Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost.

Why do certain factories pack more quickly? How can I increase packing efficiency?

The customer is a Greek producer of packaged snacks, primarily of cookies, potato chips, shrimp sticks, chocolate, and other puffed food. He previously employed the labor-intensive and inefficient manual packaging approach. Now, in order to achieve fully automatic weighing and packaging, he uses the twin vertical packing machine with multihead weigher that Smart Weigh has recommended.

Double bagger vertical form fill seal packaging machine works efficiently, takes up little room, is appropriate for small scale workshops, and more affordable than packaging machine for premade pouch.

Twin lanes VFFS duplex type packing machine can wrap two products at once to accommodate the more flexible needs of customers, and it can produce 120 bags per minute ( 120 x 60 minutes x 8 hours = 57600 bags/day), which makes it easier to increase output.

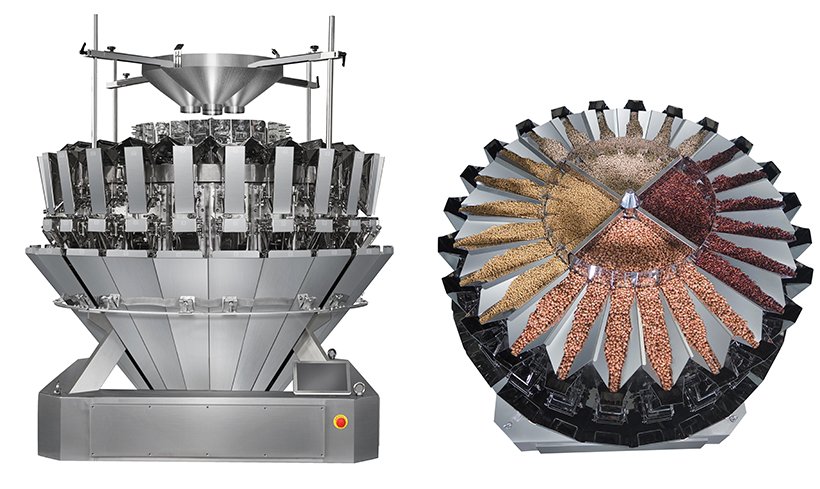

Name | Twin machine with 24 heads weigher |

Capacity | 120 bags/min according to the bag sizes it is also affected by the quality of film and bag length |

Accuracy | ≤±1.5% |

Bag size | (L)50-330mm (W)50-200mm |

Film width | 120 - 420mm |

Bag type | Pillow bag( optional: gusseted bag, strip bag, bags with euro slot) |

Pulling belt type | Double-belts pulling film |

Filling range | ≤ 2.4L |

Film thickness | 0.04-0.09mm the best is 0.07-0.08 mm |

Film material | thermal composite material., like BOPP/CPP, PET/AL/PE etc. |

Size | L4.85m * W4.2m * H4.4m ( for one system only) |

1. Multipurpose, highly effective packaging machine that can handle the entire filling, sealing, cutting, heating, bag-making, and coding operation.

2. An easy-to-use color touch screen allows you to choose the bag length and packing speed.

3. A self-contained temperature controller with a heat balance feature that can accommodate various packing materials.

4. An automatic stop mechanism to save rolled film and ensure operation safety.

5. Weighing precision of 0.1-1.5 g.

name | function |

Z type conveyor | vertical elevating granules |

Vibratory Feeder | feeding bulk materials |

accurate and reliable weighing | |

Platform | support the weigher |

filling, sealing and packing | |

Output conveyor | conveying finished products |

It is an ideal option for foods packaged in pillow bags, sachets or linked bags.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425