Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Integrated rotary pouch packing machine engineered to dose, fill, seal, inspect, and discharge pre-made pouches of brown sugar in one continuous cycle.

SEND INQUIRY NOW

Upgrade your production with Smart Weigh's automatic brown sugar packing machine, an integrated rotary pouch packing machine engineered to dose, fill, seal, inspect, and discharge pre-made pouches of brown sugar in one continuous cycle. Purpose-built for procurement managers and plant engineers, this professional-grade brown sugar packaging machine boosts throughput, keeps weights consistent, and locks in freshness—all while meeting the most demanding food-safety standards.

1. Feed Conveyor: Choose from a bucket or incline conveyor to automatically deliver pretzels into the weighing machine.

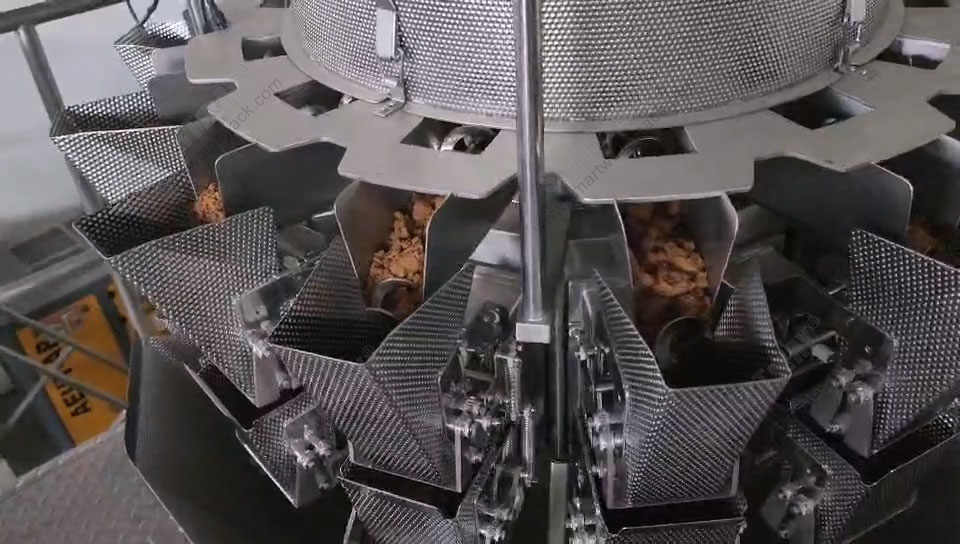

2. 14-Head Screw Multihead Weigher: A commonly utilized, high-speed weighing solution offering exceptional accuracy.

3. Support Platform: Provides a stable, elevated structure to securely hold and support the machinery.

4. Pouch Packing Machine: Efficiently fills and seals products into pouches, ensuring consistent packaging quality.

Optional Add-ons

1. Date Coding Printer

Thermal Transfer Overprinter (TTO): Prints high-resolution text, logos, and barcodes.

Inkjet Printer: Suitable for variable data printing directly on packaging films.

2. Metal Detector

Integrated Detection: Inline metal detection to identify ferrous and non-ferrous metal contaminants.

Automatic Rejection Mechanism: Ensures contaminated packages are removed without halting production.

3. Secondary Wrapping Machine

Smartweigh's Wrapping Machine for Secondary Packaging is a high-efficiency solution designed for automatic bag folding and intelligent material management. It ensures precise, neat packaging with minimal manual intervention while optimizing material usage. Perfect for diverse industries, this machine seamlessly integrates into production lines, enhancing both productivity and packaging aesthetics.

| Weighing Range | 100 grams to 2000 grams |

|---|---|

| Number of Weighing Heads | 14 head |

| Packing Speed | 8 Station: 50 packs/min |

| Pouch Style | Premade pouch, flat pouches, zipper pouch, stand up bags |

| Pouch Size Range | Width: 100 mm - 250 mm Length: 150 mm – 350 mm |

| Power Supply | 220 V, 50/60 Hz, 3 kW |

| Control System | Multihead weigher: modular board control system with 7-inch touch screen Packing machine: PLC with 7-inch color touch-screen interface |

| Language Support | Multilingual (English, Spanish, Chinese, Korea, etc.) |

This automatic rotary premade pouch packaging system features multiple stations arranged in a circular layout. Sitcky brown sugar pouch packaging machine is handled seamlessly through each stage of the process:

1. Pouch Loading & Opening – Vacuum arms load each pouch into the eight-station carousel and blow it fully open.

2. Precision Weighing & Filling – The screw multihead weigher handle sticky brown sugar, accurately weighs and drops exact brown-sugar charges with gentle angles to avoid powder plumes.

3. In-Process Inspection – "No-pouch-no-fill" and "no-pouch-no-seal" logic eliminate spills and rejects.

4. Heat Sealing – Constant-temperature jaws form an airtight hermetic seal; optional second crimp for retail finish.

5. Discharge & Accumulation – Finished packs exit onto the takeaway conveyor and collection table, ready for boxing.

Throughout this rotary workflow, the machine's intermittent motion indexing ensures each pouch stops at exactly the right position for each operation. The overall process is fully automated and continuous – as one pouch is being filled, another is being sealed, another is being discharged, and so on – optimizing throughput. An intuitive touchscreen HMI (Human-Machine Interface) allows operators to monitor the process in real time, showing station statuses, fill weights, and any fault alarms in clear text. In short, from loading empty pouches to outputting sealed products, the entire packaging cycle is handled with precision and minimal human intervention.

Digital load-cell tech for micro-precision dosing.

Screw feeding handle sticky brown sugar well.

Scrapper hoppers keep less sticky on the hoppers for higher accuracy.

Self-optimising algorithms minimise giveaway under fluctuating humidity.

Designed for premade pouches of almost any style. It works with flat 3- or 4-side sealed pouches, stand-up pouches (doypacks), premade gusseted bags, and pouches with or without resealable zipper closures. Whether your brown sugar is sold in a simple flat pouch or a premium stand-up pouch with a zipper and tear notch, this machine can fill and seal it. (It can even handle special formats like spouted pouches for liquids, though freeze-dried products typically use non-spouted bags.)

High-Speed Operation

Integrated System Design: Synchronization between the multihead weigher and packing machine enables smooth and rapid packaging cycles.

Enhanced Throughput: Capable of packaging up to 50 bags per minute, depending on product characteristics and packaging specifications.

Continuous Operation: Designed for 24/7 operation with minimal maintenance interruptions.

Gentle Product Handling

Minimal Drop Height: Reduces the distance biltong fall during packaging, minimizing breakage and maintaining product integrity.

Controlled Feeding Mechanism: Ensures a steady flow of brown sugar into the weighing system without clogging or spillage.

User-Friendly Interface

Touch-Screen Control Panel: Intuitive interface with easy navigation, allowing operators to monitor and adjust settings effortlessly.

Programmable Settings: Save multiple product parameters for quick changeovers between different packaging requirements.

Real-Time Monitoring: Displays operational data such as production speed, total output, and system diagnostics.

Durable Stainless Steel Construction

SUS304 Stainless Steel: Crafted with high-quality, food-grade stainless steel for durability and compliance with hygiene standards.

Robust Build Quality: Designed to withstand rigorous industrial environments, reducing long-term maintenance costs.

Easy Maintenance and Cleaning

Hygienic Design: Smooth surfaces and rounded edges prevent residue buildup, facilitating quick and thorough cleaning.

Tool-Free Disassembly: Key components can be disassembled without tools, streamlining maintenance procedures.

Compliance with Food Safety Standards

Certifications: Meets international standards such as CE, ensuring compliance and facilitating global market access.

Quality Control: Rigorous testing protocols ensure each machine meets our strict quality benchmarks before delivery.

1. Comprehensive Support

Consultation Services: Expert advice on selecting the right equipment and configurations.

Installation and Commissioning: Professional setup to ensure optimal performance from day one.

Operator Training: In-depth training programs for your team on machine operation and maintenance.

2. Quality Assurance

Stringent Testing Procedures: Each machine undergoes thorough testing to meet our high-quality standards.

Warranty Coverage: We offer warranties that cover parts and labor, providing peace of mind.

3. Competitive Pricing

Transparent Pricing Models: No hidden costs, with detailed quotations provided upfront.

Financing Options: Flexible payment terms and financing plans to accommodate budgetary constraints.

4. Innovation and Development

Research-Driven Solutions: Continuous investment in R&D to introduce cutting-edge features and enhancements.

Customer-Centric Approach: We listen to your feedback to improve our products and services continually.

Ready to take your brown sugar packaging to the next level? Contact Smart Weigh today for a personalized consultation. Our team of experts is eager to help you find the perfect packaging solution tailored to your business needs.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Get Free Quotation Now!

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved