Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Smart Weigh has developed to be a professional manufacturer and reliable supplier of high-quality products. Throughout the whole production process, we strictly implement the ISO quality management system control. Since established, we always adhere to independent innovation, scientific management, and continuous improvement, and provide high-quality services to meet and even exceed customers' requirements. We guarantee our new product multihead weigher will bring you a lot of benefits. We are always standby to receive your inquiry. multihead weigher If you are interested in our new product multihead weigher and others, welcome you to contact us.Smart Weigh is produced in a room in which no dust and bacteria are allowed. Particularly in the assembly of its inner parts which directly contact with the food, no contaminant is permitted.

The sausage packaging machine can be integraded with other components such as a multi-head weigher, platform, output conveyor, and automatic Z-type conveyor thanks to its good compatibility.

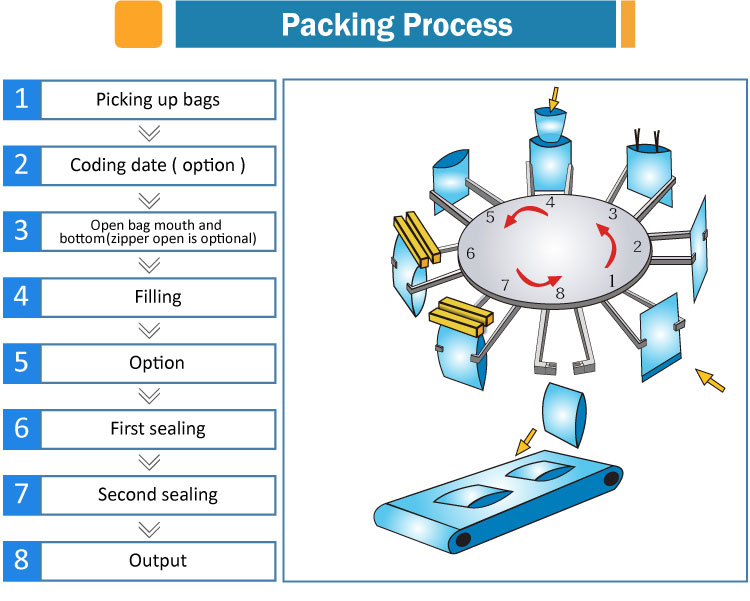

The sausage is first poured into the vibrator feeder by the staff, after which it is automatically poured into the multi-head weighing machine for weighing by the Z conveyor, followed by a series of operations by the premade bag packaging machine including bag picking, bag coding, bag opening, filling, vibrating, sealing, and forming and output, before the product is finally output through the output conveyor. In order to guarantee the quality of the packaging, it can be equipped with a check weigher and a metal detector.

Sausage, bacon, dried meat, beef tendon, and other snacks can all be packaged using pre-made bag packaging machine, which is a common piece of packaging equipment in the food business.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved