Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

automatic chocolate candy jelly stick packing machine

| NAME | SW-P420 vertical packaging machine |

| Capacity | ≤70 Bags/min according to products and film |

| Bag size | Bag Width 50-200mm Bag Length 50-300mm |

| Film width | 120-420mm |

| Bag type | Pillow Bags, Gusset Bags,Linking bags, side ironed bags as "three squareels" |

| Diameter of Film Roll | ≤420mm larger than standard type VP42, so no need to change film roller that often |

| Film thickness | 0.04-0.09mm Or customized |

| Film material | BOPP/VMCPP,PET/PE,BOPP/CPP, PET/AL/PE etc |

| Diameter of Film Roll Inner Core | 75mm |

| Total power | 2.2KW 220V 50/60HZ |

| Food Contact | All food contact parts are SUS 304 90% of whole machine are stainless steel |

| Net Weight | 520kg |

1. New exterior appearance and combined type of frame are made the machine become more precision on the whole

2. Same appearance of our high speed machine

3. Over 85% spare parts are stainless steel, all the film going frame is 304 stainless steel

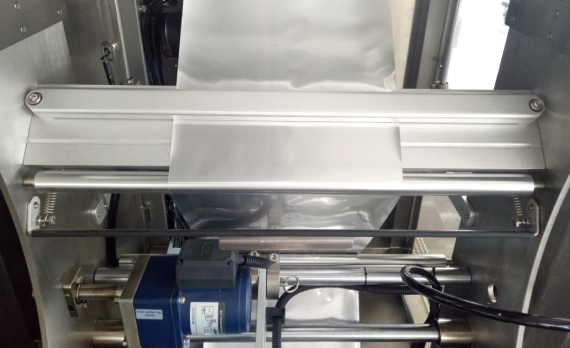

4. Longer film pulling belts, more stable

5. Vertical structure is easier to adjust, stable

6. Longer rack of film axis, to avoid damages of film

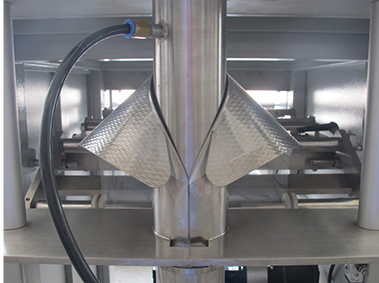

7. Bag former newly designed, which is the same with high speed machine, and easy to change by just release one screw bar.

8. Larger film roller up to diameter 450mm, to save the frequency of change another film

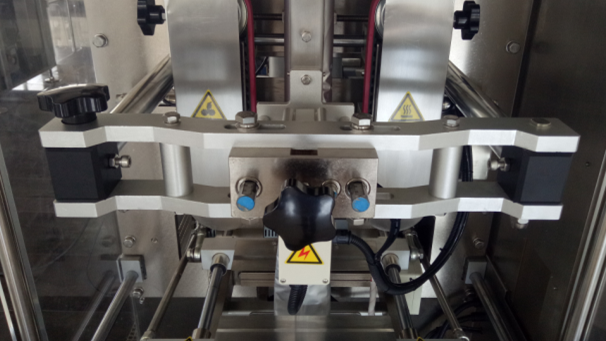

9. Electric box is easy to move, open and maintenance freely

10.Touch screen is easy to move, machine working with lower noise

Add cylinder film clip structure to make easier to change film rolls and connecting easily in horizontal and vertical accurate positioning.

Bag former design updated, easy to change just by relaxing the plum blossom handle.So easy to change bag formers just in 2 minutes!

When matching this baopack new version VP42A with different measuring system, it can pack powder, granule, liquid etc. Mainly into pillow bags, gusset bags, also optionally linking bags, punching holes bags for different ways to exhibit better in showshelves. Hope we can help from the beginning to lifetime project.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved