Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Smart Weigh has developed to be a professional manufacturer and reliable supplier of high-quality products. Throughout the whole production process, we strictly implement the ISO quality management system control. Since established, we always adhere to independent innovation, scientific management, and continuous improvement, and provide high-quality services to meet and even exceed customers' requirements. We guarantee our new product automatic bagging system will bring you a lot of benefits. We are always standby to receive your inquiry. automatic bagging system We promise that we provide every customer with high-quality products including automatic bagging system and comprehensive services. If you want to know more details, we are glad to tell you.The components and parts of Smart Weigh are guaranteed to meet the food grade standard by the suppliers. These suppliers have been working with us for years and they attach much attention to quality and food safety.

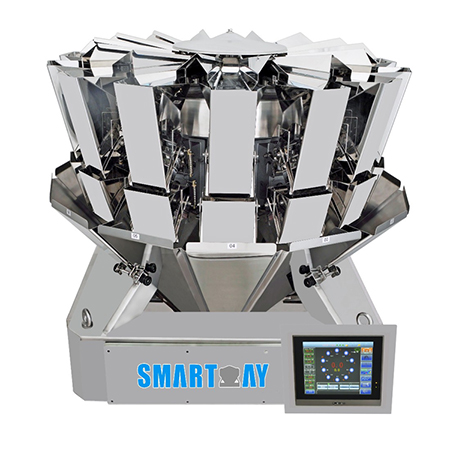

PRODUCT DISPLAY

PRODUCT DESCRIPTION

Model | SW-PL1 |

System | Multihead weigher vertical packing system |

Application | Granular product |

Weigh range | 10-1000g (10 head); 10-2000g (14 head) |

Accuracy | ±0.1-1.5 g |

Speed | 30-50 bags/min (normal) 50-70 bags/min (twin servo) 70-120 bags/min (continuous sealing) |

Bag size | Width=50-500mm, length=80-800mm (Depends on packing machine model) |

Bag style | Pillow bag, gusset bag, quad-sealed bag |

Packaging materials | Laminated or PE film |

Weighing method | Load cell |

Control penal | 7” or 10” touch screen |

Power supply | 5.95 KW |

Air consumption | 1.5m3/min |

Voltage | 220V/50HZ or 60HZ, single phase |

Packing size | 20” or 40” container |

PRODUCT FEATURES

Application:

It is mainly apply in automatic weighing various granular products in food or non-food industries, such as potato chips, nuts, frozen food, vegetables, seafood, nail and etc.

Features:

- Max speed 120 bags/min for small weight chips;

- IP 65 waterproof rating, can washed by water directly, save time while cleaning;

- Modular control system, more stability and lower maintenance fees;

- Production records can be checked at anytime or download to PC;

- Loadcell or photo sensor checking to satisfy different requirements;

- Preset stager dump function to stop blockage;

- Design linear feeder pan deeply to stop small granule products leaking out;

- Refer to product features, select automatic or manual adjust feeding amplitude;

- Food contact parts disassembling without tools, which is easier to clean;

- Multi-languages touch screen for various clients, English, French, Spanish, etc.

- SIEMENS PLC control system, more stable and accuracy output signal, bag-making, measuring, filling, printing, cutting, finished in one operation;

-

- Separate circuit boxes for pneumatic and power control. Low noise and more stable;

- Film pulling with servo motor for precision, pulling belt with cover to protect moisture;

- Open door alarm and stop machine running in an condition for safety regulation;

- Film centering automatically is available (Optional);

- Only control touch screen to adjust bag deviation. Simple operation;

- Film in roller can be locked and unlocked by air, convenient while change film.

COMPANY PROFILE

Smart Weigh Packaging Machinery is dedicated in completed weighing and packaging solution for foods packing industry. We are an integrated manufacturer of R&D, manufacturing, marketing and providing after-sale service. We are focusing on auto weighing and packing machine for snack food, agricultural products, fresh produce, frozen food, ready food, hardware plastic and etc.

FAQ

1. How can you meet our requirements and needs well?

We will recommend the suitable model of the machine and make a unique design based on your project details and requirements.

2. Are you a manufacturer or trading company?

We are a manufacturer; we are specializing in packing machine line for many years.

3. How can we check your machine quality after we place an order?

We will send the photos and videos of the machine to you to check their running situation before delivery. What’s more, welcome to come to our factory to check the machine on your own

4. How can you ensure you will send us the machine after the balance paid?

We are a factory with a business license and certificate. If that is not enough, we can make the deal through trade assurance service on Alibaba or L/C payment to guarantee your money.

6. Why we should choose you?

—Professional team 24 hours provide service for you

—15 months warranty

—Old machine parts can be replaced no matter how long you have bought our machine

—Oversea service is provided.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved