Kusukela ngo-2012 - i-Smart Weight izibophezele ekusizeni amakhasimende ukwandisa umkhiqizo ngezindleko eziphansi.

Uyini Umehluko Phakathi Kokupakisha Okuyimpuphu Nomshini Wokupakisha I-Granule?

Uma ufuna ukuqonda umehluko phakathi komshini wokupakisha we-powder kanye ne-granule, khona-ke ufike endaweni efanele. Nokho, ukukhetha isethi efanele yemishini kubaluleke kakhulu emabhizinisini. Imishini kuphela ingenza umehluko omkhulu phakathi komkhiqizo wekhwalithi enhle kanye nomubi. Ngaphezu kwalokho, ingathinta nokukhiqiza kokusebenza. Kulesi sihloko, sizoxoxa ngomshini wokupakisha we-powder kanye nomshini wokupakisha we-granule, kanye nomehluko phakathi kwezinhlobo ezimbili zemishini.

Uyini Umshini Wokupakisha Ufulawa?

Ukupakishwa okuhle komkhiqizo kudinga imishini ekhethekile. Nokho, umshini wokupakisha impuphu wenzelwe ngqo ukupakisha impuphu ezincane, ezomile, nezinye ezilula. Ngomshini onjalo, ungapakisha impuphu ezitsheni ezahlukene - njengezikhwama namabhodlela. Usebenzisa umshini okhethekile, ungaqinisekisa ukuthi impuphu zigcwaliswa njalo ngokunemba. Ngaphezu kwalokho, ungawuvala umkhiqizo ngokuphephile ukuze ugweme noma yikuphi ukungcola kanye nokumosheka.

Izimboni Ezifanele kanye Nezinhlobo Zempuphu Ephathwayo

Izimboni eziningana zisebenzisa umshini wokufaka izikhwama zempuphu. Isibonelo - ukudla, imithi, kanye namakhemikhali kuvame ukutholakala kusetshenziswa uhlobo lomshini olunjalo. Esigabeni sokudla, imishini ingapakisha ufulawa, izinongo, ubisi oluyimpuphu, kanye nempuphu yamaprotheni. Amabhizinisi emkhakheni wezokwelapha asebenzisa umshini ukupakisha impuphu yezokwelapha kanye nezithasiselo zokudla. Imboni yamakhemikhali, kuyilapho, isebenzisa umshini ukugcwalisa insipho kanye nomanyolo, phakathi kwezinye izinto.

Izinhlobo Zemishini Yokupakisha Impuphu

✔ 1. Umshini Wokupakisha Isikhwama Sempuphu one-Auger Filler

Lo mshini ungapakisha ngokushesha nangokuzenzakalela uhla olubanzi lwezimpushana okuhlanganisa i-chili powder, i-coffee powder, i-milk powder, i-matcha powder, i-soybean powder, kanye nofulawa kakolweni. Umshini wokugcwalisa isikhwama sempushana one-auger filler kanye ne-screw feeder. Umklamo ovaliwe ungagwema ngempumelelo ukuvuza kwempushana futhi unciphise ukungcola kothuli.

▲ Izici Eziyinhloko:

● I-Auger Filler kanye ne-Screw Feeder: Enhliziyweni yalo mshini kukhona i-auger filler, indlela enembile elinganisa futhi ikhiphe inani eliqondile lempuphu esikhwameni ngasinye. Uma ihlanganiswe ne-screw feeder, iqinisekisa ukugeleza okuqhubekayo nokungaguquguquki kwempuphu kusuka ku-hopper kuya esiteshini sokugcwalisa, kunciphisa ukungalingani kanye nokuthuthukisa ukusebenza kahle.

● Umklamo Ovaliwe: Esinye sezici ezivelele zalo mshini isakhiwo sawo esivalekile ngokuphelele. Lo mklamo uvimbela ngempumelelo ukuvuza kwempuphu ngesikhathi sokusebenza, unciphisa imfucuza yomkhiqizo. Ngaphezu kwalokho, kunciphisa kakhulu ukungcola kothuli, kudala indawo yokusebenza ehlanzekile nephephile kubasebenzi—inzuzo ebalulekile ezimbonini ezifana nokucubungula ukudla noma imithi lapho inhlanzeko ibaluleke kakhulu khona.

● Isivinini Esiphezulu Nokuzenzakalela: Lo mshini wenzelwe ukupakisha okusheshayo, okwenza kube ukukhetha okuhle kakhulu kwemigqa yokukhiqiza enomthamo omkhulu. Uhlelo lwawo oluzenzakalelayo oluphelele lwenza inqubo ibe lula kusukela ekukhipheni i-powder kuya ekuvaleni izikhwama, kunciphisa isidingo somsebenzi wezandla futhi kukhuphule umkhiqizo jikelele.

✔ 2. Umshini Wokupakisha Oqondile We-Powder one-Screw Conveyor

Umshini wokupakisha i-powder yekhofi eqondile ulungele ukupakisha impuphu ehlukahlukene okuhlanganisa ufulawa, ufulawa wombila, ikhofi, kanye nempuphu yezithelo. Ijubane lalo mshini lilungiswa ngokuguqulwa kwemvamisa ngebanga, futhi ijubane langempela lincike kuhlobo lwemikhiqizo kanye nesikhwama.

▲ Izici Eziyinhloko:

● I-Screw Conveyor: Lo mshini une-screw conveyor ethutha kahle i-powder kusuka endaweni yokugcina izinto iye esiteshini sokugcwalisa. I-conveyor iqinisekisa ukugeleza okulawulwayo nokungaguquguquki, okwenza kube ngcono kakhulu kuma-powder amahle, ageleza ngokukhululeka, noma ayinselele angase avale noma ahlale ngokungalingani.

● Isivinini Esilungisekayo Ngokuguqulwa Kwemvamisa: Isivinini sokupakisha salo mshini singenziwa ngokwezifiso kusetshenziswa ubuchwepheshe bokuguqulwa kwemvamisa. Lokhu kuvumela opharetha ukuthi balungise isivinini ngaphakathi kobubanzi obuthile, basenze sivumelane nezidingo zomugqa wokukhiqiza. Isivinini sangempela esifinyelelwayo sincike ezicini ezifana nohlobo lwempuphu epakishwayo (isb., ubuningi bayo noma ukugeleza kwayo) kanye nezinto zesikhwama (isb., ipulasitiki, ifilimu elaminethiwe), enikeza ukuguquguquka kokusebenza.

● Umklamo Oqondile: Njengomshini wokupakisha oqondile, wakha izikhwama ezivela kumqulu wefilimu, uzigcwalise ngempuphu, bese uzivala ngenqubo eqhubekayo. Lo mklamo usebenza kahle endaweni futhi ulungele kahle izindawo ezisebenzisa amandla amaningi.

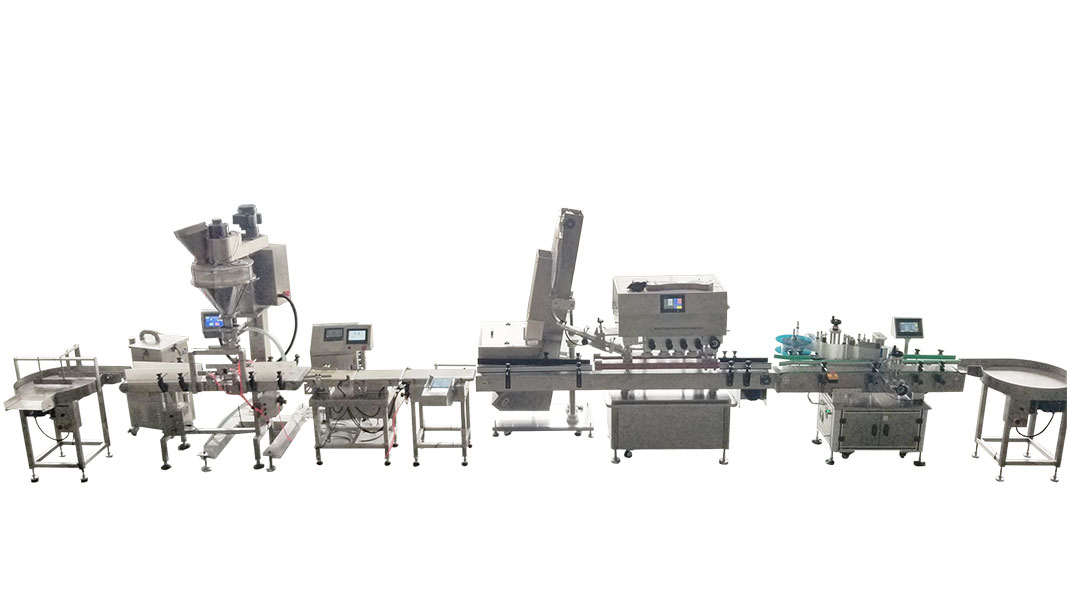

✔ 3. Umshini Wokupakisha Wokugcwalisa Ibhodlela Lempuphu

Lo mshini wokupakisha ulungele kangcono izinhlobo ezahlukene zamathini njengepulasitiki, i-tinplate, iphepha, kanye ne-aluminium. Amabhizinisi kuyo yonke imboni - njengokudla kanye nemithi - asebenzisa lo mshini wokupakisha.

▲ Izici Eziyinhloko:

● Ukuguquguquka Ezinhlotsheni Zezitsha: Ikhono lalo mshini lokwamukela izinto ezahlukene zezitsha nobukhulu likwenza kube lula ukuzivumelanisa nezimo. Kungakhathaliseki ukuthi ibhizinisi lisebenzisa amabhodlela amancane epulasitiki ukuze lenze izinongo noma amathini amakhulu e-aluminium ukuze lenze impuphu yokudla okunempilo, lo mshini ungawenza lo msebenzi, unciphise isidingo semishini eminingi ekhethekile.

● Ukugcwalisa Ngokunembile: Umshini uhlonyiswe ngezindlela zokuqinisekisa ukugcwaliswa okunembile kwama-powder esitsheni ngasinye. Lokhu kunemba kunciphisa ukugcwalisa ngokweqile noma ukugcwalisa okungaphansi, kuqinisekisa isisindo somkhiqizo esiqhubekayo kanye nokunciphisa imfucuza yezinto—okuyinto ebalulekile okufanele icatshangelwe ekusebenzeni okuqaphela izindleko.

● Izicelo Ezibanzi Zemboni: Isetshenziswa kabanzi emikhakheni eyahlukene, okuhlanganisa:

▶ Imboni Yokudla: Yezimpushana zokupakisha njengezinongo, izingxube zokubhaka, izimpushana zamaprotheni, kanye nezingxube zeziphuzo ezisheshayo.

▶ Imboni Yezemithi: Yokugcwalisa imithi eyimpuphu, amavithamini, noma izithasiselo zezempilo emabhodleleni noma emathini, lapho ukunemba kanye nenhlanzeko kubalulekile khona.

Uyini Umshini Wokupakisha I-Granule?

Umshini wokupakisha we-Granule wenzelwe ngqo ukuphatha imikhiqizo enesakhiwo se-granular. Lokhu kungafaka okusanhlamvu okuncane nama-pellet amakhulu. Ukusetshenziswa kwalo mshini kuqinisekisa ukuthi imikhiqizo ipakishwa ngokunemba nangokusebenza kahle. Lokhu kuqinisekisa ukuthuthwa okulula futhi kuthuthukise ikhwalithi.

Izimboni Ezifanele kanye Nezinhlobo Zama-granule Aphathwayo

Amabhizinisi emikhakheni efana nokudla, ezolimo, kanye nokwakha atholakala esebenzisa umshini wokugcwalisa ama-granule. Nokho, usetshenziselwa ukupakisha ushukela, ilayisi, okusanhlamvu, nezinye izinto zokudla. Emkhakheni wezolimo, umshini ungasetshenziswa ukupakisha umanyolo, imbewu, kanye nokudla kwezilwane. Kanti, embonini yokwakha, umshini ungapakisha izinto zokwakha okuhlanganisa isihlabathi kanye notshani.

Izinhlobo Zemishini Yokupakisha I-Granule

▶ 1. Umshini Wokupakisha Isikhwama Esinamakhanda Amaningi Ozenzakalelayo

Umshini wokupakisha isikhwama sokulinganisa isisindo esinezinhloko eziningi uwuhlelo olukhethekile olwenzelwe ukugcwalisa nokuvala izikhwama ezakhiwe ngaphambilini ngenani eliqondile lomkhiqizo. Enhliziyweni yawo kukhona umshini wokulinganisa isisindo onezinhloko eziningi, umshini ohlonyiswe ngamakhanda amaningi okulinganisa isisindo (noma ama-hopper) asebenza ndawonye ukulinganisa nokukhipha imikhiqizo ngokunembile. Nansi indlela osebenza ngayo:

● Inqubo Yokukala: Umkhiqizo usatshalaliswa kuma-hopper amaningana okulinganisa isisindo, ngalinye lilinganisa ingxenye yesisindo sonke. Isofthiwe yomshini ibala inhlanganisela yama-hopper afanelana kakhulu nesisindo esiqondiwe bese ikhipha lelo nani.

● Ukugcwalisa Nokuvala: Umkhiqizo olinganiswe kahle ube usufakwa esikhwameni esenziwe ngaphambilini. Umshini wokupakisha isikhwama ugcwalisa isikhwama bese usivala, ngokuvamile usebenzisa ukushisa noma ezinye izindlela zokuvala, ukuze kudalwe iphakethe eliqediwe.

▼ Izicelo: Lokhu kusethwa kulungele imikhiqizo edinga ukupakishwa ngobuningi obuthile, njenge:

◇ Ukudla okulula (isib. ama-chips, amantongomane)

◇ Ukudla kwezilwane ezifuywayo

◇ Ukudla okuqandisiwe

◇I-confectionery (isib. amaswidi, ushokoledi)

▲ Izici Eziyinhloko:

● Amaphakethe angenziwa ngokwezifiso ngobukhulu, ukuma, kanye nezinto zokwakha (isib. ipulasitiki, i-foil).

● Kuqinisekisa ukuhambisana futhi kunciphisa imfucuza yomkhiqizo ngokunciphisa ukugcwalisa ngokweqile.

▶ 2. Umshini Wokupakisha Oqondile Onamakhanda Amaningi

Umshini wokupakisha oqondile onezisindo eziningi, owaziwa kakhulu ngokuthi umshini wokugcwalisa ifomu eliqondile (VFFS), usebenzisa indlela ehlukile ngokudala izikhwama ngomqulu oqhubekayo wefilimu. Uhlanganiswe nesisindisi esinezisindo eziningi, unikeza inqubo yokupakisha engenamthungo nesheshayo. Nansi indlela osebenza ngayo:

● Ukwakheka Kwesikhwama: Umshini udonsa umqulu wefilimu eyisicaba, uwubumbe ube yipayipi, bese uvala imiphetho ukuze wakhe isikhwama.

● Inqubo Yokukala: Njengomshini wokupakisha isikhwama, isikali samakhanda amaningi silinganisa umkhiqizo sisebenzisa ama-hopper amaningi bese sikhipha inani eliqondile esikhwameni esisha.

● Ukugcwalisa Nokuvala: Umkhiqizo uwela esikhwameni, bese umshini uvala ingxenye ephezulu ngenkathi uwusika emqulwini wefilimu, uqedela iphakheji ngokusebenza okukodwa okuqhubekayo.

▼ Izicelo: Lolu hlelo luhamba phambili ekupakisheni imikhiqizo ehlukahlukene, okuhlanganisa:

● Ama-granule (isb., ilayisi, imbewu, ikhofi)

●Izinto ezincane zehadiwe (isib. izikulufo, amantongomane)

● Ukudla okulula kanye neminye imikhiqizo egeleza kalula

▲ Izici Eziyinhloko:

●Ukusebenza ngesivinini esikhulu kwenza ifaneleke ekukhiqizweni okukhulu.

● Usayizi nezitayela zezikhwama eziguquguqukayo zingakhiqizwa ngokulungisa ifilimu nezilungiselelo.

Umehluko Obalulekile Phakathi Kwemishini Yokupakisha I-Powder Ne-Granule

Ungaziphambanisi. Zombili lezi zinhlobo zemishini zenzelwe ukupakisha imikhiqizo ngokunemba nangokusebenza kahle. Kodwa-ke, kukhona umehluko phakathi kwemishini yokugcwalisa i-powder kanye ne-granule.

◆ 1. Ukuphathwa Komkhiqizo

Umshini wokupakisha i-powder uklanyelwe ngqo ngezici zokuvimbela ukukhiqizwa kothuli kanye ne-free powders. Kanti, umshini wokupakisha i-granule uklanyelwe ukuphatha imikhiqizo egeleza ngokukhululeka.

◆ 2. Amasu Okuvala

Emshinini wokupakisha i-powder, indlela yokuvala iklanyelwe ukugwema ukubamba i-powder ecolekile endaweni yokuvala. Ngokuvamile kuhlanganisa ukukhipha uthuli noma ukuvala okungenamoya ukuze kugwenywe ukulahleka komkhiqizo.

◆ 3. Indlela Yokufaka Amafayela

Ukuze kulawulwe ukugeleza kwezinhlayiya ezincane, umshini wokufaka izikhwama zempuphu usebenzisa ama-auger fillers. Ngakolunye uhlangothi, imishini ye-granule isebenzisa izinhlelo zokulinganisa ukulinganisa nokukhipha imikhiqizo.

Ungayikhetha Kanjani Imishini Efanele Izidingo Zakho?

Ukutshala imali emishinini yezimboni akuyona nje inqubo ebizayo, kodwa kungaba yinto eyenzeka kanye kuphela emabhizinisini amaningi. Ngakho-ke, ukwenza utshalomali olufanele kuba yinto ebaluleke kakhulu. Nokho, ukuze ukhethe umshini ofanele, kubalulekile ukuthi ube nolwazi olufanele lwemikhiqizo kanye nezici zayo. Nasi uhlu oluzokusiza ukuthi ukhethe umshini ofanele ngokusekelwe ezidingweni zakho.

◇ 1. Nquma ukuthi umkhiqizo wakho ungowempuphu ecolekile noma uhlobo lwe-granule bese ukhetha uhlobo oludingekayo.

◇ 2. Uma udinga izinga eliphezulu lokukhiqiza khetha uhlelo oluzenzakalelayo olunezici namakhono athuthukile.

◇ 3. Isabelomali siyinto ebalulekile okufanele uyicabangele lapho ukhetha umshini webhizinisi lakho. Ngenkathi ubala isabelomali qiniseka ukuthi ucabangela izici ezahlukene njengokusetshenziswa kwamandla kanye nezindleko zokulungisa.

◇ 4. Yenza ukuhlolwa kokuhambisana kwezinto zokupakisha nomshini wokupakisha ngaphambi kokukhetha umshini.

◇ 5. Khetha umhlinzeki womshini onokwethenjelwa, njenge-Smart Weigh, ngoba isevisi yangemva kokuthengisa nayo iyinto ebalulekile okufanele icatshangelwe.

Imicabango Yokugcina

Manje njengoba usuyazi ngomshini wokupakisha impuphu kanye nomshini wokupakisha we-granule, ukukhetha okufanele ibhizinisi lakho kufanele kube lula. Ngezimboni ezahlukene kanye nezinhlobo zemikhiqizo ephathwa yile mishini, ukuthola inketho efanele kuzokusiza ukuthi ubeke ibhizinisi lakho endleleni efanele. Izinketho ezahlukene zomshini okuxoxwe ngazo ngenhla zonke zinikezwa yi-Smart Weigh. Xhumana nathi namuhla futhi thina njengomkhiqizi wemishini yokupakisha onolwazi sizokusiza ukhethe umshini ofanele ngokusekelwe ezidingweni zakho kanye nesabelomali sakho.

I-Smart Weight ingumholi womhlaba wonke ezinhlelweni zokupakisha ezinesisindo esinembile kakhulu nezihlanganisiwe, ethenjwa amakhasimende angaphezu kwe-1,000 kanye nemigqa yokupakisha engaphezu kwe-2,000 emhlabeni jikelele. Ngokusekelwa kwendawo e- Indonesia, eYurophu, e-USA nase-UAE , sinikeza izixazululo zomugqa wokupakisha we-turnkey kusukela ekuphakeleni kuya ekufakeni ama-pallet.

Isixhumanisi Esisheshayo

Umshini Wokupakisha