Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Set up years ago, Smart Weigh is a professional manufacturer and also a supplier with strong capabilities in production, design, and R&D. manual powder filling machine We have been investing a lot in the product R&D, which turns out to be effective that we have developed manual powder filling machine. Relying on our innovative and hard-working staff, we guarantee that we offer customers the best products, the most favorable prices, and the most comprehensive services as well. Welcome to contact us if you have any questions.People find it really useful to dry fresh fruit, meat, chili, as well as to re-dehydrate their shrimp chips and french fries if they get moistened.

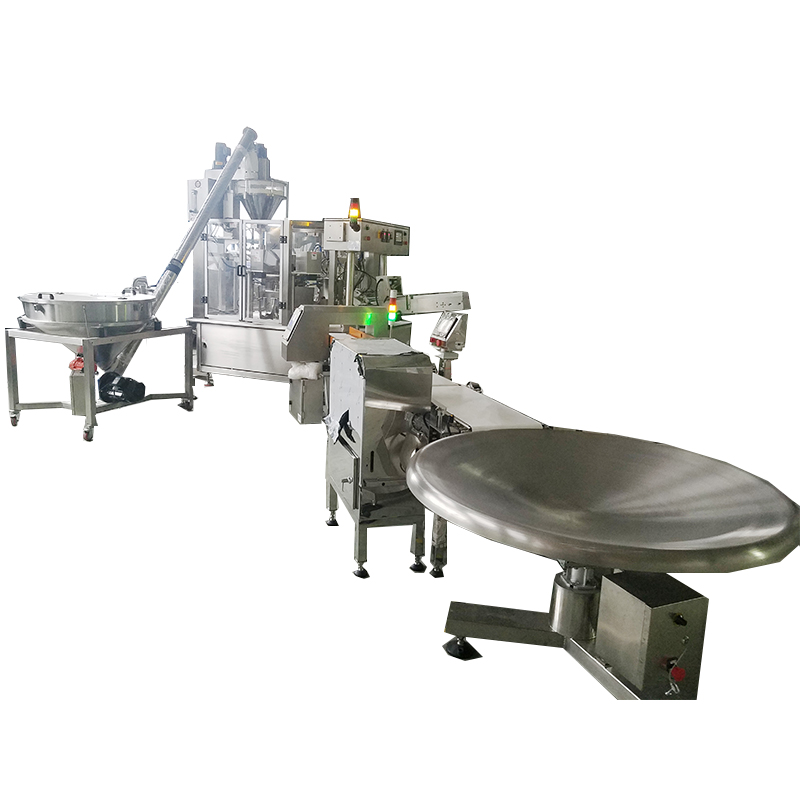

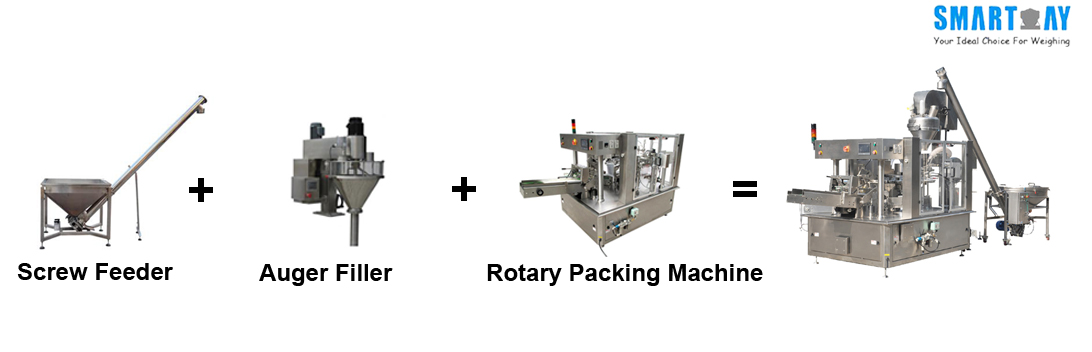

Powder pouch packing machine can automatically and quickly pack a variety of powder products, such as chili powder, coffee powder, milk powder, matcha powder, soybean powder, starch, wheat flour, sesame powder, protein powder, etc. Here we mainly introduce the powder pouch filling machine with auger filler and screw feeder. The closed design can effectively avoid powder leakage and reduce dust pollution. Auger filler can prevent the powder from sticking, improve the fluidity of the material, and make the powder finer and smoother through high-speed rotary stirring. You can choose a suitable powder packaging machine according to the characteristics of materials and packaging bags. Smart Weigh can recommend suitable packaging machines according to customer needs (bag style, bag size, material weight, precision requirements, etc.). In addition, we can provide customized services according to your specific requirements.

l 2 types of Rotary Premade Bag Powder Filling Machine

l The structure of premade pouch packing machine for powder

l Features & benefits of spice pouch packing machine

l Machine Specifications

l What are the factors that affect the price of powder packaging machines?

l Application of powder packaging machine

l Why choose us –Guangdong Smart weigh pack?

l Contact us

There are single and eight station premade pouch powder packaging machines for sale. Single station powder packing machine is suitable for doypack packing with small volume. This system is around 1.1 CBM, it is recommended for limited workshop or semiworks. It can automatically complete picking up bags, coding (optional), filling and sealing. For the packaging with large volume and smart appearance, an eight-station rotary packaging machine can be selected, which is suitable for stand-up bags, zipper bags, special-shaped bags, flat bags, gusset bags, etc.

At the same time, the package provided by Smart Weigh has good compatibility and can be used with other accessories. You can choose measuring cups or linear weighers to integrate with packaging machines according to material characteristics and precision requirements. We provide you with customized service.

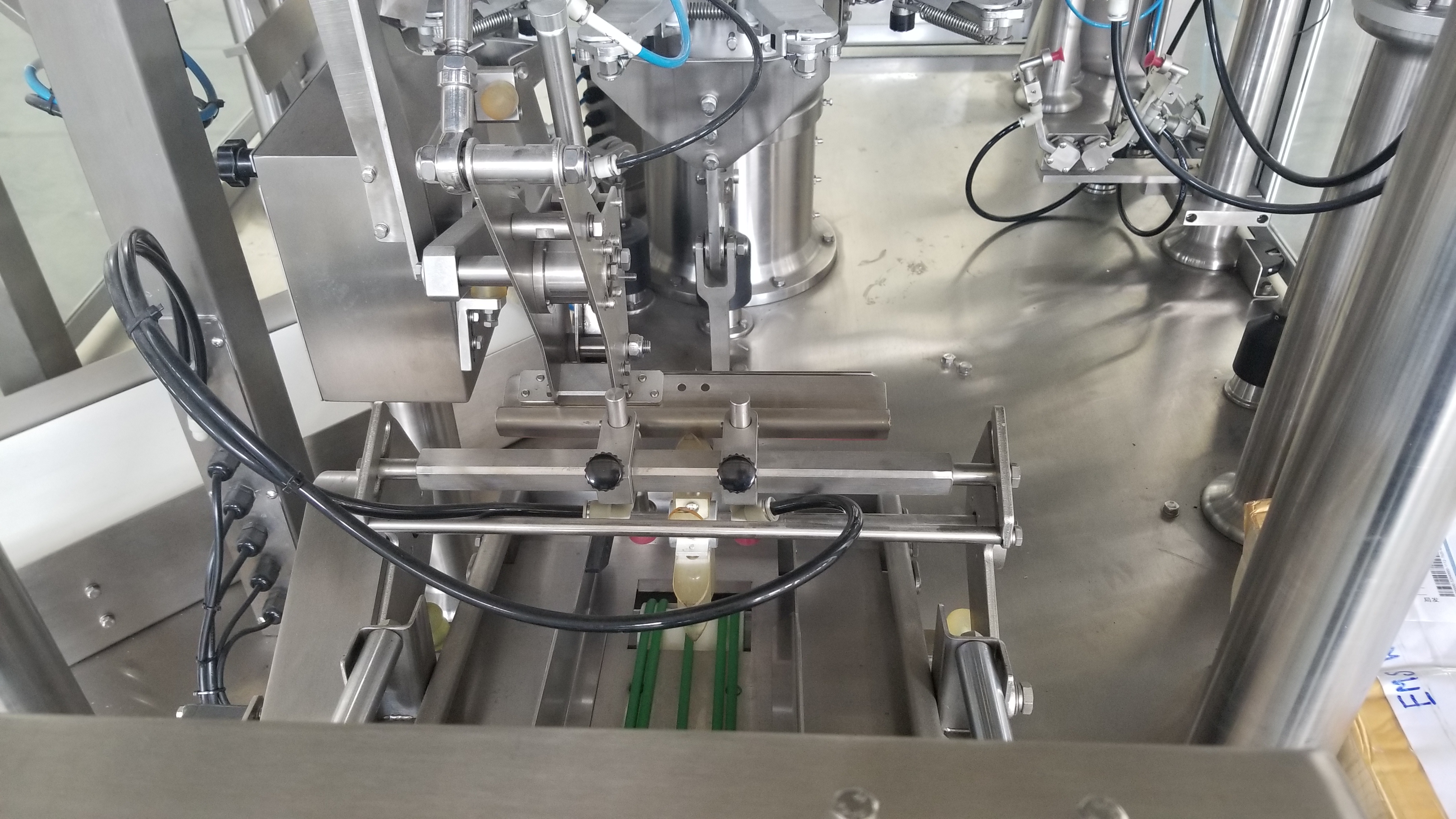

Pre-made bag powder complete packaging system is widely used in packaging bags with beautiful appearance and various styles, and automatically completes the whole process of picking up bags, coding (optional), opening bags, filling, sealing, forming and outputting. The parts that come into contact with food are made of SUS304 material, which is safe and hygienic, and has an IP65 waterproof rating for easy cleaning. The PLC touch screen is easy to use, one worker can operate one machine, the language interface, and the packaging speed can be adjusted as needed. Flexible selection of prefabricated bags of different sizes and styles.

In addition, customers can choose check weigher and metal detectors to reject unqualified weight and metal-containing products.

ü Flexibility to choose the size and style of preformed bags.

ü PLC intelligent color touch screen, multi-language options, easy to operate.

ü Automatic error checking: no pouch, pouch open error, filling error, sealing error.

ü Bags can be recycled, reducing packaging material waste.

ü The width of the bags could be adjusted on touch screen. Press the control-button could adjust the width of all clips.

ü Contact parts is made of SUS304 stainless steel material, safe and hygienic.

ü Heat sealing temperature, language selection, packaging speed can be adjusted.

ü Screws in auger filler are usually used in powder packaging machines to control the packaging weight of materials.

Model | SW-8-200 | SW-R1 |

Suitable bag material | Laminated film | PET/PE |

Bag length | 150 ~ 350mm | 100-300 mm |

Bag width | 130 ~ 250mm | 80-300 mm |

Suitable bag type | Flat, Stand-up, Zipper, Slider-zipper | 3 side seal bag, stand up bag, gusset bag, zipper bag, etc. |

Packing speed | 25 ~ 45 pouches / min | 0-15 bags/min |

Air consumption | 500N liter / min, 6kg/ cm2 | 0.3 m3/min (standard machine) |

Power voltage | 220V/ 380V, 3Phase, 50/ 60Hz, 3.8kw | AC 220V/50 Hz or 60 Hz; 1.2 kW |

are the factors that affect the price of powder packaging machines?

are the factors that affect the price of powder packaging machines?

Powder pouch packing machine price is related to machine material, application technology and replacement of accessories.What are the factors that affect the price of powder packaging machines?

1. The main factors affecting the price of packaging machines are material and performance. Smart Weigh packaging machines are all made of SUS304 stainless steel, with fast packaging speed and high precision.

2. Semi-automatic powder packing machine, the price will be cheaper. Fully automatic powder packaging machine, which can reduce labor costs.

3. The choice of different equipment will also affect the cost of the packaging system. Such as screw feeder, incline conveyor, flat output conveyor, check weigher, metal detector, etc.

Powder packaging machines have been widely used in food and non-food industries. Common powder products include pepper powder, tomato powder, seasoning powder, potato starch, spices, salt, white sugar, medicinal powder, dye powder, washing powder, metal powder, etc. Various bag types and sizes are available: doypack, flat bag, zipper bag, stand-up bag, gusset bag, shaped bag, etc. You can choose different types of packaging machines according to different packaging bags, and we provide customized services according to your actual requirements. Smart Weigh provides you with a fully automatic powder packaging machine with high efficiency, high precision, safety, hygiene and easy maintenance.

Guangdong Smart weigh pack integrates food processing and packaging solutions with more than 1000 systems installed in more than 50 countries. With a unique combination of innovative technologies, extensive project management experience and 24-hour global support, our powder packaging machines are exported overseas. Our products have qualification certificates, undergo strict quality inspection, and have low maintenance costs. We will combine customer needs to provide you with the most cost-effective packaging solutions. The company offers a comprehensive range of weighing and packaging machine products, including noodle weighers, salad weighers, nut blending weighers, legal cannabis weighers, meat weighers, stick shape multihead weighers, vertical packaging machines, premade bag packaging machines, tray sealing machines, bottle filling machines etc.

Finally, our reliable service runs through our cooperation process and provides you with 24-hour online service.

In addition, we accept customized services according to your actual requirements. If you want more details or a free quote, please contact us. We will give you useful advice on powder packaging equipment to boost your business.

The buyers of manual powder filling machine come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

Regarding the attributes and functionality of the manual powder filling machine, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Regarding the attributes and functionality of the manual powder filling machine, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

In essence, a long-standing manual powder filling machine organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. manual powder filling machine QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved