Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Over the years, Smart Weigh has been offering customers high-quality products and efficient after-sales services with the aim of bringing unlimited benefits for them. automated packaging solutions We promise that we provide every customer with high-quality products including automated packaging solutions and comprehensive services. If you want to know more details, we are glad to tell you. has dedicated years to innovating and manufacturing automated packaging solutions. Our technical prowess and state-of-the-art equipment coupled with strict production management and quality inspection systems ensure that the automated packaging solutions quality of production remains consistently high. Trust in our expertise to deliver exceptional automated packaging solutions.

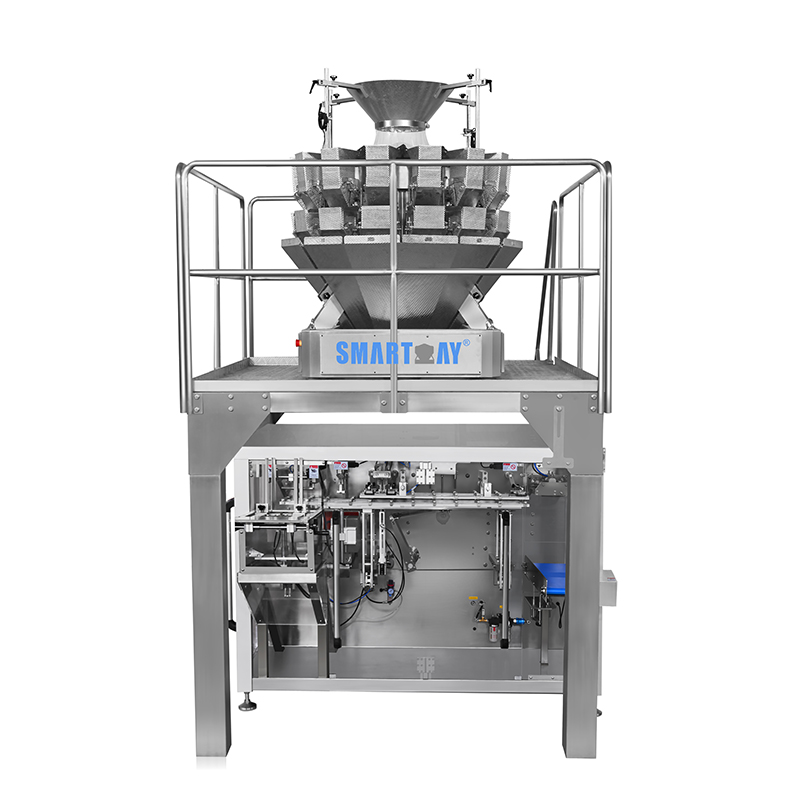

Chin chin packaging machines are one of packing machine for snacks food, the same packaging machine can be used for potato chips, banana chips, jerky, dry fruits, candies and other food.

Weighing Range | 10-1000 grams |

Max Speed | 10-35 bags/min |

Bag Style | Stand-up, pouch, spout, flat |

Bag Size | Length: 150- 350mm |

Bag Material | Laminated film |

Accuracy | ±0.1-1.5 grams |

Film Thickness | 0.04-0.09 mm |

Working Station | 4 or 8 station |

Air Consumption | 0.8 Mps, 0.4m3/min |

Driving System | Step Motor for scale, PLC for packing machine |

Control Penal | 7" or 9.7 " Touch Screen |

Power Supply | 220V/50 Hz or 60 Hz, 18A, 3.5KW |

Smaller machine volume and space compared with standard rotary pouch packing machine;

Stable packing speed 35 packs/min for standard doypack, higher speed for smaller size of pouches;

Fit for different bag size, quick set while change new bag size;

High hygienic design with stainless steel 304 materials.

The buyers of automated packaging solutions come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. automated packaging solutions QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

Yes, if asked, we will supply relevant technical details regarding Smart Weigh. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

Smart Weigh Packaging Machinery Co., Ltd. always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

In essence, a long-standing automated packaging solutions organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved