Uma kuziwa ekukhetheni umshini wokupakisha oyimpuphu ofanele, ukusebenza kahle, ukunemba, kanye nekhwalithi emisebenzini yokupakisha kufanele kube yinto ehamba phambili. Akukhathalekile ukuthi ubhekene nezimpushana ezinhle, eziyimbudumbudu, noma ezinamathelayo, umshini kufanele uhambisane nezici ezithile zokugeleza zomkhiqizo kanye nezidingo zokupakisha. Ngakho-ke, awukwazi ukungazinaki izici ezifana nesivinini, uhlobo lokuvalwa, kanye nokunemba kwengxenye lapho ukhetha imishini yempuphu neyokupakisha.

Ngokuthuthuka kwe-automation, imishini yokupakisha i-powder inikezela ngezinto ezahlukahlukene, kufaka phakathi ama-volumetric fillers, ama-auger fillers, nokuvala uphawu kwe-vacuum ukuthwala izinhlobo ezahlukene zemikhiqizo. Ukuqonda izidingo eziyingqayizivele zempushana yakho, kusukela ekuzweleni komswakama kuya ekuminyana, kubalulekile ekukhetheni umshini ozothuthukisa ukukhiqiza futhi unciphise ukumosha.

Ukukhetha umshini wokupakisha impushana kuncike ezicini zempushana, njengokugeleza, usayizi wezinhlayiyana, kanye nomswakama. Umshini kufanele uqinisekise ukulinganisa okunembile, ukuvala ukufaka umoya, kanye nokuphatha umkhiqizo ngendlela efanele ukuze uhlangabezane nezindinganiso zokupakisha nezokuphepha.

● Izihlungi zeVolumetric: Ilungele izimpushana ezigeleza mahhala, ikala ivolumu yomkhiqizo ngokuhlukaniswa okungaguquki.

● Ama-Auger Fillers: Idizayinelwe okungagelezi mahhala noma ama-clumpy powders, kusetshenziswa isikulufu esizungezayo ukulawula inani elikhishiwe.

● Ama-Vacuum Fillers: Ifanele izimpushana ezizwelayo ekuchayekeni komoya, iqinisekisa iphakheji evaliwe, engenamoya.

● Imishini ye-VFFS (Vertical Form Fill Seal): Isetshenziselwa ukupakisha okunesivinini esikhulu, okuzenzakalelayo kwezimpushana ezikhwameni noma ezikhwameni.

● I-Net Weight Fillers: Sebenzisa amaseli omthwalo ukuze uqinisekise ukugcwaliswa okunembayo okusekelwe esisindweni ukuze kube nokunemba okuphezulu emaphaketheni.

Lapho ukhetha i-a umshini wokupakisha isikhwama se-powder, izici ezifana nokunemba, isivinini, nokuguquguquka kubalulekile ukuze kuthuthukiswe ukusebenza kahle kuyilapho kugcinwa ubuqotho bomkhiqizo.

Ukunemba kubalulekile emshinini wokupakisha oyimpushana ukuqinisekisa ukuthi iphakethe ngalinye linenani elifanele. Imishini enezinhlelo zokukala ezididiyelwe, njengezigcwalisi zesisindo esinetha noma izigcwalisi ze-auger ezinamaseli omthwalo, iletha ukulawula okunembayo, ukunciphisa ukunikezwa komkhiqizo nokunciphisa imfucuza.

Isivinini sokukhiqiza kufanele sihambisane nezidingo zakho zokukhiphayo. Imishini enesivinini esikhulu, njengama-twin servo motor VFFS systems, ilungele ukusebenza ngezinga elikhulu, kuyilapho imishini ehamba kancane ingase ifanelekele ukugijima kokukhiqiza okuncane. Umthamo womshini kufanele uhambisane nezidingo zevolumu yakho ukuze ugweme izingqinamba enqubweni yokupakisha.

Ukuvumelana nezimo kubalulekile ekupakisheni izinhlobo ezahlukene zezimpushana noma amafomethi okupakisha. Imishini ehlinzeka ngokushintsha komkhiqizo okusheshayo nezilungiselelo ezilungisekayo iqinisekisa isikhathi esincane sokuphumula futhi ingakwazi ukuphatha izici ezihlukahlukene zempushana, ithuthukise ukusebenza kahle okuphelele.

Imigqa yokupakisha impushana ene-hygroscopic noma ezwelayo ezimweni zemvelo idinga ukuphathwa okukhethekile ukuze kugcinwe ikhwalithi yomkhiqizo futhi kuvimbele ukungcoliswa ngesikhathi sokupakisha.

Lapho upakisha izimpushana ezinhle noma ze-hygroscopic, ukulawula uthuli kubalulekile ukugwema ukungcoliswa nokugcina inhlanzeko. Imishini efakwe izinhlelo zokukhipha uthuli noma izindawo zokugcwalisa ezivalekile zisiza ukuvimbela ukuhlakazeka kwempushana, iqinisekisa indawo yokupakisha ehlanzekile nephephile.

Izimpushana ezizwelayo, ikakhulukazi eziyi-hygroscopic, zidinga izinga lokushisa elinembile kanye nokulawulwa komswakama ngesikhathi sokupakishwa. Imishini yokupakisha enomswakama odidiyelwe nezici zokulawula izinga lokushisa, njengokuvala ivacuum noma ukushaywa kwegesi engasebenzi, ivikela izimpushana ekumunceni umswakama kanye nokunqwabelana ukuze kugcinwe ikhwalithi yomkhiqizo.

Ukukhetha izinto zokupakisha ezifanele kanye nezindlela zokuvala kubalulekile ekugcineni ubuqotho bezimpushana ngesikhathi sokugcina nokuthutha. Ukuhambisana kuqinisekisa ukuthi iphakheji ivikela umkhiqizo ngenkathi ihlangabezana nezindinganiso zokulawula.

Ukukhetha ifilimu efanele kanye nezinto zokupakisha kubalulekile ukuze kulondolozwe ubusha bomkhiqizo nokuvimbela ukungcoliswa. Izinto ezivamile zifaka i-polyethene (PE), i-polypropylene (PP), namafilimu aminated, ahlinzeka ngezakhiwo zokuvimbela ngokumelene nomswakama, umoya-mpilo, nokukhanya. Okukhethwa kukho kuncike ekuzweleni kwempushana kanye nezimo zokugcina.

Indlela yokuvala idlala indima ebalulekile ekugcineni ubuqotho bephakheji. Izinketho zihlanganisa ukuvala ukushisa, okusebenzisa amandla okushisa ukuze kuhlanganiswe izinto ezisetshenziswayo, nokuvala uphawu okubandayo, okulungele izimpushana ezizwelayo. Indlela yokubeka uphawu enokwethenjelwa iqinisekisa ukuthi ukupakishwa kuhlala kungenamoya, ukuvikela umkhiqizo ezintweni zangaphandle.

Izixazululo zokupakisha ezingaphazamiseki nezingavuzi zibalulekile ekuphepheni nasekuqinisekiseni ikhwalithi. Izici ezinjengokuvalwa kokungeniswa, amafilimu amelana nezinyembezi, namalebula azwela ingcindezi athuthukisa ukuvikeleka, avimbele ukufinyelela okungagunyaziwe futhi aqinisekise ukuthi umkhiqizo uhlala uqukethwe, okunciphisa ingozi yokuchitheka noma ukungcola.

Ukunamathela ekuthotshelweni kokulawula kanye namazinga embonini kubalulekile emshinini wokugcwalisa i-powder, ikakhulukazi emikhakheni yokudla neyokwenza imithi. Le mithethonqubo iqinisekisa ukuphepha komkhiqizo, ikhwalithi, kanye nokulandeleka kulo lonke uchungechunge lokuhlinzeka.

Ekufakweni kwempushana ezimbonini zokudla nezamakhambi, ukuthobela izindinganiso ezifana nemithetho ye-FDA (Food and Drug Administration) kanye ne-GMP (Imikhuba Emihle Yokukhiqiza) kubalulekile. Izinto ezisetshenziswayo kanye nezinto ezisetshenziswayo kumele zenziwe ngezinga lokudla noma ngezinga lezemithi ezingenabo ubuthi futhi ezingenazo izinto ezingcolisayo, eziqinisekisa ukuphepha kanye nekhwalithi yomkhiqizo opakishiwe.

Imishini yokupakisha kufanele futhi ihlangabezane nezitifiketi ezihlukahlukene zikagesi nezokuphepha, ezifana namazinga e-CE, UL, noma ISO. Lezi zitifiketi ziqinisekisa ukuthi okokusebenza kuthobelana nemithetho yezokuphepha, eqinisekisa ukusebenza okuphephile kanye nokunciphisa izingozi zezingozi zikagesi, okubaluleke kakhulu ezindaweni lapho izimpushana zingasha khona noma zibe yingozi yokuphefumula. Ukuhambisana nalawa mazinga kuvikela kokubili abaqhubi kanye nabasebenzisi bokugcina.

Esimeni sokuncintisana sokupakishwa kwempushana, i-Smart Weigh igqama njengomkhiqizi ophambili kanye nomhlinzeki wekhwalithi ephezulu. umshini wokugcwalisa isikhwama se-powders. Ngokugxila ekunembeni nasekusebenzeni kahle, imishini yabo ihlinzeka ngezinhlobo eziningi ze-powder, iqinisekisa ukuthi imigqa yokukhiqiza isebenza kahle ngenkathi igcina ubuqotho bomkhiqizo. Ngokusebenzisa ubuchwepheshe obuthuthukisiwe, i-Smart Weigh isiza amabhizinisi athuthukise izinqubo zawo zokupakisha ukuze ahlangabezane nezidingo zemakethe yanamuhla.

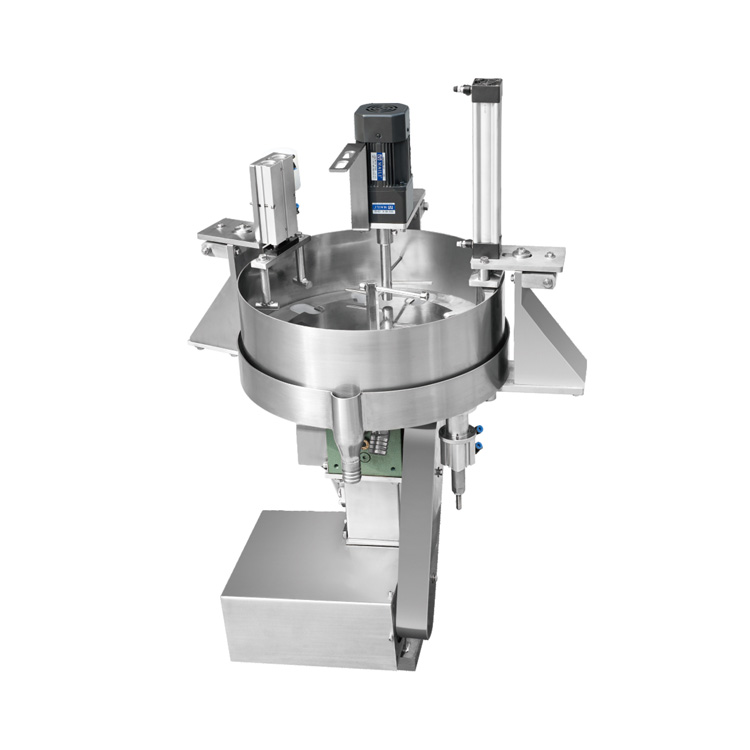

I-Smart Weigh inikeza izixazululo ezihlukahlukene ezihambisana nezidingo ezithile, okuhlanganisa imishini yenkomishi ye-volumetric kanye nemishini yokupakisha ye-rotary auger. Umshini wabo wokupakisha oyimpuphu uklanyelwe ukusebenza kahle okuphezulu, kuyilapho umshini wokupakisha we-volumetric othomathikhi wezohwebo wokulinganisa umshini wokupakisha uqinisekisa ukwahlukaniswa okunembile kwezimpushana ezihlukahlukene. Ukwengeza, umshini wabo wokupakisha wesikhwama se-rotary auger isitashi we-othomathikhi we-rotary auger starch uyisibonelo sokuqamba okusha ekuphatheni izinhlobo zempushana ezahlukahlukene.

Ngokukhetha i-Smart Weigh, amabhizinisi angalindeli nje kuphela ubuchwepheshe obusezingeni eliphezulu kodwa nokuzibophezela ekuthobeleni imithetho nezindinganiso zomkhakha. Imishini yabo inikeza izixazululo ezinokwethenjelwa ezithuthukisa amandla okukhiqiza futhi zigcine izinga eliphezulu kakhulu ekufakweni kwempushana, okubenza babe umlingani obalulekile embonini.

XHUMANA NATHI

Isakhiwo B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Sikwenza Kanjani Ukuhlangana Futhi Sichaze Umhlaba jikelele

Imishini Yokupakisha Ehlobene

Xhumana nathi, singakunikeza izixazululo ze-turnkey zokupakisha ukudla

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | Wonke Amalungelo Agodliwe