Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

When it comes to selecting the right powder packaging machine, efficiency, accuracy, and quality in packaging operations should be the priority. It doesn’t matter if you're dealing with fine, granular, or sticky powders, the machine must be tailored to the product's specific flow characteristics and packaging requirements. Therefore, you cannot overlook factors such as speed, sealing type, and portion accuracy when choosing powder and packaging machines.

With advancements in automation, powder packing machines offer various features, including volumetric fillers, auger fillers, and vacuum sealing to accommodate different product types. Understanding the unique needs of your powder, from moisture sensitivity to density, is crucial in selecting the machine that will optimize production and minimize waste.

Choosing a powder bagging machine depends on the powder's characteristics, such as flowability, particle size, and moisture content. The machine should ensure precise dosing, airtight sealing, and efficient product handling to meet packaging and safety standards.

● Volumetric Fillers: Ideal for free-flowing powders, they measure product volume for consistent portioning.

● Auger Fillers: Designed for non-free-flowing or clumpy powders, using a rotating screw to control the amount dispensed.

● Vacuum Fillers: Suitable for powders sensitive to air exposure, ensuring a sealed, airtight package.

● VFFS (Vertical Form Fill Seal) Machines: Used for high-speed, automated packaging of powders in pouches or sachets.

● Net Weight Fillers: Utilize load cells to ensure precise weight-based filling for high accuracy in packaging.

When selecting a powder pouch packing machine, factors such as accuracy, speed, and flexibility are essential to optimize efficiency while maintaining product integrity.

Accuracy is critical in powder packaging machine to ensure each package contains the correct amount. Machines with integrated weighing systems, such as net weight fillers or auger fillers with load cells, deliver precise control, minimising product giveaways and reducing waste.

Production speed must align with your output requirements. High-speed machines, like twin servo motor VFFS systems, are ideal for large-scale operations, while slower machines may be suitable for smaller production runs. The machine's capacity should match your volume needs to avoid bottlenecks in the packaging process.

Flexibility is important for packaging different types of powders or packaging formats. Machines that offer quick product changeovers and adjustable settings ensure minimal downtime and can handle a variety of powder characteristics, improving overall efficiency.

Powder packing lines that are hygroscopic or sensitive to environmental conditions require special handling to maintain product quality and prevent contamination during packaging.

When packaging fine or hygroscopic powders, dust control is essential to avoid contamination and maintain cleanliness. Machines equipped with dust extraction systems or enclosed filling areas help prevent powder dispersion, ensuring a clean and safe packaging environment.

Sensitive powders, especially hygroscopic ones, need precise temperature and moisture control during packaging. Packaging machines with integrated humidity and temperature management features, like vacuum sealing or inert gas flushing, protect powders from moisture absorption and clumping to preserve product quality.

Choosing the right packaging materials and sealing mechanisms is crucial for maintaining the integrity of powders during storage and transportation. Compatibility ensures that the packaging protects the product while meeting regulatory standards.

Selecting appropriate film and packaging materials is vital for preserving product freshness and preventing contamination. Common materials include polyethene (PE), polypropylene (PP), and laminated films, which provide barrier properties against moisture, oxygen, and light. The choice depends on the powder's sensitivity and storage conditions.

The sealing mechanism plays a critical role in maintaining package integrity. Options include heat sealing, which uses thermal energy to bond materials, and cold sealing, ideal for sensitive powders. A reliable sealing method ensures that the packaging remains airtight, protecting the product from external factors.

Tamper-proof and leak-proof packaging solutions are essential for safety and quality assurance. Features such as induction sealing, tear-resistant films, and pressure-sensitive labels enhance security, preventing unauthorised access and ensuring that the product remains contained, reducing the risk of spills or contamination.

Adhering to regulatory compliance and industry standards is essential in powder filling machine, particularly in the food and pharmaceutical sectors. These regulations ensure product safety, quality, and traceability throughout the supply chain.

For powder packaging in the food and pharmaceutical industries, compliance with standards such as FDA (Food and Drug Administration) regulations and GMP (Good Manufacturing Practices) is crucial. Equipment and materials must be made from food-grade or pharmaceutical-grade materials that are non-toxic and free from contaminants, ensuring the safety and quality of the packaged product.

Packaging machines must also meet various electrical and safety certifications, such as CE, UL, or ISO standards. These certifications verify that the equipment complies with safety regulations, ensuring safe operation and reducing risks of electrical hazards, which is particularly important in environments where powders can be flammable or pose respiratory risks. Compliance with these standards protects both operators and end-users.

In the competitive landscape of powder packaging, Smart Weigh stands out as a premier manufacturer and provider of high-quality powder pouch filling machines. With a focus on precision and efficiency, their machines cater to a wide range of powder types, ensuring that production lines operate smoothly while maintaining product integrity. By leveraging advanced technology, Smart Weigh helps businesses optimize their packaging processes to meet the demands of today's market.

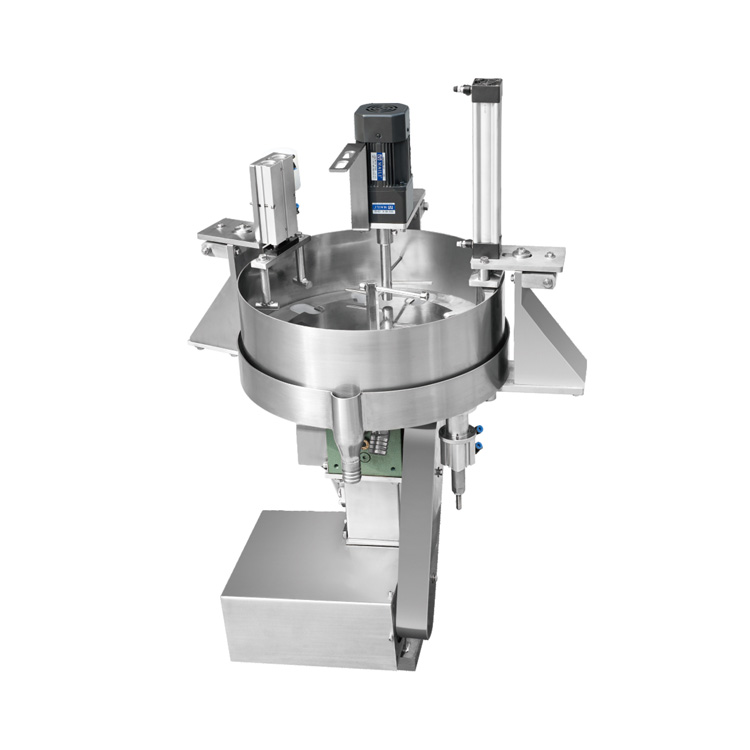

Smart Weigh offers various solutions tailored to specific needs, including volumetric cup machines and rotary auger packaging machines. Their powder packing machine is designed for high efficiency, while the automatic commercial volumetric cup measuring washing powder packaging machine ensures accurate portioning for various powders. Additionally, their automatic eight position rotary auger starch flour zipper bag packaging machine exemplifies innovation in handling diverse powder types..

By choosing Smart Weigh, businesses can expect not only cutting-edge technology but also a commitment to regulatory compliance and industry standards. Their machines provide reliable solutions that enhance production capacity and maintain the highest quality in powder packaging, making them an invaluable partner in the industry.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved