Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Always striving toward excellence, Smart Weigh has developed to be a market-driven and customer-oriented enterprise. We focus on strengthening the capabilities of scientific research and completing service businesses. We have set up a customer service department to better provide customers with prompt services including order tracking notice. vacuum packaging machine If you are interested in our new product vacuum packaging machine and others, welcome you to contact us.vacuum packaging machine When it comes to modern machinery, we understand the importance of reliability, stability, and versatility. That's why our products are designed for fast production and processing speeds with low maintenance costs. We prioritize energy-saving and eco-friendly technology to ensure safe and dependable operation. Choose us for optimal performance that won't let you down.

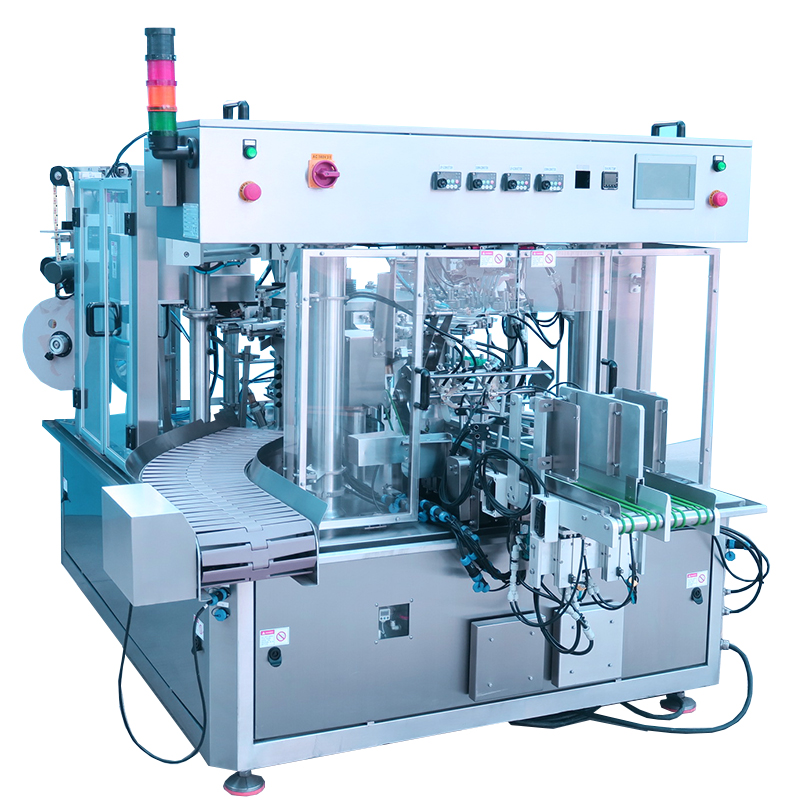

By utilizing continuous motion, rotary premade pouch packaging machine significantly increase production output compared to linear or intermittent motion packers.Innovations in rotary packing technology include the use of servo-driven systems for precise control over speed and positioning, along with automated bag supply and quality control checks. This not only enhances productivity but also reduces material waste and downtime, these machines are widely used in various industries, including food, pharmaceuticals, and non-food items, due to their high-speed capabilities and versatility.

Simplex 8-station Model: These machines fill and seal one pouch at a time, ideal for smaller operations or those requiring lower production volumes.

Duplex 8-station Model: Capable of handling two pre made bags simultaneously, doubling the output compared to Simplex model.

| Model | SW-8-200 | SW-8-300 | SW-Dual-8-200 |

| Speed | 50 packs/min | 40 packs/min | 80-100 packs/min |

| Pouch Style | Premade flat pouch, doypack, stand up pouches, zipper bag, spout pouches | ||

| Pouch Size | Length 130-350 mm Width 100-230 mm | Length 130-500 mm Width 130-300 mm | Length:150-350 mm Width:100-175mm |

| Main Driving Mechanism | lndexing Gear Box | ||

| Bag Gripper Adjustment | Adjustable on Screen | ||

| Power | 380V,3phase,50/60Hz | ||

1. The premade pouch packaging machine adopts mechanical transmission, with stable performance, simple maintenance, longer service life and low failure rate.

2. The machine adopts vacuum bag opening method.

3. Different bag widths can be adjusted within the range.

4. No filling if the bag is not opened, no filling if there is no bag.

5. Install safety doors.

6. The work surface is waterproof.

7. Error information is displayed intuitively.

8. Comply with hygienic standards and easy to clean.

9. Using advanced technology, robust stainless steel material, humanized design, touch screen control system, simple and convenient.

Zipper pouch packing machines are known for their high-speed operation, with some models capable of packing up to 200 pouches per minute. This efficiency is achieved through automated systems that streamline the packaging process from pouch loading to sealing.

Modern rotary packaging machines feature user-friendly interfaces, typically with touch screens, that allow operators to easily control and monitor the packaging process. Maintenance is simplified through easy-to-access components and automated cleaning systems.

These machines can handle a wide variety of products, including liquids, powders, granules, and solid items. They are compatible with different premade pouch types, such as flat pouch, doypack pouches, stand-up pouches, zipper pouches, side gusset pouch and spout pouch, making them suitable for diverse applications.

Nitrogen Flush: Used to preserve product freshness by replacing oxygen in the pouch with nitrogen.

Vacuum Sealing: Provides extended shelf life by removing air from the pouch.

Weigh Fillers: Allow for simultaneous filling of different granule products or higher volumes by multi head weigher or volumetric cup filler, powder products by auger filler, liquid products by piston filler.

Food and Beverage

Rotary packing machines are extensively used in the food industry to pack snacks, coffee, dairy products, and more. The ability to maintain product freshness and quality makes them ideal for these applications.

Pharmaceuticals and Health Products

In the pharmaceutical sector, these machines ensure precise dosing and secure packaging of pills, capsules, and medical supplies, meeting stringent regulatory standards.

Non-Food Items

From pet food to chemicals, premade pouch packaging machines offer reliable packaging solutions for a wide range of non-food products, ensuring safety and efficiency.

Factors to Consider When choosing a rotary premade pouch packing machine, consider the type of product, production volume, and specific packaging requirements. Evaluate the machine's speed, compatibility with different pouch types, and available customizations.

Request a Quote To get personalized recommendations and pricing information, reach out to manufacturers for a quote. Providing details about your product and packaging needs will help in getting an accurate estimate.

Financing Options Explore financing plans offered by manufacturers or third-party providers to manage the investment cost effectively.

Service and Maintenance Packages Regular maintenance is crucial for ensuring long-term performance. Many manufacturers offer service packages that include routine check-ups, spare parts, and technical support.

Technical Support Access to customer support for troubleshooting and maintenance is essential. Look for manufacturers that provide comprehensive support services.

Spare Parts and Upgrades Ensure the availability of genuine spare parts and potential upgrades to keep your machine running smoothly and up-to-date with the latest technology.

Regarding the attributes and functionality of the vacuum packaging machine, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Yes, if asked, we will supply relevant technical details regarding Smart Weigh. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. vacuum packaging machine QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

In China, ordinary working time is 40 hours for employees who work full time. In Smart Weigh Packaging Machinery Co., Ltd., most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Auxiliaries and an unforgettable experience of partnering with us.

The buyers of vacuum packaging machine come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved