Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Semi automatic weighing and packing line VS Full manual weighing and packing

One food factory manufacture candy, biscuits, seeds etc, one year’s output required is 1800tons(250g/bag, one day’s output is 6 tons), whether need to purchase one set of semi-automatic weighing and packing line to replace present’s full manual weighing and packing, let us analysis:

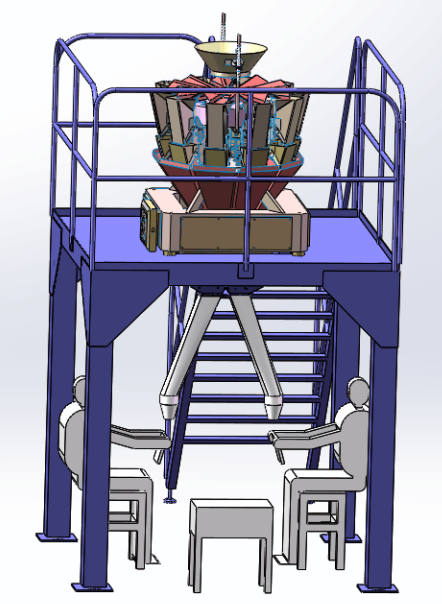

Project 1: Semi-automatic weighing and packing line

1.Budget: Multihead weigher+Platform+band sealer=$10000-12000

2.Output: 50bags/minutes X 60minutes X 8hours x 300days/yearX250g=1800tons/year

3.Accuracy: within+-1g

4.The number of workers: 5 workers/day

Project 2: Full manual weighing and packing

(table weigher for manual weighing, band sealer for manual sealing the bag.)

1.Budget: table weigher+band sealer=$3000-$5000

2.Output and number of worker: Manual feeding, weighing, filling, sealing need 4-5 worker, speed is about 10 bags per minute, one day’t output required is 6 tons, need about 20-25 workers.

3.Accuracy: within+-2g

Comprehensive evaluation:

1.Budget: Project 2 is cheaper compared with Project1($7000’s difference.)

2.Accuracy:Project 1 save product 7-10 tons per year compared with project 2

3.Worker: Project 1 save 15-20 workers per year, if one workers’ salary is $6000 per year, for project 1, which can save$90000-$120000 per year.

Conclusion: Semi automatic packing line is better than full manual weighing and packing line

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved