Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Vertical packing machine with multihead weigher to weigh and pack legums and pulses.

SEND INQUIRY NOW

Model | SW-PL1 |

System | Multihead weigher vertical packing system |

Application | Granular product |

Weigh range | 10-1000g (10 head); 10-2000g (14 head) |

Accuracy | ±0.1-1.5 g |

Speed | 30-50 bags/min (normal) |

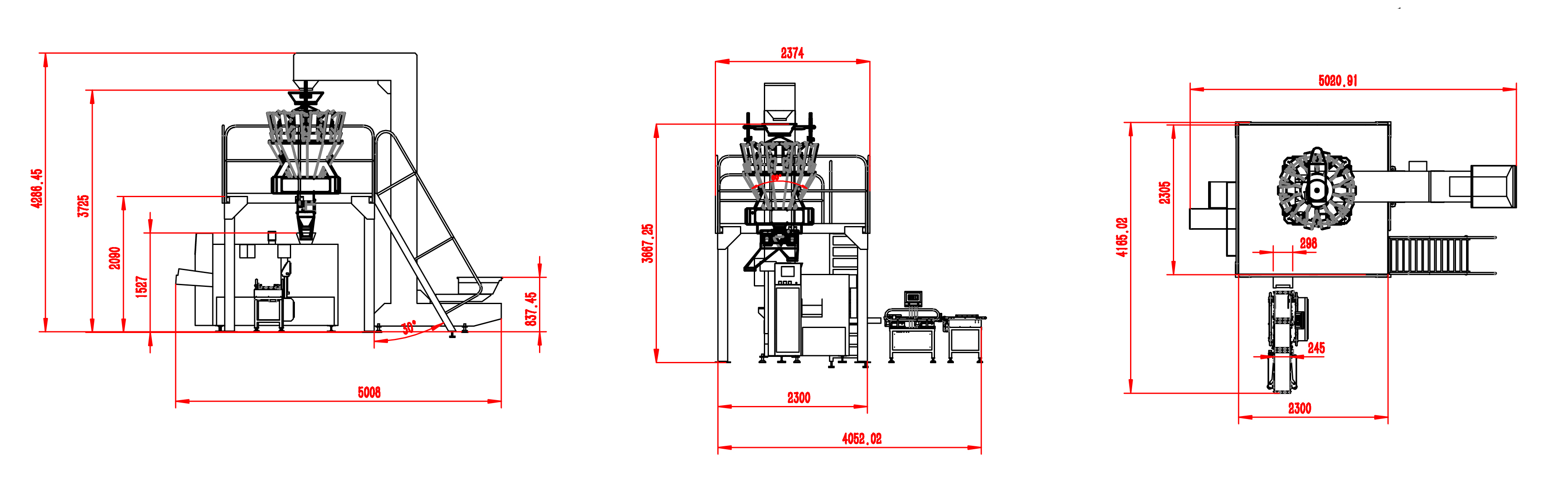

Bag size | Width=50-500mm, length=80-800mm(Depends on packing machine model) |

Bag style | Pillow bag, gusset bag, quad-sealed bag |

Bag material | Laminated or PE film |

Weighing method | Load cell |

Control penal | 7” or 10” touch screen |

Power supply | 5.95 KW |

Air consumption | 1.5m3/min |

Voltage | 220V/50HZ or 60HZ, single phase |

Packing size | 20” or 40” container |

material

The multi head weigher is suitable for weighing granular materials, such as nuts, rice, potato chips, biscuits, etc.

pouch type

Vertical packaging machine adopts roll film forming to make bags, which is suitable for making pillow bags and gusset bags.

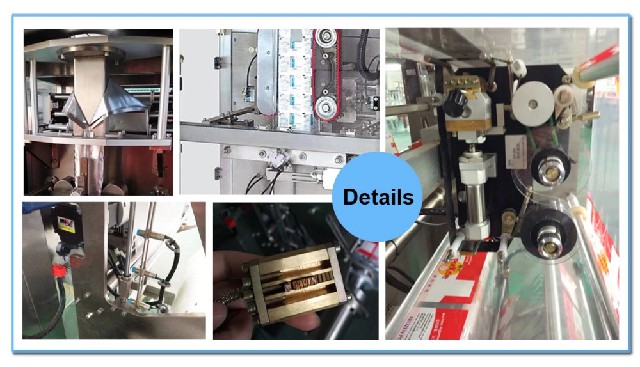

* IP65 waterproof, use water cleaning directly, save time while cleaning;

* Modular control system, more stability and lower maintenance fees;

* Production records can be checked at any time or download to PC;

* Load cell or photo sensor checking to satisfy different requirements;

* Preset stagger dump function to stop blockage;

* Design linear feeder pan deeply to stop small granule products leaking out;

* Refer to product features, select automatic or manual adjust feeding amplitude;

* Food contact parts disassembling without tools, which is easier to clean;

* Multi-languages touch screen for various clients, English, French, Spanish, etc;

* PC monitor production status, clear on production progress (Option).

* Film in roller can be locked and unlocked by air, convenient while change film.

Traditional Model

Normal Driving Board for Multihead Weigher

E. g.10 head mulihead weigher head, one board broken,

One board control 1 head, 1 board broken, 5 head cannot work.

Fix discharge chute, cannot modify after delivery.

Separate Parts

These parts are separately. and then meld together water will get inside the cover if not full meld. this is

not strong enough regarding waterproof while need cleaning.

3 Base Machine Frame

3 side seal base frame with DwO small cover on each size.

Smart Weigh Model

Modular control system

Modular control systemE. g. 10 head mulihead weigher

One board control 1 head, 1 board broken,

only 1 head cannot work, other 9 head can

work continually.

Discharge chute angle can be adjusted

according to different product features.

Combined Parts

Combined PartsUpper cover and middle frame make by mould. which

looks better and very strong in waterproof. what is

more. we make spring dlip on the waterproof rubber.

stop water get inside while vibrator vibrating.

4 Base Machine Frame

Ensure machine frame stable while running

load cell can get higher precision data

Covenient for maintenence

Verbal communication include sounds, words.

4500 Square meter modern factory

30 Existing customized multihead weigher

56 Annual capacity of packaging line

65 Countries We Serve

12 Technical after-sales engineers

24x7 Hours old- aging testing ensure machine run stably and continuously

Spares & Consumables

Strong enough spare parts in stock for old and new version machine.

High Temperature Check

All of the mother boards and drive boards will be tested here

for 7 days at high 50 degree, after 7 days later, if the boards

are survived, then they can be installed on the machine.

Continue Old Age Working

Machine runs 24 hours/day for 1 week continuously to testisfy

there is no problem during production.

1. How can you meet our requirements and needs well?

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Get Free Quotation Now!

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved