Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Vertical packaging machines are widely used in food and non-food industries, and are suitable for various granular materials, such as potato chips, coffee beans, dried fruit, nuts, grains, pet food, seeds, tablets, iron nails, etc. Here we mainly introduce the coffee beans packaging system, which consists of Z-type elevator, VFFS packaging machine, combination weigher, and output conveyor. Coffee beans weighing 10-2000 grams can be weighed by a 14 head multihead weigher. In addition, in order to prevent the clogging of puffed materials, the function of feeding in sequence can be adopted, and the deep U-shaped linear vibration plate can prevent leakage of fine particles, which can effectively improve the weighing accuracy. Packing speed, type, length and width can be selected according to your needs. In addition, we provide customized services according to your actual needs.

l Automatic coffee beans packing machine for sale high quality

l The structure of small vertical type filling sealing machine for coffee beans

l Automatic coffee beans packing machine parameters

l Features & benefits of coffee beans pouch packing machine

l Do you know these things about coffee beans packing machine price?

l Applications of coffee beans packing machine

l Why choose us – Guangdong Smart weigh pack?

l Contact us

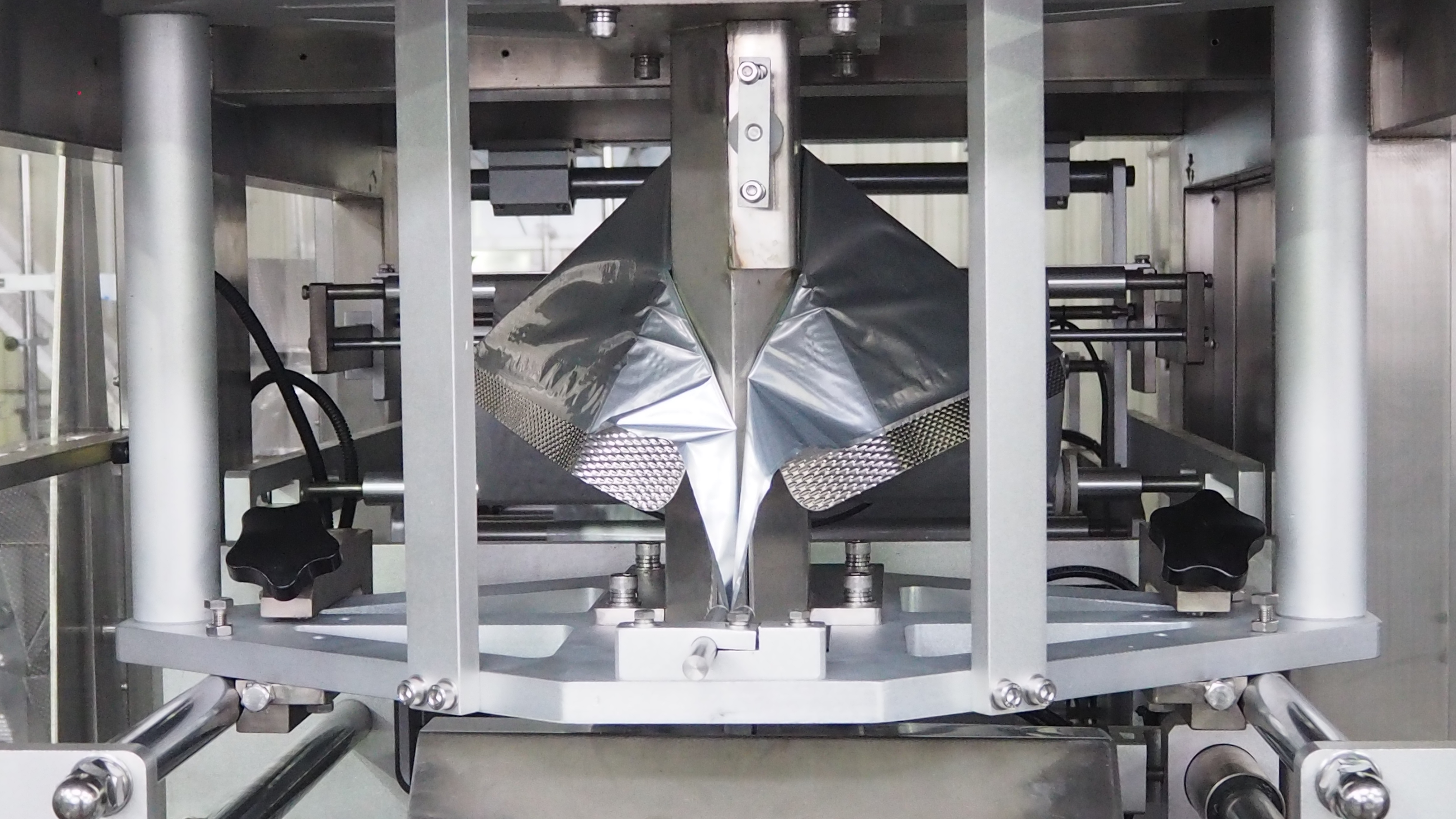

Coffee bean packaging machine can be equipped with a 10-head/14-head combination weigher, which is suitable for coffee beans of 10-1000g and 10-2000g per bag. Vertical form fill seal packing machine can automatically complete coding (optional), bag making, filling, sealing and cutting, and forming output, with high packaging efficiency, stable operation and high cost performance. Customers can choose different types of vertical packing machines according to different sealing methods, such as back sealing and four-side sealing.

In addition, according to your actual needs, you can also choose some other equipment, such as check weighers and metal detectors, to reject unqualified weight and metal-containing products. We also support custom services. Here we mainly discuss the automatic coffee bean packing machine.

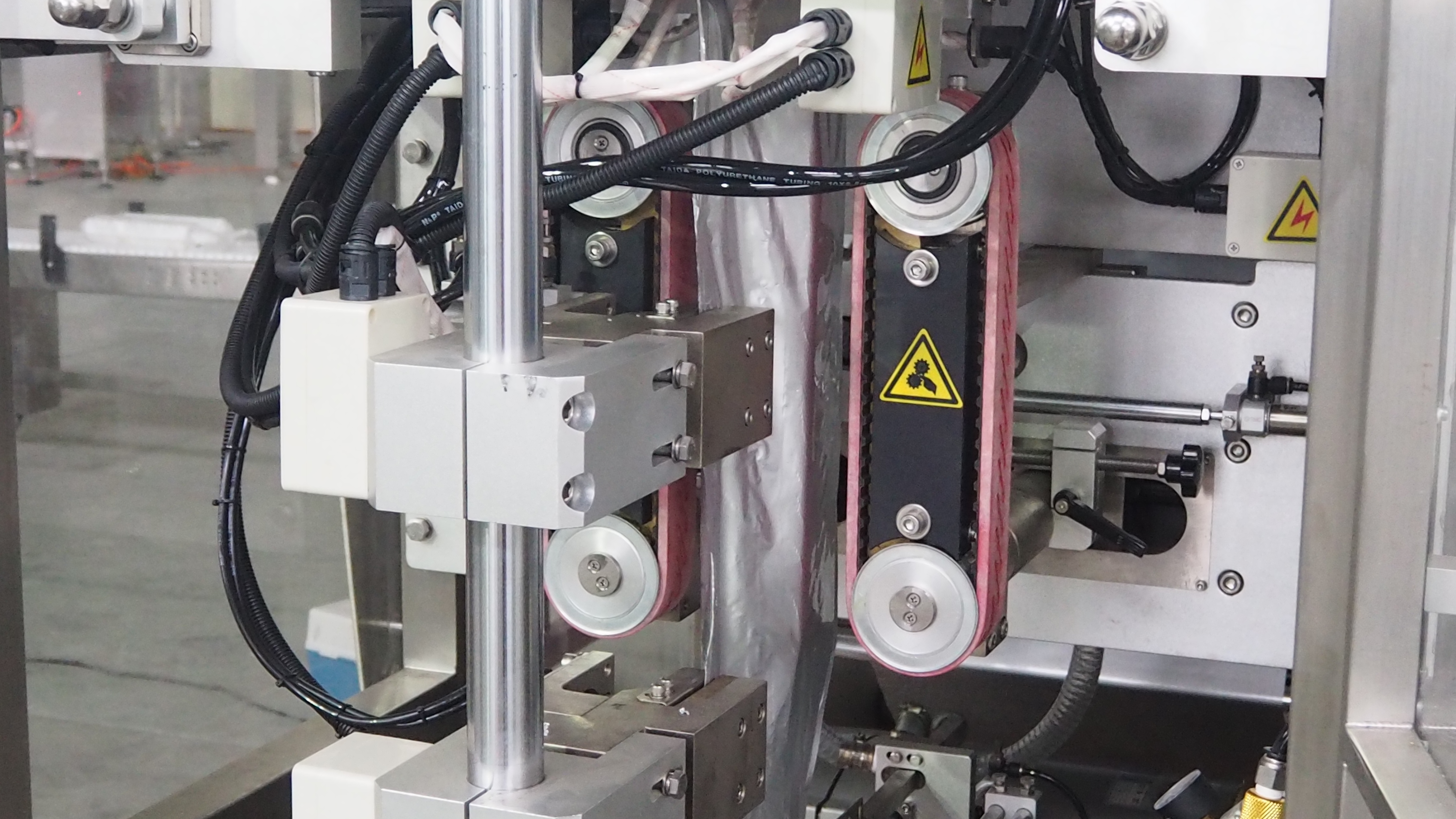

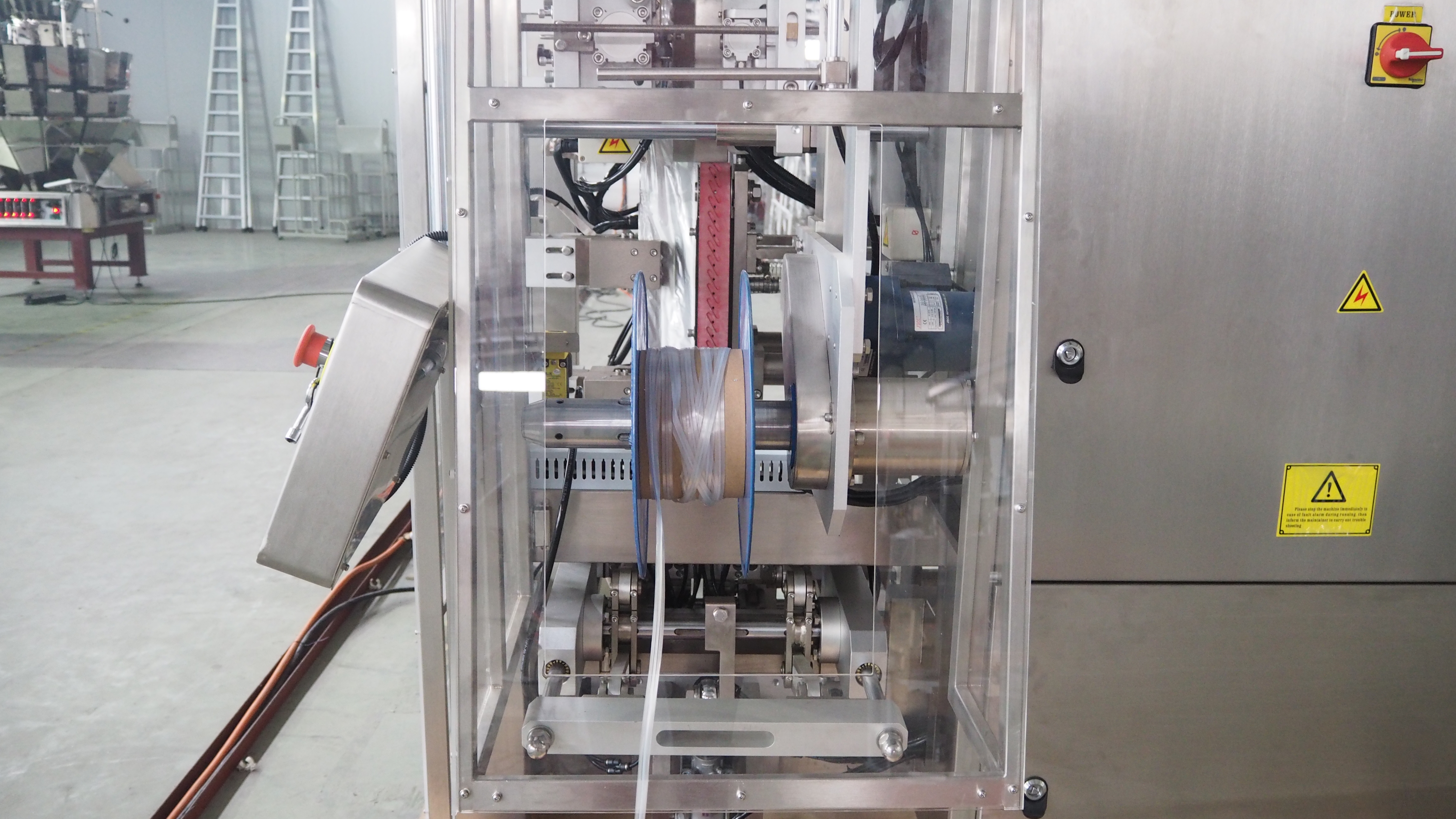

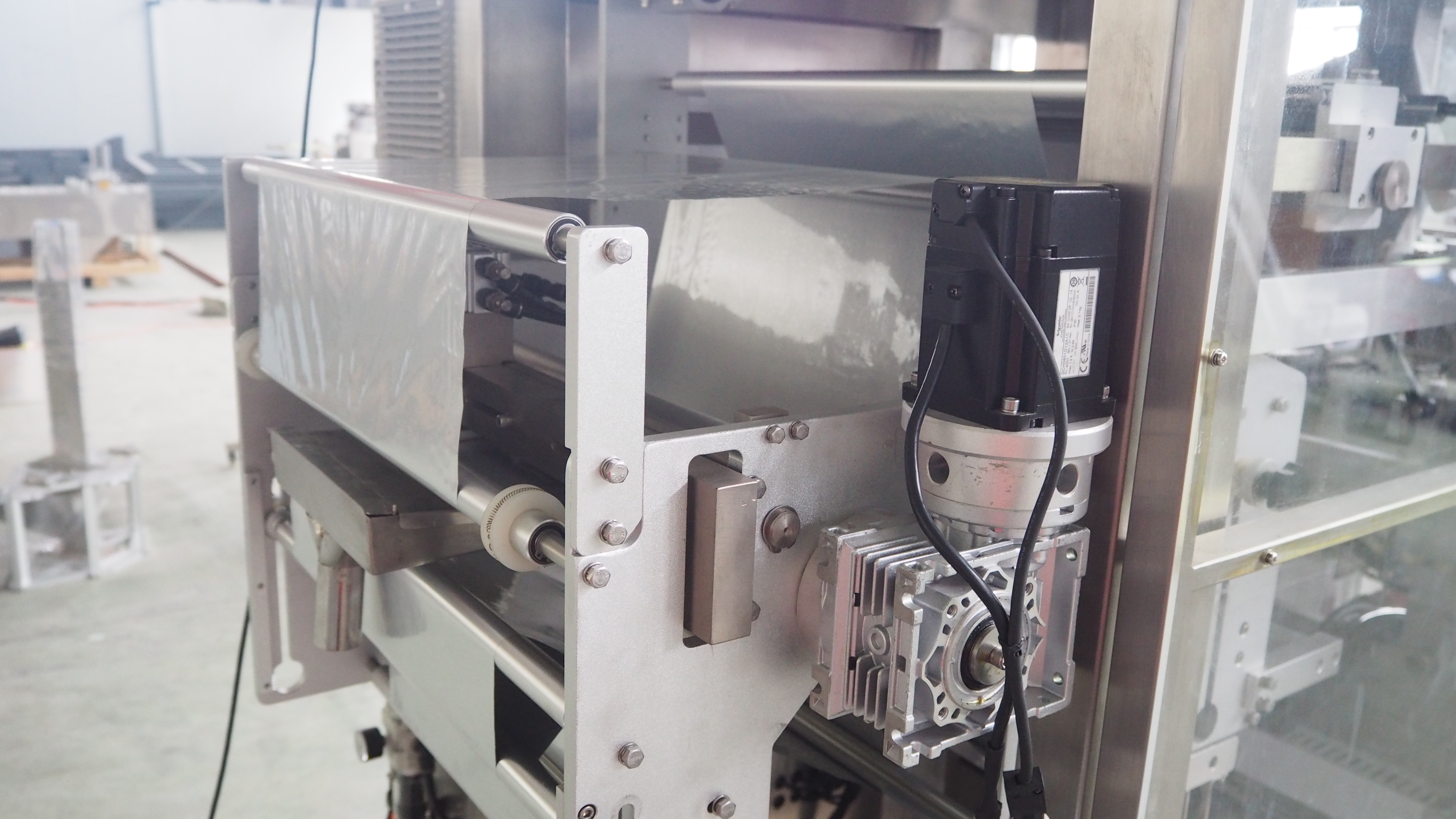

The vertical packaging machine adopts roll film bag making, equipped with servo motor film pulling device, precise positioning, automatic deviation correction, and low noise. The fuselage is made of 304 stainless steel and consists of PLC touch screen, packaging film frame, filling equipment, bag making machine, sealing and cutting device. PLC touch screen controls language, packing accuracy, packing speed, and temperature. The multi-head weigher has high weighing accuracy and has the function of photoelectric eye detection. Customers can automatically or manually adjust the feeding amplitude according to the characteristics of the material.

In addition, the heat sealing and cutting devices are covered by protective devices. Usually, many customers buy date printers and gusset bags to match coffee bean packing machines.

Model | SW-PL1 |

System | Multihead weigher vertical packing system |

Application | Granular product |

Weigh range | 10-1000g (10 head); 10-2000g (14 head) |

Accuracy | ±0.1-1.5 g |

Speed | 30-50 bags/min (normal) 50-70 bags/min (twin servo) 70-120 bags/min (continuous sealing) |

Bag size | Width=50-500mm, length=80-800mm (Depends on packing machine model) |

Bag style | Pillow bag, gusset bag, quad-sealed bag |

Bag material | Laminated or PE film |

Weighing method | Load cell |

Control penal | 7" or 10" touch screen |

Power supply | 5.95 KW |

Air consumption | 1.5m3/min |

Voltage | 220V/50HZ or 60HZ, single phase |

Packing size | 20”or 40”container |

ü PLC control system, more stable and accuracy output signal, bag-making, measuring, filling, printing, cutting, finished in one operation;

ü Separate circuit boxes for pneumatic and power control. Low noise, and more stable;

ü Film-pulling with servo motor for precision, pulling belt with cover to protect moisture;

ü Open door alarm and stop machine running in any condition for safety regulation;

ü Film centering automatically is available (Optional);

ü Only control touch screen to adjust bag deviation. Simple operation;

ü Film in roller can be locked and unlocked by air, convenient while change film;

Coffee bean packing machine price is affected by many aspects, such as machine model, material, performance, degree of automation and accessories, etc. Customers should choose the most cost-effective weighing and packaging solution according to their own packaging needs and material characteristics.

Model: 10-head/14-head weighing machine SW-P620/720 vertical packaging machine/SW-V460 vertical packaging machine

Material: SUS304 stainless steel

Performance: fast speed, high precision and stable operation. According to most customer feedback, the packaging machines produced by Smart Weigh have low maintenance costs and only require daily film changes.

Degree of automation: fully automatic/semi-automatic weighing and packaging system

Accessories: large inclination conveyor/Z type conveyor/single bucket conveyor platform, output conveyor, rotating table, optional: check weigher, metal detector, date printer, nitrogen generator, etc.

Mental detector

Mental detector

VFFS packing machine for coffee bean has been widely used in packaging a variety of granular materials and can make different bag types. Common packaging materials include pet food, potato chips, biscuits, nuts, cereals, rice, yogurt cubes, candy, banana chips, dried sweet potatoes, etc. There are three-side sealing, back-sealing and four-side sealing for small bags. Bag types include pillow bag, gusset bag, quad bag, etc. The size of the bag depends on the bag maker on the coffee bean packing machine, so you can choose the right bag maker according to your needs. Our automatic vertical packaging equipment can greatly improve production efficiency. In addition, we provide customized services according to your actual requirements.

Granule material

Bag type

Guangdong Smart weigh pack integrates food processing and packaging solutions with more than 1000 systems installed in more than 50 countries. With a unique combination of innovative technologies, extensive project management experience and 24-hour global support, our powder packaging machines are exported overseas. Our products have qualification certificates, undergo strict quality inspection, and have low maintenance costs. We will combine customer needs to provide you with the most cost-effective packaging solutions. The company offers a comprehensive range of weighing and packaging machine products, including noodle weighers, salad weighers, nut blending weighers, legal cannabis weighers, meat weighers, stick shape multihead weighers, vertical packaging machines, premade bag packaging machines, tray sealing machines, bottle filling machines etc.

Finally, our reliable service runs through our cooperation process and provides you with 24-hour online service.

How can you meet our requirements and needs well?

We will recommend the suitable model of machine and make the unique design based on your project details and requirements.

What about your payment?

T/T by bank account directly

L/C at sight

How can we check your machine quality after we place an order?

We will send the photos and videos of the machine to you to check their running situation before delivery. What’s more, welcome to come to our factory to check the machine by you own.

How can you ensure you will send us the machine after the balance paid?

We are a factory with business license and certificate. If that is not enough, we can make the deal through L/C payment to guarantee your money.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved