Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Always striving toward excellence, Smart Weigh has developed to be a market-driven and customer-oriented enterprise. We focus on strengthening the capabilities of scientific research and completing service businesses. We have set up a customer service department to better provide customers with prompt services including order tracking notice. food tray packaging machine Smart Weigh is a comprehensive manufacturer and supplier of high-quality products and one-stop service. We will, as always, actively provide prompt services such. For more details about our food tray packaging machine and other products, just let us know.food tray packaging machine It is made of food-grade stainless steel, with fine workmanship, beautiful shape, smooth and bright surface, and it will last forever after long-term use.

The auto sealing and packing process is the main emphasis of the ready meal packaging machine on the market. As a ready to eat food packaging machine manufacturer, Smart Weigh offers comprehensive solutions for feeding, weighing, filling, packing, and sealing. We design and project manage the installation of entire ready meal packing machine lines, delivering automated full-line solutions that are flexible enough to meet your business needs and respond to changing markets.

| Name | Automatic Ready To Eat Food Packaging Machine |

| Capacity | 1000-1500 Trays/Hour |

| Filling volume | 50-500ML |

| Size | 2600mm×1000mm×1800mm / Customized |

| Weight | 600KG / Customized |

| Power | 5KW / Customized |

| Control | PLC |

| Sealing Type | Al-foil film / roll film |

| Air Consumption | 0.6 m3/min |

| The meal packaging machine can be Customized according to your Requirements. | |

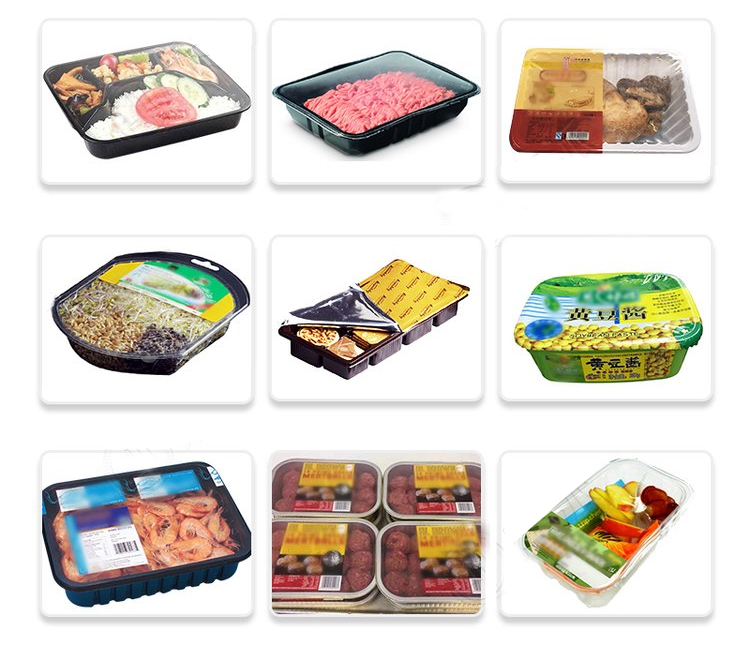

The ready meal packaging machine can be customized for all kinds of fastfood cook meals in tray, vegetable tray, sandwich tray, tofu tray and other container related food packing. It can automatic cup dropping(according to tray), filling(optional), roll film sealing, two side sealing, straight cutting, cup exiting. The ready to eat food packaging machine use Japan Omron programmable logic controller, CIP auto matic Cleaning Barrel, Taiwan pneumatic control components, Intelligent Digital Display Temperature Control System, seaing with high strength, good sealing, and low failure rate.

.

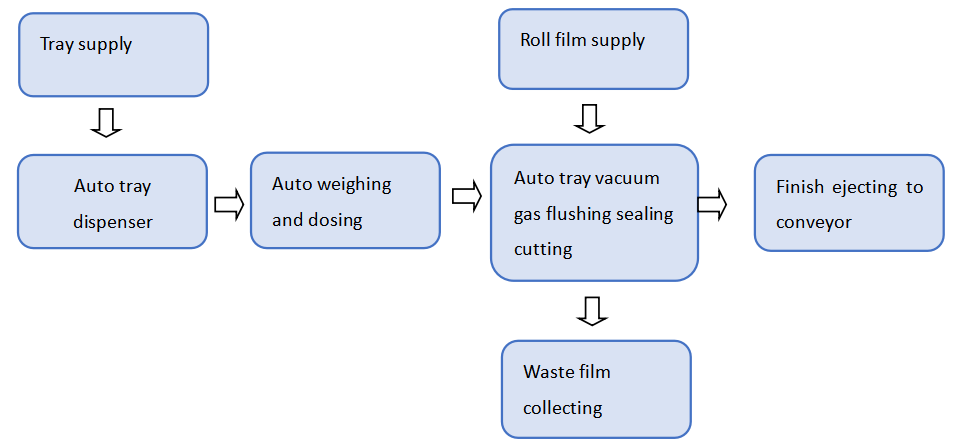

Fully automatic linear tray filling sealing machine can auto loading the empty trays, empty trays detecting, auto quantitative filling product into tray, automatic film pulling and waste collecting, auto tray vacuum gas flushing, sealing and film cutting,auto ejecting the finish product to conveyor. Its capacity 1000-1500trays per hour, suitable for the foods factory production needs. Less time and less labour for the same capacity. These systems are specifically designed to be integrated into automated production lines and can continuously form, fill, seal and label a variety of prepared food products. From frozen dinners and instant noodles to snack packs, ready-to-eat machines accommodate different food packaging styles such as plastic films, trays and boxes.

In order to meet the diverse packaging needs of the ready to eat meal packaging industry, Smart Weigh has various types of packaging machines to choose from. These machines are designed to handle different packaging formats, materials and production requirements. Some common types of meal packing machine include: gas flush modified atmosphere machine, vacuum tray sealing machine, and thermoforming packaging machines etc.

Vacuum gas flushing sealing cutting device

Vacuum gas flushing sealing cutting device

Tray dispenser

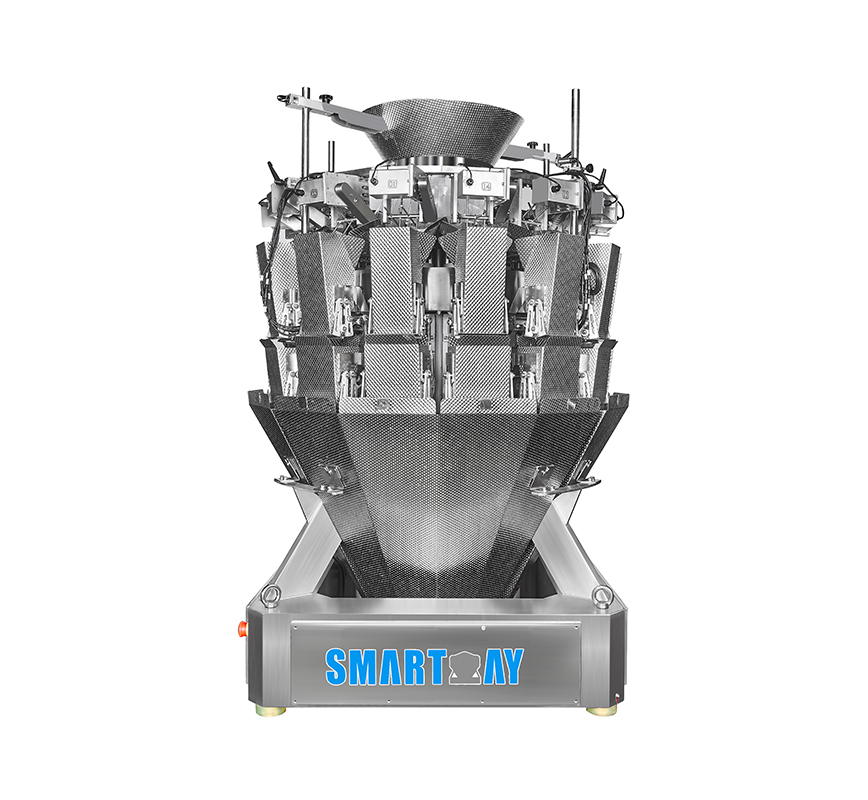

Multihead Weigher Ready Meal Packing Machine

Samples:

It is widely applicable to trays of various sizes and shapes. The following is part of the packaging effect show

The buyers of food tray packaging machine come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. food tray packaging machine QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Regarding the attributes and functionality of the food tray packaging machine, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Regarding the attributes and functionality of the food tray packaging machine, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Yes, if asked, we will supply relevant technical details regarding Smart Weigh. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved