Pagdating sa pagpili ng tamang powder packaging machine, ang kahusayan, katumpakan, at kalidad sa mga pagpapatakbo ng packaging ay dapat ang priyoridad. Hindi mahalaga kung nakikitungo ka sa mga pinong, butil-butil, o malagkit na pulbos, dapat na iayon ang makina sa mga partikular na katangian ng daloy ng produkto at mga kinakailangan sa packaging. Samakatuwid, hindi mo maaaring palampasin ang mga salik gaya ng bilis, uri ng sealing, at katumpakan ng bahagi kapag pumipili ng mga powder at packaging machine.

Sa mga pagsulong sa automation, nag-aalok ang mga powder packing machine ng iba't ibang feature, kabilang ang mga volumetric filler, auger filler, at vacuum sealing upang ma-accommodate ang iba't ibang uri ng produkto. Ang pag-unawa sa mga natatanging pangangailangan ng iyong pulbos, mula sa moisture sensitivity hanggang sa density, ay napakahalaga sa pagpili ng makina na mag-o-optimize ng produksyon at magpapaliit ng basura.

Ang pagpili ng powder bagging machine ay depende sa mga katangian ng powder, tulad ng flowability, laki ng particle, at moisture content. Dapat tiyakin ng makina ang tumpak na dosing, airtight sealing, at mahusay na paghawak ng produkto upang matugunan ang mga pamantayan sa packaging at kaligtasan.

● Mga Volumetric Filler: Tamang-tama para sa libreng dumadaloy na mga pulbos, sinusukat nila ang dami ng produkto para sa pare-parehong paghati.

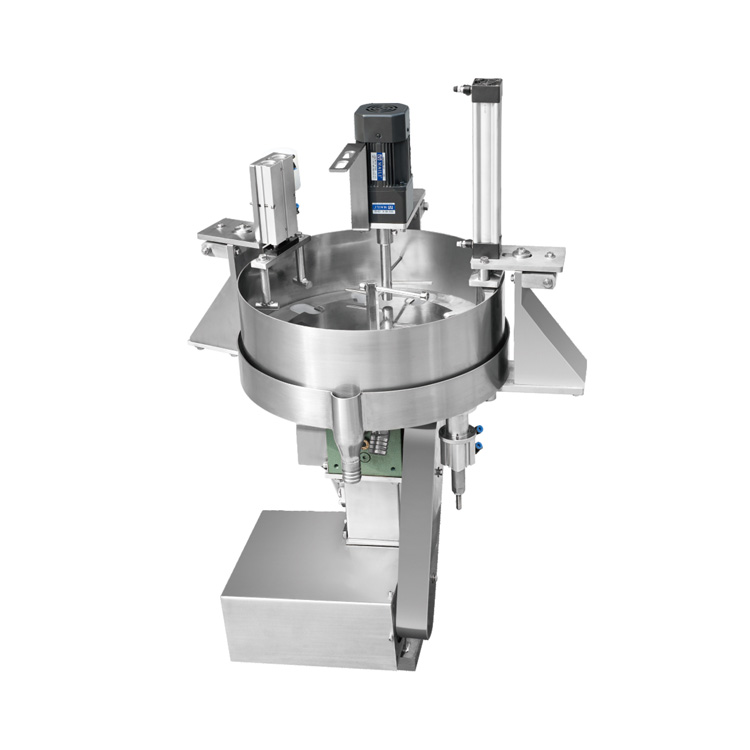

● Mga Tagapuno ng Auger: Idinisenyo para sa mga di-free-flowing o clumpy powder, gamit ang umiikot na turnilyo upang kontrolin ang halagang ibinibigay.

● Mga Vacuum Filler: Angkop para sa mga pulbos na sensitibo sa pagkakalantad sa hangin, na tinitiyak ang isang selyadong, airtight na pakete.

● Mga VFFS (Vertical Form Fill Seal) Machine: Ginagamit para sa high-speed, automated packaging ng mga pulbos sa mga pouch o sachet.

● Mga Tagapuno ng Net Timbang: Gumamit ng mga load cell upang matiyak ang tumpak na pagpuno batay sa timbang para sa mataas na katumpakan sa packaging.

Kapag pumipili ng a powder pouch packing machine, ang mga salik tulad ng katumpakan, bilis, at flexibility ay mahalaga upang ma-optimize ang kahusayan habang pinapanatili ang integridad ng produkto.

Ang katumpakan ay kritikal sa powder packaging machine upang matiyak na ang bawat pakete ay naglalaman ng tamang dami. Ang mga makina na may pinagsamang sistema ng pagtimbang, tulad ng mga net weight filler o auger filler na may mga load cell, ay naghahatid ng tumpak na kontrol, pinapaliit ang mga pamimigay ng produkto at binabawasan ang basura.

Ang bilis ng produksyon ay dapat na tumutugma sa iyong mga kinakailangan sa output. Ang mga high-speed machine, tulad ng twin servo motor VFFS system, ay mainam para sa malalaking operasyon, habang ang mas mabagal na makina ay maaaring angkop para sa mas maliliit na pagpapatakbo ng produksyon. Ang kapasidad ng makina ay dapat tumugma sa iyong mga pangangailangan sa volume upang maiwasan ang mga bottleneck sa proseso ng packaging.

Ang kakayahang umangkop ay mahalaga para sa pag-iimpake ng iba't ibang uri ng mga pulbos o mga format ng packaging. Ang mga makina na nag-aalok ng mabilis na pagbabago ng produkto at mga adjustable na setting ay nagsisiguro ng kaunting downtime at kayang humawak ng iba't ibang katangian ng pulbos, na nagpapahusay sa pangkalahatang kahusayan.

Ang mga linya ng powder packing na hygroscopic o sensitibo sa mga kondisyon ng kapaligiran ay nangangailangan ng espesyal na paghawak upang mapanatili ang kalidad ng produkto at maiwasan ang kontaminasyon sa panahon ng packaging.

Kapag pino ang packaging o mga hygroscopic na pulbos, mahalaga ang pagkontrol ng alikabok upang maiwasan ang kontaminasyon at mapanatili ang kalinisan. Ang mga makina na nilagyan ng mga sistema ng pagkuha ng alikabok o mga lugar na may kasamang pagpuno ay nakakatulong na maiwasan ang pagkalat ng pulbos, na tinitiyak ang isang malinis at ligtas na kapaligiran sa packaging.

Ang mga sensitibong pulbos, lalo na ang mga hygroscopic, ay nangangailangan ng tumpak na kontrol sa temperatura at kahalumigmigan sa panahon ng packaging. Ang mga packaging machine na may pinagsama-samang humidity at mga feature sa pamamahala ng temperatura, tulad ng vacuum sealing o inert gas flushing, ay nagpoprotekta sa mga pulbos mula sa moisture absorption at clumping para mapanatili ang kalidad ng produkto.

Ang pagpili ng tamang mga materyales sa packaging at mga mekanismo ng sealing ay mahalaga para sa pagpapanatili ng integridad ng mga pulbos sa panahon ng pag-iimbak at transportasyon. Tinitiyak ng pagiging tugma na pinoprotektahan ng packaging ang produkto habang nakakatugon sa mga pamantayan ng regulasyon.

การเลือกฟิล์มที่เหมาะสมและ วัสดุบรรจุภัณฑ์มีความสำคัญต่อการรักษาความสดของผลิตภัณฑ์และป้องกันการปนเปื้อน วัสดุทั่วไป ได้แก่ โพลีเอทิลีน (PE) โพลีโพรพีลีน (PP) และฟิล์มลามิเนต ซึ่งมีคุณสมบัติเป็นเกราะป้องกันความชื้น ออกซิเจน และแสง ตัวเลือกขึ้นอยู่กับความไวของผงและสภาวะการเก็บรักษา

▼< %>

ยึดมั่นในการปฏิบัติตามกฎระเบียบและ มาตรฐานอุตสาหกรรมถือเป็นสิ่งสำคัญในการบรรจุผง เครื่องจักร

■ < %%>การปฏิบัติตามข้อกำหนดเกรดอาหารและยา

การรับรองด้านไฟฟ้าและความปลอดภัย < %%>

ในสภาพแวดล้อมที่มีการแข่งขันของบรรจุภัณฑ์ชนิดผง Smart Weigh โดดเด่นในฐานะผู้ผลิตและผู้ให้บริการคุณภาพสูงชั้นนำ

s ด้วยการมุ่งเน้นที่ความแม่นยำและประสิทธิภาพ เครื่องจักรของพวกเขารองรับประเภทผงได้หลากหลาย ทำให้มั่นใจว่าสายการผลิตทำงานได้อย่างราบรื่นในขณะที่ยังคงรักษาความสมบูรณ์ของผลิตภัณฑ์ไว้ ด้วยการใช้ประโยชน์จากเทคโนโลยีขั้นสูง Smart Weigh ช่วยให้ธุรกิจต่างๆ ปรับกระบวนการบรรจุภัณฑ์ให้เหมาะสมเพื่อตอบสนองความต้องการของตลาดปัจจุบัน ข้อเสนอ Smart Weigh โซลูชันต่างๆ ที่ปรับให้เหมาะกับความต้องการเฉพาะ รวมถึงเครื่องถ้วยปริมาตรและเครื่องบรรจุภัณฑ์สว่านโรตารี เครื่องบรรจุผงได้รับการออกแบบมาให้มีประสิทธิภาพสูง ในขณะที่เครื่องบรรจุผงซักผ้าแบบถ้วยปริมาตรเชิงพาณิชย์แบบอัตโนมัติช่วยให้มั่นใจได้ถึงการแบ่งส่วนผงต่างๆ อย่างแม่นยำ นอกจากนี้ เครื่องบรรจุถุงซิปแป้งสว่านโรตารี่แบบอัตโนมัติแปดตำแหน่งยังเป็นแบบอย่างของนวัตกรรมในการจัดการผงประเภทต่างๆ..โดย การเลือก Smart Weigh ธุรกิจสามารถคาดหวังได้ไม่เพียงแต่เทคโนโลยีล้ำสมัยเท่านั้น แต่ยังรวมถึงความมุ่งมั่นในการปฏิบัติตามกฎระเบียบและมาตรฐานอุตสาหกรรมอีกด้วย เครื่องจักรของพวกเขานำเสนอโซลูชั่นที่เชื่อถือได้ซึ่งช่วยเพิ่มกำลังการผลิตและรักษาคุณภาพสูงสุดในบรรจุภัณฑ์ชนิดผง ทำให้กลายเป็นพันธมิตรที่ทรงคุณค่าในอุตสาหกรรม

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Paano Namin Ito Natutugunan At Tinutukoy ang Global

Kaugnay na Packaging Machinery

Makipag-ugnayan sa amin, maaari ka naming bigyan ng mga propesyonal na solusyon sa turnkey packaging ng pagkain

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | Lahat ng Karapatan ay Nakalaan