Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Model | SW-PL1 |

Weight (g) | 10-1000 G |

Weighing Accuracy(g) | 0.2-1.5g |

Max. Speed | 65 bags/min |

Weigh Hopper Volume | 1.6L |

| Bag Style | Pillow bag |

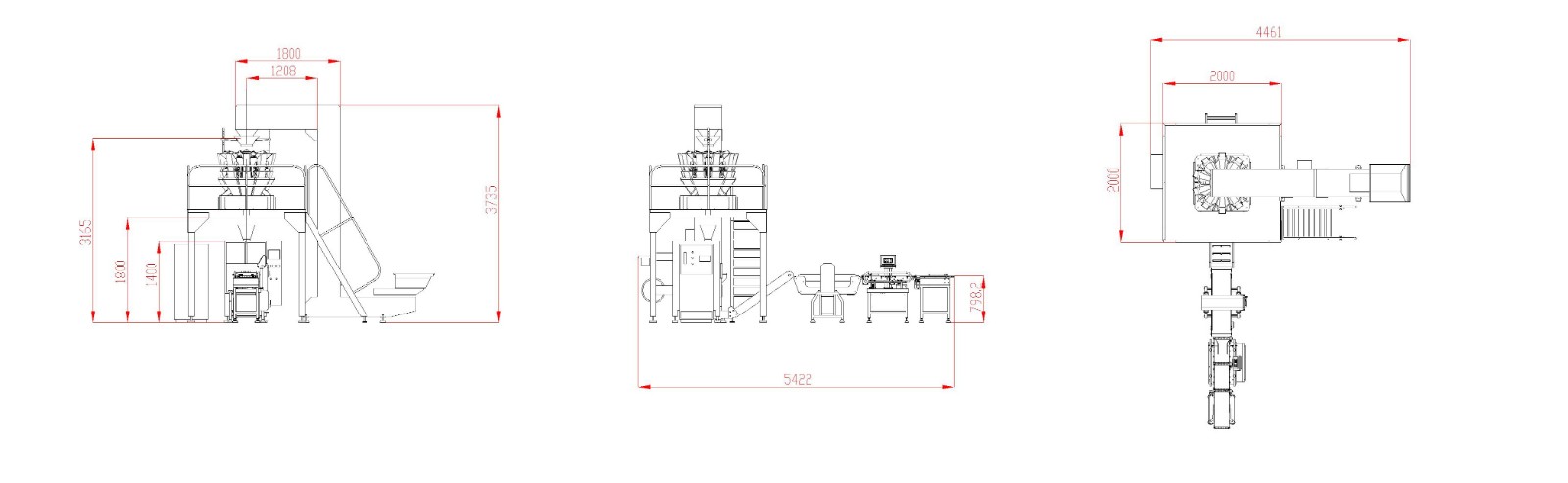

| Bag Size | Length 80-300mm, width 60-250mm |

Control Penal | 7" Touch Screen |

Power Requirement | 220V/50/60HZ |

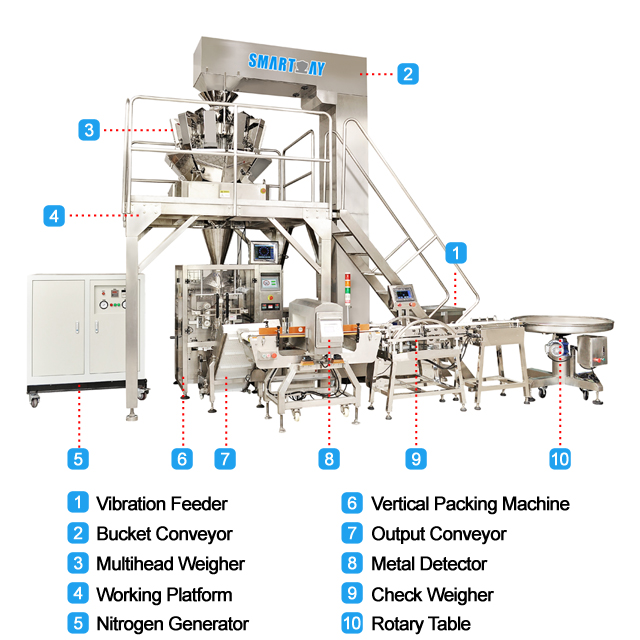

The potato chips packing machine fully-automatically procedures from material feeding, weighing, filling, forming, sealing, date-printing to finished product output.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved