Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Always striving toward excellence, Smart Weigh has developed to be a market-driven and customer-oriented enterprise. We focus on strengthening the capabilities of scientific research and completing service businesses. We have set up a customer service department to better provide customers with prompt services including order tracking notice. can filling line Smart Weigh have a group of service professionals who are responsible for answering questions raised by customers through the Internet or phone, tracking the logistics status, and helping customers solve any problem. Whether you'd like to get more info on what, why and how we do, try our new product - Cost-effective can filling line company, or would like to partner up, we'd love to hear from you.Smart Weigh is designed with a thermostat which is certified under CE and RoHS. The thermostat has been inspected and tested to guarantee its parameters is accurate.

Tin can packaging has been a staple in the food and beverage industry for decades. It's a method that has stood the test of time, providing a durable and cost-effective way for various food preservation and transport. With the advent of modern technology, tin can packaging machines have taken this traditional method to new heights, offering efficiency, precision, and sustainability. It has became a wise invest for food processors.

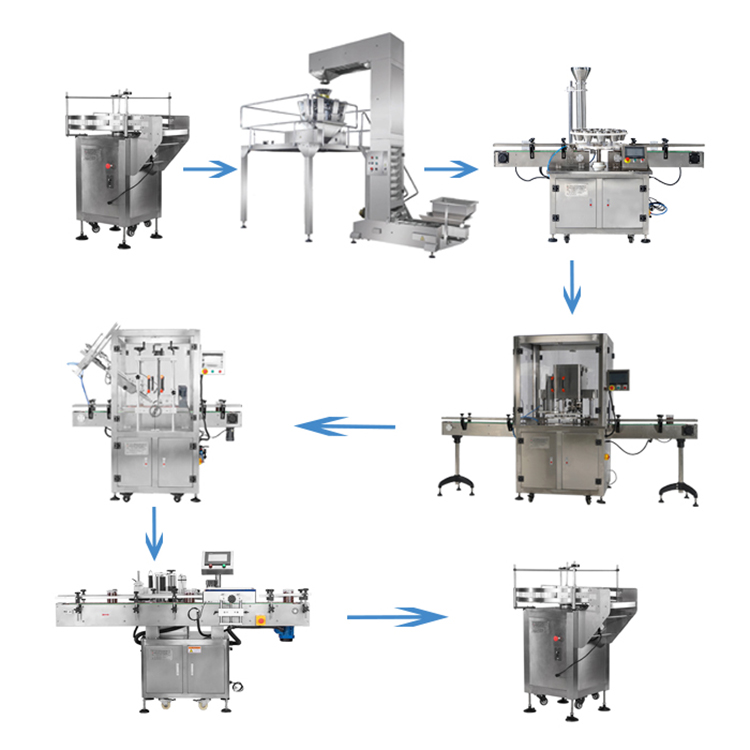

At Smart Weigh, we are not only provide the single automatic tin can sealing machine or can labelling machines, but also offer the complete solution for different types metal tin cans. Let's take a look at how many machines the tin can packing line consists of:

*

* Feed conveyor delivers bulk products to multihead weigher, then multihead scale start to weigh and fill. Our multi head weigher features:

* IP65 waterproof, use water cleaning directly, save time while cleaning;

* Modular control system, more stability and lower maintenance fees;

* Production records can be checked at anytime or download to PC;

* Load cell or photo sensor checking to satisfy different requirements;

* Food contact parts disassembling without tools, which is easier to clean;

* Multi-languages touch screen for various clients, English, French, Spanish, etc.

This device is installed under the multihead weigher, it is used for deliver and locate the empty tin cans which is ready for filling. For small materials at the mouth of the tank, the filling rotary table has multiple stations to buffer and synchronously vibrate when feeding, which can increase the filling speed and prevent material blocking.

* Filling diameter φ40 ~ φ130mm, applicable height 50 ~ 200mm (customized according to jar size)

* Production efficiency is about 30-50 cans per minute;

* The overall appearance material is mainly made of stainless steel 304 with a thickness of 1.5mm;

* The chuck and hopper need to be replaced to change the feeding diameter, and the replacement and debugging time is about 10 minutes;

* Change the jar height, no need to change the accessories, just shake the hand wheel, the range is controlled from 50-200mm, and the adjustment time is about 5 minutes;

* Control panel: 7-inch LCD display.

Can seaming machine, also known as a can sealer, is a piece of industrial equipment used to seal the foil lid of a can to its body. It ensures that the contents of the can are kept airtight and free from contamination, optional for Special nitrogen flush.

* High volume Fully-automatic single head seam;

* Adjustable production capacity,seam Up to 50 cans/minute;

* Perfect for sealing tin, aluminum, PET or other paper cans with a maximum diameter of 130mm;

* 2 or 4 seaming rollers for consistent & leak-proof seam.

A lid capping machine, known simply as a capping machine, is a device used in various industries to apply and secure plastic caps or lids onto containers such as bottles, jars, cans.

* It can loading lots of lids and auto separate one by one for capping onto the top of can;

* Custmized design for different kind of lids;

* 7' Touch screen & Mitsubishi control system for more stable running;

* Stainless steel 304 frame suitable for food grade industries.

It applies to labeling of various round bottles that can not stand up. Such as: oral liquid bottles, ampoules, syringes bottles, batteries, ham, sausage, test tubes, pen, lipstick, solid plastic bottles.

* Main body is made by SUS304 stainless steel & processing by anode of aluminum metal.

* Touch screen control panel, easy operating, included 50-suite memory unit.

* Can configure code printer, accomplishing function of labeling and coding at the same time.

In conclusion, the Automatic Tin Can Packaging Machine from Smart Weigh represents a comprehensive solution for the food industry, encompassing every stage of the packaging process. From the efficient feeding conveyor to the precise multihead weigher, the innovative rotary type can feeder, the airtight seaming machine, the versatile lid capping machine, the meticulous labeling machine, and the final collecting machine, this system offers unparalleled efficiency, precision, and quality control.

If you're looking to elevate your packaging line, reduce costs, and ensure the highest standards of quality and sustainability, Smart Weigh's Tin Can Packing Machine is the solution you've been searching for. Don't miss the opportunity to transform your production line with this high-tech system. Contact us now to learn more and take the first step towards a more efficient and profitable future.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. can filling line QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Yes, if asked, we will supply relevant technical details regarding Smart Weigh. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

In essence, a long-standing can filling line organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

The buyers of can filling line come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

Regarding the attributes and functionality of the can filling line, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved