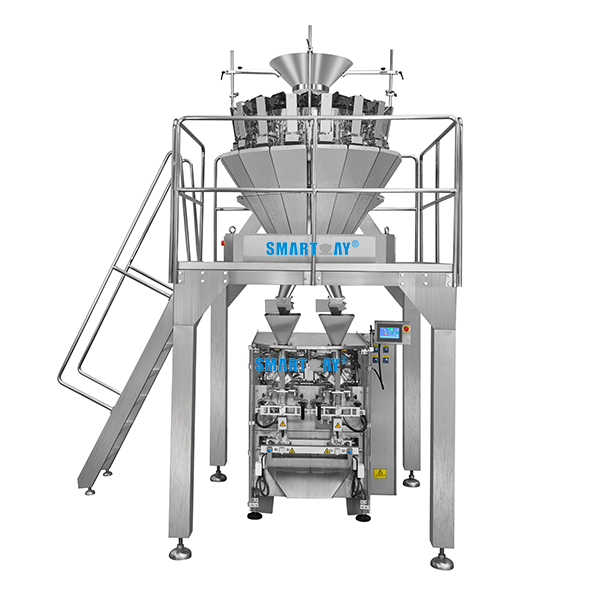

Take your snack packaging to the next level with Smart Weigh's cutting-edge Kanelbulle Bag Packing Machine. We specialize in crafting customized solutions designed to meet the unique demands of our clients. Engineered for excellence, this machine seamlessly integrates a multihead weigher with a vertical packing system, ensuring precision, efficiency, and consistent reliability while creating eye-catching pillow bags for your Kanelbulle (Cinnamon Bun).

With 12 years of expertise, Smart Weigh delivers innovative, tailored packaging solutions designed to meet diverse production needs. From semi-automatic to fully automated systems, our machines combine advanced technology with scalable options to fit any budget. Supported by a global network, we offer seamless installation, training, and ongoing assistance to ensure peak performance and minimal downtime.

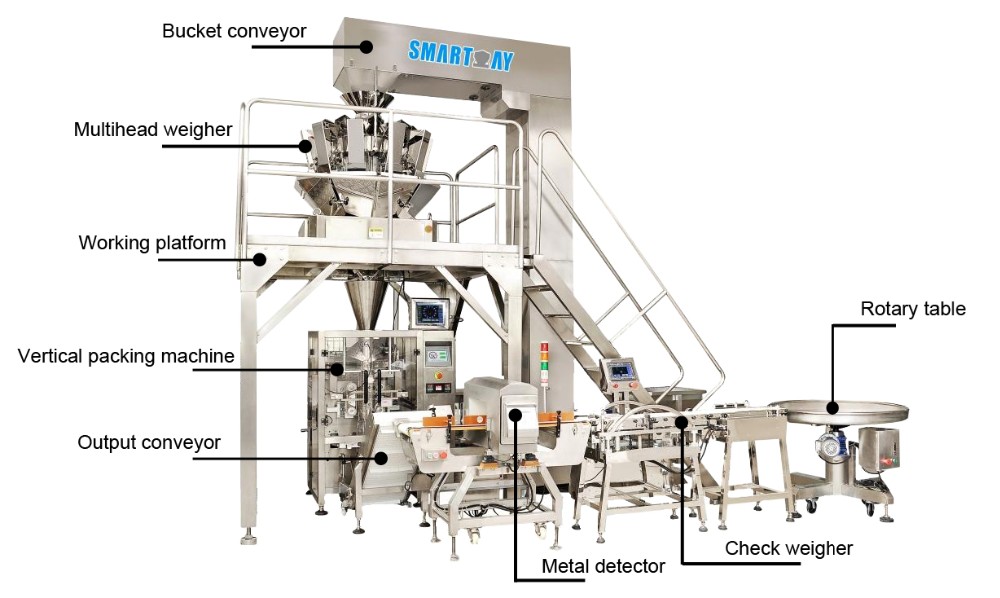

What are the components of Kanelbulle Packaging Machine?

bg

1. Feed Conveyor: bucket conveyor or incline conveyor for choices, auto feed the pretezel to weighing machine.

2. 14 Head Multihead Weigher: the popular used model for high speed and weighing precision

3. Vertical packing machine: auto form pillow or gusset bags from the roll film, seal the bags with Kanelbulle

4. Output conveyor: deliver the finished bags to next equipment

5. Rotary collect table: collect the finished bags for next packaging steps

Optional Add-ons

1. Date Coding Printer

Thermal Transfer Overprinter (TTO): Prints high-resolution text, logos, and barcodes.

Inkjet Printer: Suitable for variable data printing directly on packaging films.

2. Nitrogen Flushing System

Modified Atmosphere Packaging (MAP): Replaces oxygen with nitrogen to inhibit oxidation and microbial growth.

Freshness Preservation: Ideal for extending the shelf life of perishable snack products.

3. Metal Detector

Integrated Detection: Inline metal detection to identify ferrous and non-ferrous metal contaminants.

Automatic Rejection Mechanism: Ensures contaminated packages are removed without halting production.

4. Check Weigher

Post-Packaging Verification: Weighs finished packages to ensure compliance with weight specifications.

Data Logging: Records weight data for quality control and regulatory compliance.

5. Secondary Wrapping Machine

Technical Specifications

bg

| Weighing Range | 10 grams to 500 grams |

|---|

| Number of Weighing Heads | 14 head |

| Packing Speed | Up to 60 bags per minute (variable based on product characteristics and bag size) |

| Bag Style | Pillow bag, gusset bag |

| Bag Size Range | Width: 60 mm - 250 mm Length: 80 mm – 350 mm |

| Film Thickness | 0.04 mm - 0.09 mm |

| Power Supply | 220 V, 50/60 Hz, 3 kW |

| Air Consumption | 0.6 m³/min at 0.6 MPa |

| Control System | Multihead weigher: modular board control system with 7-inch touch screen Packing machine: PLC with 7-inch color touch-screen interface |

| Language Support | Multilingual (English, Spanish, Chinese, Korea, etc.) |

bg

Multihead Weigher for Precision Weighing

Our multihead weigher is engineered for exceptional accuracy and speed:

High-Precision Load Cells: Each head is equipped with sensitive load cells to ensure precise weight measurements, reducing product giveaway.

Flexible Weighing Options: Adjustable parameters to accommodate various Kanelbulle sizes and shapes.

Optimized Speed: Efficiently handles high-speed operations without compromising on accuracy, enhancing productivity.

Vertical Packing Machine for precision cutting

The vertical packing machine forms the core of the packaging system:

Pillow Bag Formation: Crafts visually appealing pillow bags that enhance product presentation and brand image.

Advanced Sealing Technology: Utilizes heat-sealing mechanisms to ensure airtight packaging, preserving freshness and extending shelf life.

Versatile Bag Sizes: Easily adjustable to produce different bag widths and lengths, catering to diverse market demands.

High-Speed Operation

Integrated System Design: Synchronization between the multihead weigher and packing machine enables smooth and rapid packaging cycles.

Enhanced Throughput: Capable of packaging up to 60 bags per minute, depending on product characteristics and packaging specifications.

Continuous Operation: Designed for 24/7 operation with minimal maintenance interruptions.

Gentle Product Handling

Minimal Drop Height: Reduces the distance Kanelbulle fall during packaging, minimizing breakage and maintaining product integrity.

Controlled Feeding Mechanism: Ensures a steady flow of Kanelbulle into the weighing system without clogging or spillage.

User-Friendly Interface

Touch-Screen Control Panel: Intuitive interface with easy navigation, allowing operators to monitor and adjust settings effortlessly.

Programmable Settings: Save multiple product parameters for quick changeovers between different packaging requirements.

Real-Time Monitoring: Displays operational data such as production speed, total output, and system diagnostics.

Durable Stainless Steel Construction

SUS304 Stainless Steel: Crafted with high-quality, food-grade stainless steel for durability and compliance with hygiene standards.

Robust Build Quality: Designed to withstand rigorous industrial environments, reducing long-term maintenance costs.

Easy Maintenance and Cleaning

Hygienic Design: Smooth surfaces and rounded edges prevent residue buildup, facilitating quick and thorough cleaning.

Tool-Free Disassembly: Key components can be disassembled without tools, streamlining maintenance procedures.

Compliance with Food Safety Standards

Certifications: Meets international standards such as CE, ensuring compliance and facilitating global market access.

Quality Control: Rigorous testing protocols ensure each machine meets our strict quality benchmarks before delivery.

The Smart Weigh Kanelbulle Packing Machine is ideal for packaging:

Baked Snacks

chips

Breadsticks

Crackers

Mini pastries

Confectioneries

Candies

Chocolate bites

Gummies

Nuts and Dried Fruits

Almonds

Peanuts

Cashews

Raisins

Other Granular Products

Cereals

Seeds

Coffee beans

Offer Different Automation Grades Kanelbulle Packing Solutions

bg

1. Semi-Automatic Solutions

Ideal for Small Businesses: Enhances efficiency while allowing for manual oversight.

Features:

Manual product feeding

Automated weighing and packaging

Basic control interface

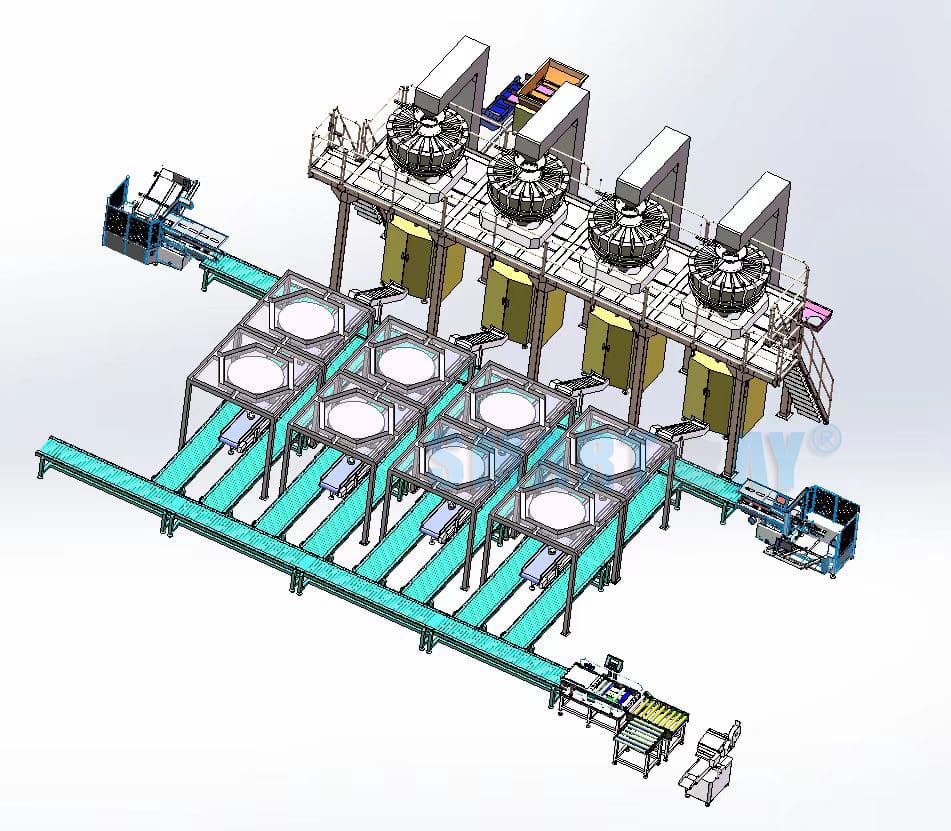

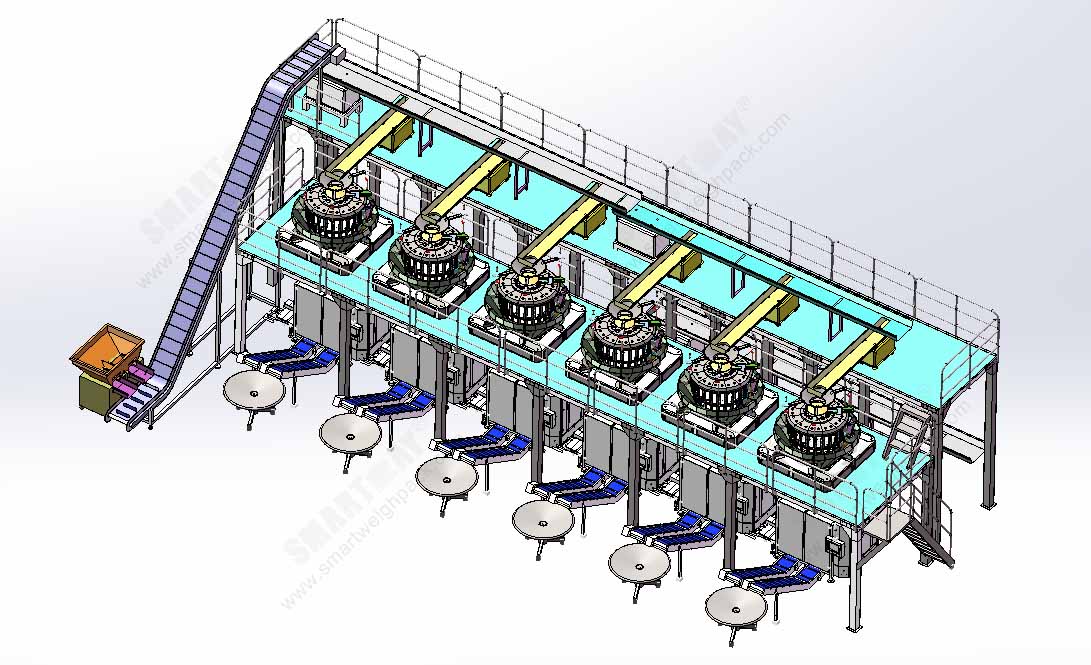

2. Fully Automatic Systems

Designed for High-Volume Production: Minimizes human intervention for consistent, high-speed operation.

Features:

Automatic product feeding via conveyors or elevators

Integrated optional add-ons

Customized Configurations for Secondary Wrapping Machine and Palletizing System

100 packs/min Solution

high speed 24 head with twin

former vffs

Fully Automatic Solution

Including auto cartoning

1. Comprehensive Support

Consultation Services: Expert advice on selecting the right equipment and configurations.

Installation and Commissioning: Professional setup to ensure optimal performance from day one.

Operator Training: In-depth training programs for your team on machine operation and maintenance.

2. Quality Assurance

Stringent Testing Procedures: Each machine undergoes thorough testing to meet our high-quality standards.

Warranty Coverage: We offer warranties that cover parts and labor, providing peace of mind.

3. Competitive Pricing

Transparent Pricing Models: No hidden costs, with detailed quotations provided upfront.

Financing Options: Flexible payment terms and financing plans to accommodate budgetary constraints.

4. Innovation and Development

Research-Driven Solutions: Continuous investment in R&D to introduce cutting-edge features and enhancements.

Customer-Centric Approach: We listen to your feedback to improve our products and services continually.

Ready to take your snack packaging to the next level? Contact Smart Weigh today for a personalized consultation. Our team of experts is eager to help you find the perfect packaging solution tailored to your business needs.