The Source and Working Steps of the Checkweigher

For any manufacturing industry, quality and weight control are some of the most important things to take care of. The core tool companies use to maintain weight consistency throughout their products is the check weight tool.

It's needed most especially in businesses like food production, consumer goods, pharma products, and other sensitive manufacturing.

Wondering how it works? Don't worry. This guide will cover everything you need to know, starting from what a checkweigher is to its working steps.

What is a Checkweigher?

A automatic checkweigher is a machine that automatically checks the weight of packaged goods.

Each product is scanned and weighed to see if the product is within the perfect weight as per set standards. If the weight is too heavy or too light, it’s rejected from the line.

Wrong weight in products could harm the reputation of the company and also cause some legal troubles if it goes against compliance.

So, you need to ensure each item is correctly weighted to avoid a fine and maintain trust.

History of Check Weighers

The concept of weighing products during production has been around for over a century. In earlier days, the checkweigher machines were pretty mechanical, and humans had to do most of the work.

As the technology evolved, the check weighers became automatic. Now, the checkweighers can easily reject a product if the weight is not accurate. Modern check weigher machine can also integrate with other parts of the production line to enhance your production process.

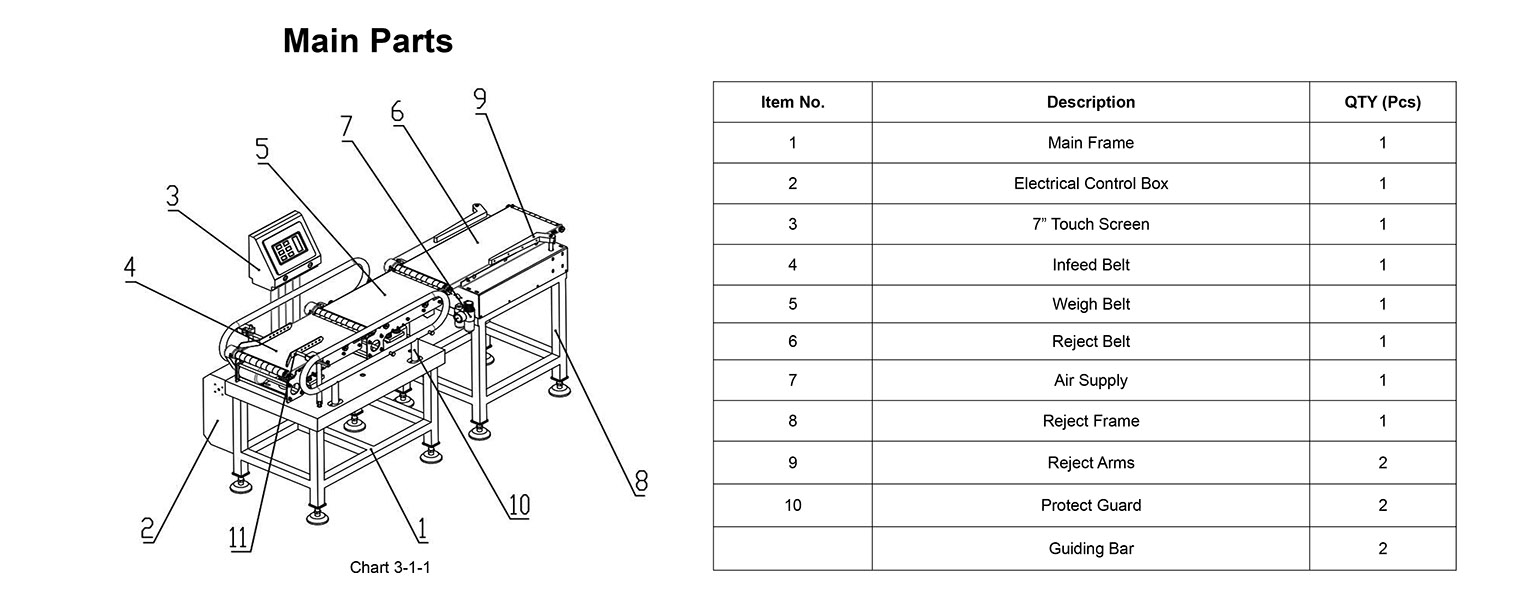

How a Checkweigher Works Step-by-Step

To better understand, let's see a step-by-step guide on how a check weigher system works.

◆Step 1: Feeding the Product onto the Conveyor

The first step is introducing the product onto the conveyor belt.

Most companies use an infeed conveyor to deploy the products evenly. With the infeed conveyor, the products are deployed perfectly without collisions or bunching and maintain proper space.

◆Step 2: Weighing the Product

As the product moves along the conveyor, it reaches the weighing platform or weighing belt.

Here, highly sensitive load cells measure the weight of the item in real-time.

The weighing happens very quickly and doesn’t stop the production line. So, a high volume of goods can pass easily.

◆Step 3: Comparing the Weight with Set Standards

After the system captures the weight, it immediately compares it with the preset acceptable range.

These standards can vary based on product type, packaging, and regulations. You can also set the standards in some machines. Further, some systems also allow different target weights for different batches or SKUs.

◆Step 4: Accepting or Rejecting the Product

Based on the comparison, the system then either allows the product to continue down the line or diverts it.

If an item is outside the specified weight range, the automatic checkweigher machine triggers a mechanism to reject the product. It usually is a pusher arm or drop belt. Some of the machines also use an air blast for the same purpose.

In the end, the check weigher sends the product for further classification as per your packing system.

Now, most things depend on the check weigher machine. So, let's check out some of the best check-weighing solutions.

Checkweighing Solutions from Smart Weigh

Choosing the right checkweigher machine will solve most of the problems. Let's see some of the best check-weighing solutions you should get for proper quality control.

▶Smart Weigh High Precision Belt Checkweigher

The High Precision Belt Checkweigher from Smart Weigh is built for speed and accuracy. It can handle a wide range of product types and sizes.

Due to its precision belt, it's a perfect fit for industries such as food, pharmaceuticals, and cosmetics.

It comes with advanced load-cell technology, and that’s the unique feature of the machine. With highly accurate weight readings, the products move at a very high speed, giving you the ultimate speed and momentum.

The belt system is designed to minimize vibration. It also has easy integration options with your entire system.

▶Smart Weigh Metal Detector with Check Weigher Combo

For companies that require both weight verification and metal detection, Smart Weigh's Metal Detector with Checkweigher Combo is an ideal solution.

It combines two critical quality control functions into a single compact machine. This combo unit not only checks that products are within the correct weight range but also detects any metal contaminants that might have accidentally entered during production. It provides a complete safeguard for brands that must adhere to the highest safety and regulatory standards.

Not to mention, just like all the other systems from Smart Weigh, even this combo is fully customizable. It's easy to operate with quick changeover for different batches as well as user-friendly control. If you want reports, you can always use their data collection features to get the details. It's a perfect blend for quality control and weight control.

Things to Keep in Mind for Smooth Operations

While checkweigher machines are highly reliable, smooth operations depend on a few key practices:

· Regular Calibration: Regular calibration habits will increase the accuracy of your machine.

· Proper Maintenance: Regularly clean the belts and other parts. If your product has more dust or gets dirty quickly, you should clean it more often.

· Training: Train your staff for faster execution.

· Data Monitoring: Keep track of the reports and maintain the product accordingly.

· Choose the Right Company and Product: Make sure you have bought the machine from the right company and you’re using the right product for you.

Conclusion

A check weigher is much more than a simple weighing machine. It’s needed for brand trust and to avoid hefty fines from the government body. Using a check weigher will also save you some extra costs from overloading the packages. As most of these machines are automatic, you don't need a lot of staff to maintain them.

You can simply integrate it with your entire machine system. If your company is exporting goods via flight and there is a chance of metal going inside the product, you should select the combo. For other checkweigher manufacturers, the Smart Weigh's High Precision Belt Checkweigher Machine is a good choice. You can learn more about the products by visiting their page or contacting the team.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine