With strong R&D strength and production capabilities, Smart Weigh now has become a professional manufacturer and reliable supplier in the industry. All our products including packing machine sugar are manufactured based on the strict quality management system and international standards. packing machine sugar Having devoted a lot to product development and service quality improvement, we have established a high reputation in the markets. We promise to provide every customer throughout the world with prompt and professional service covering the pre-sales, sales, and after-sales services. No matter where you are or what business you are engaged in, we'd love to help you deal with any issue. If you want to know more details about our new product packing machine sugar or our company, feel free to contact us.For years, has dedicated itself to research, development, and production of top-notch packing machine sugar. Our strong technical expertise and extensive management experience have enabled us to form solid partnerships with leading domestic and foreign counterparts. Our packing machine sugar is renowned for its high performance, impeccable quality, energy efficiency, durability, and eco-friendliness. As a result, we have earned a solid reputation in our industry for excellence.

Discover the efficiency and versatility of our doypack packing machines, designed to meet the diverse needs of the packaging industry. Forming the bag from roll of film, accurately dosing the product into the formed pouch, sealing it hermetically to ensure freshness and tamper evidence, then cutting and discharging the finished packs. Our machines provide reliable and high-quality packaging solutions for a wide range of products, from liquids to granules.

Doypack packaging machine types

bg

Rotary doypack packaging machine

They work by rotating a carousel, which allows numerous pouches to be filled and sealed at the same time. Its fast functioning makes it ideal for large-scale production applications where time and efficiency are critical.

Model

| SW-R8-250 | SW-R8-300

|

| Bag Length | 150-350 mm | 200-450 mm |

| Bag Width | 100-250 mm | 150-300 mm |

| Speed | 20-45 packs/min | 15-35 packs/min |

| Pouch Style | Flat pouch, doypack, zipper bag, side gusset pouches and etc. |

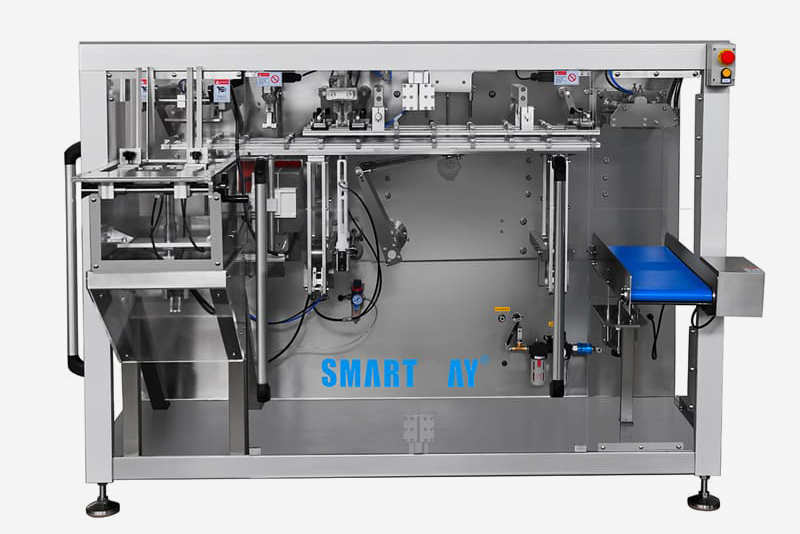

Horizontal doypack packaging machine

Horizontal pouch packing machines are designed for easy operation and maintenance. They are particularly effective for packaging flat or relatively flat products.

| Model | SW-H210 | SW-H280 |

| Pouch Length | 150-350 mm | 150-400 mm |

| Pouch Width | 100-210 mm | 100-280 mm |

| Speed | 25-50 packs/min | 25-45 packs/min |

| Pouch Style | Flat pouch, doypack, zipper bag |

Mini doypack packaging machine

Mini pre made pouches packing machines are the perfect solution for small-scale operations or businesses that require flexibility with limited space. They are ideal for startups or small businesses that need efficient packaging solutions without the large footprint of industrial machines

| Model | SW-1-430 |

| Pouch Length | 100-430 mm

|

| Pouch Width | 80-300 mm |

| Speed | 15 packs/min |

| Pouch Style | Flat pouch, doypack, zipper bag, side gusset pouches and etc. |

Doypack Pouch Packing Machine Features

bg

1. Enhanced Product Presentation

Doypack packing machines are designed to produce attractive, marketable stand-up pouches. These pouches offer considerable space for branding and labeling, making them ideal for products that need to stand out on retail shelves. The aesthetic attractiveness of doypack packaging can improve product visibility and consumer appeal, which is critical for retail success.

2. Versatility and Flexibility

Doypack filling machines are extremely adaptable and can handle a broad variety of materials such as liquids, granules, powders, and solids. This adaptability enables businesses to use a single machine for many items, avoiding the need for different packaging equipment. Furthermore, these machines can accommodate a wide range of bag sizes and kinds, including those with zippers, spouts, and resealable features, providing further customization possibilities to fulfill specific packaging requirements.

3. Efficiency and Cost-Effectiveness

The automated features, such as bag size adjustment and accurate temperature control, eliminate manual involvement and the risk of errors, resulting in lower labor costs and less material waste.

4. Durability and Low Maintenance

Doypack machines are constructed from strong materials and components, ensuring long-term dependability and durability. Stainless steel design and high-quality pneumatic components ensure long-lasting and reliable performance. Many machines include self-diagnostic instruments and replaceable parts, simplifying maintenance and reducing the danger of unexpected malfunctions.

Our doypack packaging machines are ideal for packaging snacks, beverages, pharmaceuticals, and chemical items, catering to a wide range of sectors. Whether you're packing powders, liquids, or granulated items, our equipment perform exceptionally.

Choose from a range of fillers and accessories to customize your doypack machine weighing packing line. Options include auger fillers for powder products, volumetric cup fillers for grains, and piston pumps for liquid products. Additional features such as gas flush and vacuum sealing are available to meet your specific packaging needs.

The buyers of packing machine sugar come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

In essence, a long-standing packing machine sugar organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Smart Weigh Packaging Machinery Co., Ltd. always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

Yes, if asked, we will supply relevant technical details regarding Smart Weigh. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

In China, ordinary working time is 40 hours for employees who work full time. In Smart Weigh Packaging Machinery Co., Ltd., most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Inspection Machine and an unforgettable experience of partnering with us.