What is the Difference Between Powder Packing and Granule Packing Machine?

If you are looking to understand the difference between a powder and granule packaging machine, then you have come to the right place. Being said that, choosing the right set of equipment is of critical importance for businesses. Just the machinery can make all the difference between a good quality product and a bad one. Additionally, it can also impact the operational productivity. In this article, we will discuss about powder packaging machine and granule packing machine, along with the differences between the two machinery types.

What is Powder Packaging Machine?

Good product packaging requires specialized equipment. Being said that, powder packing machine has been specifically designed to package fine, dry, and other lightweight powders. With such a machine, you can pack powders into different containers – like pouches and bottles. Using a specialized machine, you can ensure that the powders are consistently filled with accuracy . Additionally, you can seal the product securely to avoid any contamination and wastage.

Suitable Industries and Types of Powder Handled

A number of industries makes the use of powder bagging machine. For instance - food, pharmaceutical, and chemical are commonly found using such a machine type. In the food segment, the machines can pack flour, spices, milk powder, and protein powder. Businesses in the pharmaceutical sector use the machine for packaging medicinal powders and dietary supplements. Chemical industry, whereas, uses the machine for filling up detergents and fertilizers, among other things.

Types of Powder Packing Machines

✔1. Powder Pouch Packing Machine with Auger Filler

This machine can quickly and automatically pack a wide range of powders including chili powder, coffee powder, milk powder, matcha powder, soybean powder, and wheat flour. the powder pouch filling machine with auger filler and screw feeder. The closed design can effectively avoid powder leakage and reduce dust pollution.

▲Key Features:

● Auger Filler and Screw Feeder: At the heart of this machine is the auger filler, a precision mechanism that measures and dispenses the exact amount of powder into each pouch. Paired with a screw feeder, it ensures a steady and consistent flow of powder from the hopper to the filling station, reducing inconsistencies and enhancing efficiency.

● Closed Design: One of the standout features of this machine is its fully enclosed structure. This design effectively prevents powder leakage during operation, minimizing product waste. Additionally, it significantly reduces dust pollution, creating a cleaner and safer working environment for operators—a critical advantage in industries like food processing or pharmaceuticals where hygiene is paramount.

●High Speed and Automation: The machine is engineered for rapid packaging, making it an excellent choice for high-volume production lines. Its fully automated system streamlines the process from powder dispensing to pouch sealing, reducing the need for manual labor and boosting overall productivity.

✔2. Powder Vertical Packaging Machine with Screw Conveyor

The vertical coffee powder packaging machine is suitable for packing various powders including flour, corn flour, coffee, and fruit powder. The speed of this machine is adjusted by frequency conversion with the range, and the actual speed depends on type of products and pouch.

▲Key Features:

● Screw Conveyor: This machine features a screw conveyor that efficiently transports powder from the storage hopper to the filling station. The conveyor ensures a controlled and consistent flow, making it especially effective for fine, free-flowing, or challenging powders that might otherwise clog or settle unevenly.

● Adjustable Speed via Frequency Conversion: The packaging speed of this machine can be customized using frequency conversion technology. This allows operators to adjust the speed within a specific range, tailoring it to the needs of the production line. The actual speed achieved depends on factors such as the type of powder being packed (e.g., its density or flowability) and the pouch material (e.g., plastic, laminated film), providing operational flexibility.

● Vertical Design: As a vertical packaging machine, it forms pouches from a roll of film, fills them with powder, and seals them in a continuous process. This design is space-efficient and well-suited for high-throughput environments.

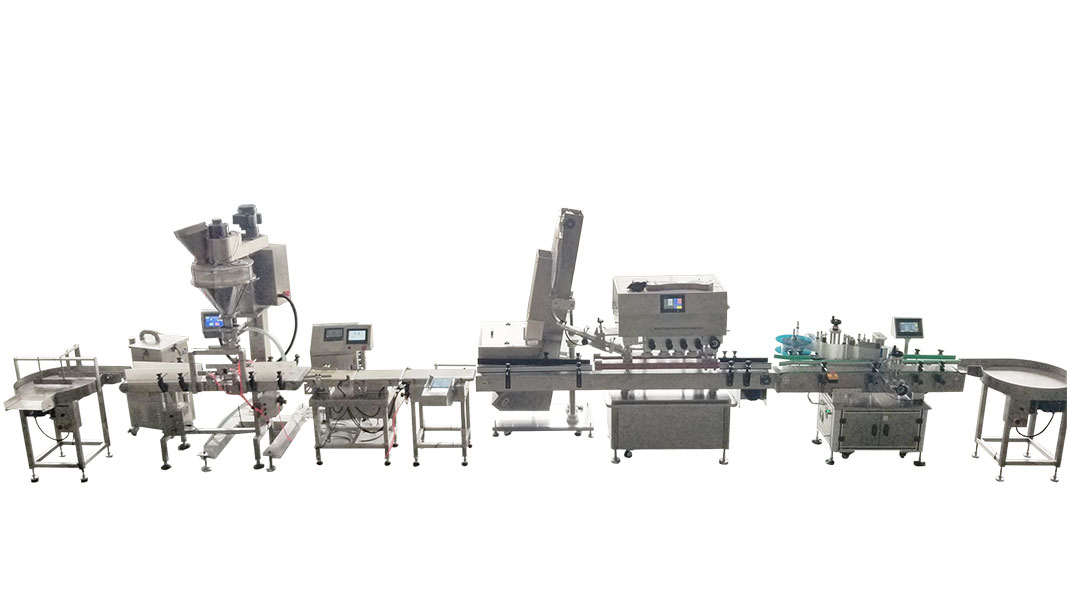

✔3. Powder Bottle filling Packaging Machine

This packing machine is better suited for various types of cans such as plastic, tinplate, paper, and aluminum. Businesses across industry verticals - such as food and pharmaceutical – use this packaging machine.

▲Key Features:

●Versatility in Container Types: This machine’s ability to accommodate different container materials and sizes makes it highly adaptable. Whether a business uses small plastic jars for spices or large aluminum cans for nutritional powders, this machine can handle the task, reducing the need for multiple specialized machines.

● Precision Filling: The machine is equipped with mechanisms to ensure accurate filling of powders into each container. This precision minimizes overfilling or underfilling, ensuring consistent product weight and reducing material waste—a key consideration for cost-conscious operations.

● Wide Industry Applications: It is extensively used across various sectors, including:

▶ Food Industry: For packaging powders like spices, baking mixes, protein powders, and instant drink mixes.

▶ Pharmaceutical Industry: For filling powdered medications, vitamins, or health supplements into bottles or cans, where accuracy and hygiene are critical.

What is Granule Packaging Machine?

The Granule packaging machine is specifically designed to handle products having a granular structure. This can include small grains and larger pellets. The use of this machine ensures that the products are packaged with accuracy and efficiency. This ensures ease of transport and enhance quality.

Suitable Industries and Types of Granules Handled

Businesses in sectors like food, agriculture, and construction are found using a granule filling machine. Being said that, it is used for packaging sugar, rice, cereals, and other food items. In the agriculture sector, the machine can be used for packaging fertilizers, seeds, and animal feed. Whereas, in the construction industry, the machine can pack building materials including sand and gravel.

Types of Granule Packing Machines

▶1. Automated Multihead Pouch Packing Machine

A multihead weigher pouch packing machine is a specialized system designed to fill and seal pre-formed pouches with a precise amount of product. At its core is the multihead weigher, a machine equipped with multiple weigh heads (or hoppers) that work together to measure and dispense products accurately. Here’s how it operates:

● Weighing Process: The product is distributed into several weigh hoppers, each measuring a portion of the total weight. The machine’s software calculates the combination of hoppers that most closely matches the target weight and releases that amount.

● Filling and Sealing: The precisely weighed product is then dispensed into a pre-formed pouch. The pouch packing machine fills the pouch and seals it, often using heat or other sealing techniques, to create a finished package.

▼Applications: This setup is ideal for products that need to be packaged in specific quantities, such as:

◇ Snacks (e.g., chips, nuts)

◇ Pet food

◇ Frozen foods

◇Confectionery (e.g., candies, chocolates)

▲Key Features:

● Pouches can be customized in size, shape, and material (e.g., plastic, foil).

● Ensures consistency and reduces product waste by minimizing overfilling.

▶2. Multihead Vertical Packing Machine

A multihead weigher vertical packing machine, commonly known as a vertical form fill seal (VFFS) machine, takes a different approach by creating bags from a continuous roll of film. Integrated with a multihead weigher, it offers a seamless, high-speed packaging process. Here’s how it works:

● Bag Formation: The machine pulls a roll of flat film, shapes it into a tube, and seals the edges to form a bag.

● Weighing Process: Similar to the pouch packing machine, the multihead weigher measures the product using multiple hoppers and dispenses the exact amount into the newly formed bag.

● Filling and Sealing: The product drops into the bag, and the machine seals the top while cutting it from the film roll, completing the package in one continuous operation.

▼Applications: This system excels at packaging a wide variety of products, including:

● Granules (e.g., rice, seeds, coffee)

●Small hardware items (e.g., screws, nuts)

● Snacks and other free-flowing products

▲Key Features:

●High-speed operation makes it suitable for large-scale production.

● Versatile bag sizes and styles can be produced by adjusting the film and settings.

Key Differences Between Powder And Granule Packaging Machines

Do not confuse yourself. Both of these machine types have been designed to pack products with accuracy and efficiency. However, there are some differences between the powder and granule filling machines.

◆1. Product Handling

The powder packing machine has been specifically designed with features to prevent dust generation and loose powders. Whereas, granule packing machine have been designed to handle free-flowing products.

◆2. Sealing Techniques

In powder packaging machine, the sealing mechanism has been designed to avoid trapping fine powder in the seal area. Often integrate dust extraction or air-tight sealing to avoid product loss.

◆3. Filing Mechanism

For controlling the flow of fine particles, the powder bagging machine makes use of auger fillers. Granule machines, on the other hand, uses weighing systems to measure and dispense products.

How to Choose the Right Machine for Your Needs?

Investing in an industrial equipment is not just an expensive process, but it can also be a one-time thing for most businesses. Therefore, doing the right investment becomes even more critical. Being said that, to choose the right machine, it is important that you have the appropriate know-how of the products and their characteristics. Here is the list that will help you choose the right machine based on your requirements.

◇1. Determine whether your product is of fine powder or granule type and then choose the required type.

◇2. If you require high production rate then select an automatic system with advanced features and capabilities.

◇3. Budget is also a crucial consideration while selecting the machine for your business. While accounting for budget make sure to consider different factors such as energy consumption and maintenance costs.

◇4. Do a compatibility test of the packaging material with the packaging machine before selecting the machine.

◇5. Choose a reliable machine provider, like Smart Weigh, because after-sales service is also a critical consideration.

Final Thoughts

Now that you know about the powder packaging machine and granule packing machine, doing the right selection for your business should be easier. With the different industries and types of products handled by these machines, getting the right option will help you put your business on the right path. The different machine options discussed above are all provided by Smart Weigh. Get in touch today and we as an experienced packaging machines manufacturer will help you select the right machine based on your requirements and budget.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine