Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Smart Weigh has developed to be a professional manufacturer and reliable supplier of high-quality products. Throughout the whole production process, we strictly implement the ISO quality management system control. Since established, we always adhere to independent innovation, scientific management, and continuous improvement, and provide high-quality services to meet and even exceed customers' requirements. We guarantee our new product form fill and seal machine manufacturers will bring you a lot of benefits. We are always standby to receive your inquiry. form fill and seal machine manufacturers Smart Weigh is a comprehensive manufacturer and supplier of high-quality products and one-stop service. We will, as always, actively provide prompt services such. For more details about our form fill and seal machine manufacturers and other products, just let us know. possesses impressive technical expertise, extensive production experience, and top-of-the-line production equipment. Expect no less from the form fill and seal machine manufacturers it creates - superior performance, consistent quality, and unparalleled excellence. Every product is certified by the national authority for quality assurance. Experience the best there is, only from .

Automatic sugar packing rice bean sugar forming filling packing machine

1. PLC control with stable reliable biaxial high accuracy output and color touch screen, bag-making, measuring, filling, printing,cutting , finished in one operation.

2. Separate circuit boxes for pneumatic control and power control. Noise is low, and the circuit is more stable.

3. Film-pulling with servo motor double belt: less pulling resistance, bag is formed in good shape with better appearance, belt is resistant to be worn-out.

4. External film releasing mechanism: simpler and easier installation of packing film.

5. Adjustment of bag deviation just needed to be controlled by the touch screen. Operation is very simple .

6. Close down type mechanism , defending powder into inside of machine.

Suitable for packaging many different kinds of products; such as puffy food, shrimp roll, peanut, popcorn, cornmeal, dried fruit, seed, small hardware,dumplings, vegetable, fruits and sugar etc.which shape is roll, slice and granule.

Automatic filling and sealing together .

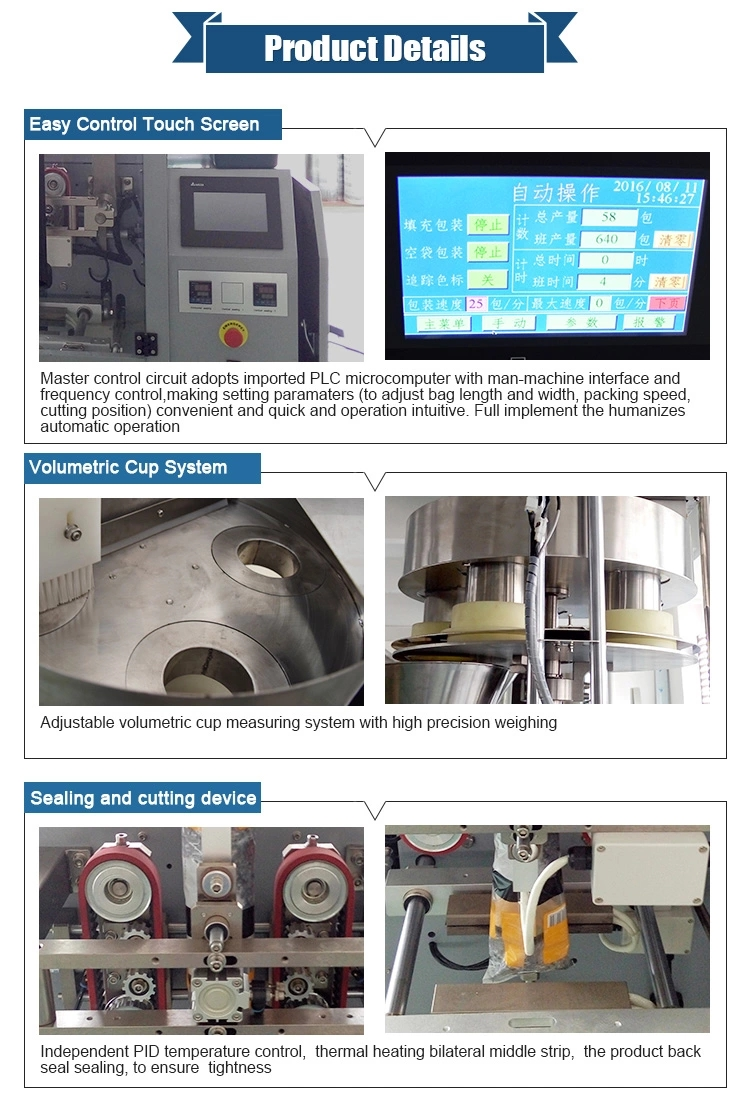

Master control circuit adopts imported PLC microcomputer with man-machine interface andfrequency control,making setting paramaters (to adjust bag length and width, packing speed,cutting position) convenient and quick and operation intuitive. Full implement the humanizesautomatic operation

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved