Company Advantages1. The manufacture of Smartweigh Pack is the application of various basic mechanical parts. They include gears, bearings, fasteners, springs, seals, couplings, and so forth. On Smart Weigh

packing machine, savings, security and productivity have been increased

2. Because of its continuous use, fewer technicians are needed for operation and oversight, which significantly helps cut overall labor expenses. Smart Weigh packing machines are of high efficiency

3. It has the proper size in consideration of the force. Each element of this product is designed with the most suitable size by considering the force acting on it and the permissible stresses for the material used. Smart Weigh packing machine has set new benchmarks in the industry

4. It has good strength. The whole unit and its components have the proper sizes which are determined by the stresses so that failure or deformation does not occur. Smart Weigh pouch protects products from moisture

5. This product has the required strength. It has been tested according to standards such as MIL-STD-810F to evaluate its construction, materials, and mounting for ruggedness. Smart Weigh packing machine is manufactured with the best available technical know-how

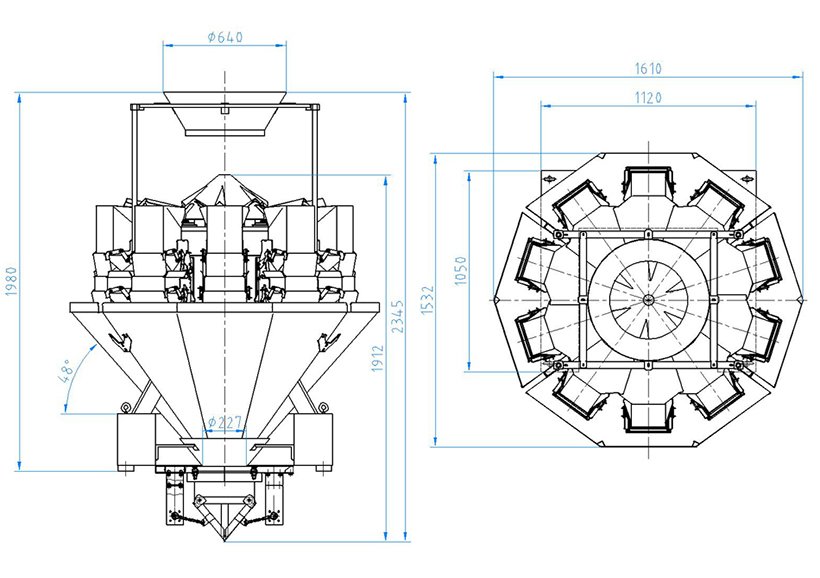

Model | SW-ML10 |

Weighing Range | 10-5000 grams |

Max. Speed | 45 bags/min |

Accuracy | + 0.1-1.5 grams |

Weigh Bucket | 0.5L |

Control Penal | 9.7" Touch Screen |

Power Supply | 220V/50HZ or 60HZ; 10A; 1000W |

Driving System | Stepper Motor |

Packing Dimension | 1950L*1280W*1691H mm |

Gross Weight | 640 kg |

◇ IP65 waterproof, use water cleaning directly, save time while cleaning;

◆ Four side seal base frame ensure stable while running, big cover easy for maintenance;

◇ Modular control system, more stability and lower maintenance fees;

◆ Rotary or vibrating top cone can be selected;

◇ Load cell or photo sensor checking to satisfy different requirements;

◆ Preset stagger dump function to stop blockage;

◇ 9.7' touch screen with user friendly menu, easy to change in different menu;

◆ Checking signal connection with another equipment on the screen directly;

◇ Food contact parts disassembling without tools, which is easier to clean;

Part1

Rotary top cone with unique feeding device, it can separate salad well;

Full dimplete plate keep less salad stick on the weigher.

Part2

5L hoppers are design for salad or big weght products volume;

Each hopper is exchangeable.;

It is mainly apply in automatic weighing various granular products in food or non-food industries, such as potato chips, nuts, frozen food, vegetable, sea food, nail, etc.

Guangdong Smart Weigh Packaging Machinery Co., Ltd delivers high quality and cost effective bagging machine with exceptional customer support. We have experienced product management professionals. They have exceptional abilities in problem analyzing and solving with regard to product development, design, and production.

2. Our company has excellent management. They can solve many complex problems by thinking ahead, developing emergency plans, balancing competing interests, and adopting analytical methods.

3. We have been focusing on international market expansion. So far, we have established business cooperations in the USA, South Africa, Australia, the UK, and so other countries. We aim at continuous quality improvement. We continuously improve ourselves by viewing the business from a “Glass Half Empty” perspective to intensely focus us on how we can stand firm in the market.