Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Set up years ago, Smart Weigh is a professional manufacturer and also a supplier with strong capabilities in production, design, and R&D. automated packing system Today, Smart Weigh ranks the top as a professional and experienced supplier in the industry. We can design, develop, manufacture, and sell different series of products on our own combining the efforts and wisdom of all our staff. Also, we are responsible for offering a wide range of services for customers including technical support and prompt Q&A services. You may discover more about our new product automated packing system and our company by directly contacting us.The product operates nearly with no noise during the entire dehydration process. The design enables the whole body of the product to stay balanced and stable.

Suitable for weighing and packaging granular materials, such as pasta, macaroni, potato chips, cereal, biscuits, nuts, rice, seeds, tablets, etc. The packaging bag types are pillow bag, pillow bag with gusset.

Pasta Packaging Machine Macaroni VFFS Packaging Machine with Multihead Weigher for Food

²Full automatic from feeding to finished products outputting

²Multihead weigher will automatic weigh according to preset weight

²Preset weight products drop into bag former, then packing film will be formed and sealed

²All food contact parts can be took out without tools, easy cleaning after daily work

Model | SW-PL1 |

Weighing Range | 10-5000 grams |

Bag Size | 120-400mm(L) ; 120-400mm(W) |

Bag Style | Pillow Bag; Gusset Bag; Four side seal |

Bag Material | Laminated film; Mono PE film |

Film Thickness | 0.04-0.09mm |

Speed | 20-100 bags/min |

Accuracy | + 0.1-1.5 grams |

Weigh Bucket | 1.6L or 2.5L |

Control Penal | 7" or 10.4" Touch Screen |

Air Consumption | 0.8Mps 0.4m3/min |

Power Supply | 220V/50HZ or 60HZ; 18A; 3500W |

Driving System | Stepper Motor for scale; Servo Motor for bagging |

Multihead Weigher

² IP65 waterproof

² PC monitor production data

² Modular driving system stable & convenient for service

² 4 base frame keep machine running stable & high precision

² Hopper material : dimple( sticky product) and plain option( free flowing product)

² Electronic boards exchangeable between different model

² Load cell or photo sensor checking are available for different products

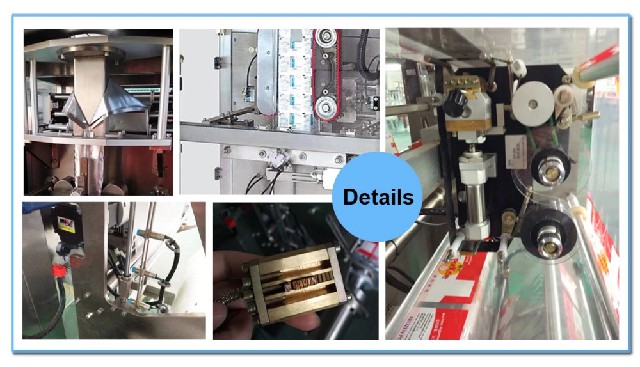

Vertical Packing Machine

²Film auto centering while running

²Air lock film easy for loading new film

²Free production and EXP date printer

²Customize function & design can be offered

²Strong frame ensure running stable everyday

²Lock door alarm and stop running ensure safety operation

Model | SW-B1 |

Convey height | 1800-4500 mm |

Bucket volume | 1.8Lor4.0L |

Carrying speed | 40-75 buckets/min |

Bucket material | White PP (dimple surface) |

Voltage | 220V/50HZ or 60HZ.single phase |

üWhole frame made by mold, more stable compare with chain conveyor.

SW-B2 Incline elevator

Model | SW-B2 |

Convey height | 1800-4500 mm |

Bet width | 220- 400 mm |

Carrying speed | 40-75 cell/min |

Bucket material | White PP (food grade) |

Voltage | 220V/50HZ or 60HZ, single phase |

üCan be washed down by water

üWidely used in salad, vegetable and fruit.

SW-B1 Compact working platform

üStable and safe with guardrail and ladder

üMaterial: SUS304 or carbon steel

üStandard size: 1.9(L) x 1.9(W) x 1.8(H) Customized size is acceptable.

SW-B4 Output conveyor

üWith converter, speed adjustable

üMaterial: SUS304 or carbon steel

üMade by mold

üHeight 1.2-1.5m, belt width: 400 mm

SW-B5 Rotary collect table

üTwo choices

üMaterial: SUS304

üHeight: 730+50mm.

üDiameter. 1000mm

Smart Weigh Packaging Machinery is dedicated in completed weighing and packaging solutions for the food packing industry. We are an integrated manufacturer of R&D, manufacturing, marketing and providing after-sale service. We are focusing on auto weighing and packing machines for snack food, agricultural products, fresh produce, frozen food, ready food, hardware plastic and etc.

1. How can you meet our requirements and needs well?

We will recommend the suitable model of machine and make the unique design based on your project details and requirements.

2. Are you manufacturer or trading company?

We are manufacturer; we are specializing in packing machine line for many years.

3. What about your payment?

² T/T by bank account directly

² Trade assurance service on Alibaba

² L/C at sight

4. How can we check your machine qualityafter we place an order?

We will send the photos and videos of the machine to you to check their running situation before delivery. What’s more, welcome to come to our factory to check the machine by you own

5. How can you ensure you will send us the machine after the balance paid?

We are a factory with business license and certificate. If that is not enough, we can make the deal through trade assurance service on Alibaba or L/C payment to guarantee your money.

6. Why we should choose you?

² Professional team 24 hours provide service for you

² 15 months warranty

² Old machine parts can be replaced no matter how long you have bought our machine

² Oversea service is provided.

Regarding the attributes and functionality of the automated packing system, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

In China, ordinary working time is 40 hours for employees who work full time. In Smart Weigh Packaging Machinery Co., Ltd., most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Packing Machine and an unforgettable experience of partnering with us.

In essence, a long-standing automated packing system organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Regarding the attributes and functionality of the automated packing system, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. automated packing system QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved