Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Over the years, Smart Weigh has been offering customers high-quality products and efficient after-sales services with the aim of bringing unlimited benefits for them. rotary packing machine Today, Smart Weigh ranks the top as a professional and experienced supplier in the industry. We can design, develop, manufacture, and sell different series of products on our own combining the efforts and wisdom of all our staff. Also, we are responsible for offering a wide range of services for customers including technical support and prompt Q&A services. You may discover more about our new product rotary packing machine and our company by directly contacting us. has been focusing on the development and production of rotary packing machine since its establishment, and has accumulated rich experience in manufacturing. With advanced production equipment and mature manufacturing technology, rotary packing machine has excellent performance, stable quality, safe and reliable quality. , enjoying a good reputation in the market.

Model | SW-PL8 |

Single Weight | 100-2500 grams (2 head), 20-1800 grams (4 head) |

Accuracy | +0.1-3g |

Speed | 10-20 bags/min |

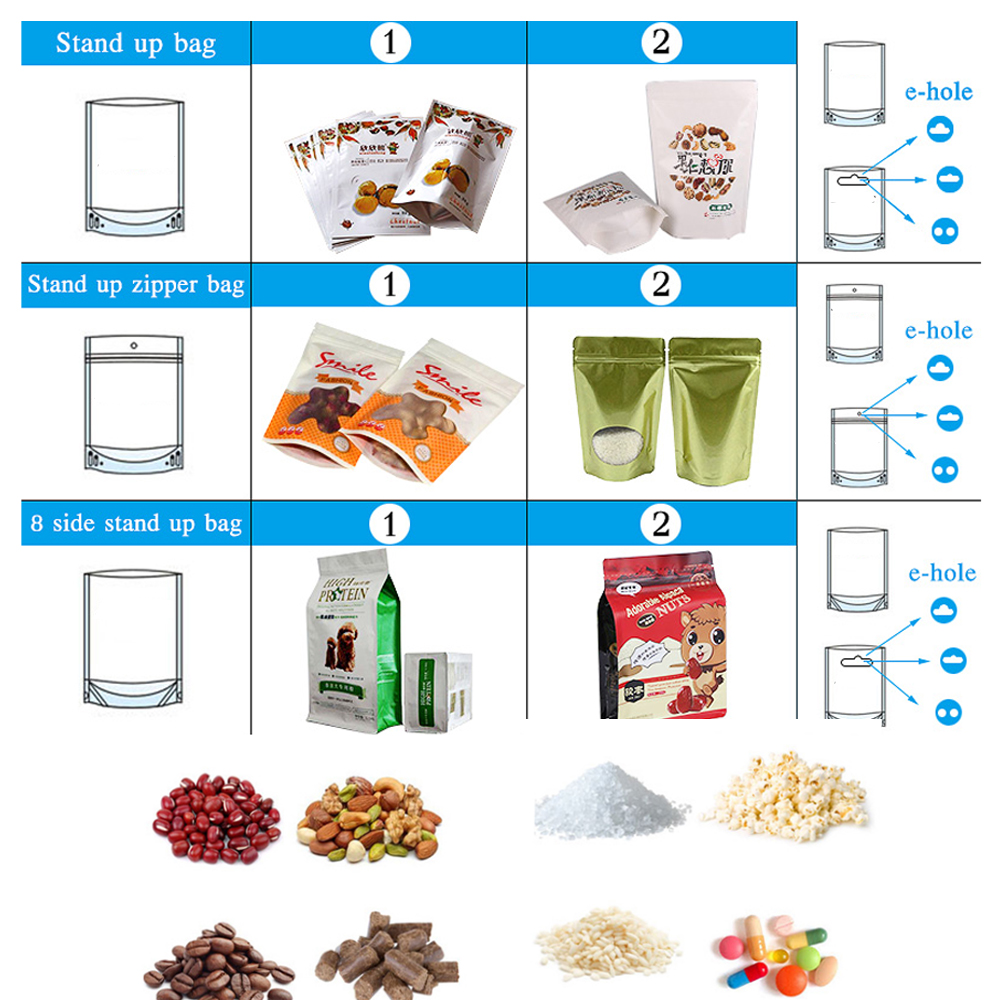

Bag style | Premade bag, doypack |

Bag size | Width 70-150mm; length 100-200 mm |

Bag material | Laminated film or PE film |

Weighing method | Load cell |

Touch screen | 7” touch screen |

Air consumption | 1.5m3/min |

Voltage | 220V/50HZ or 60HZ single phase or 380V/50HZ or 60HZ 3 phase; 6.75KW |

◆ Full automatic from feeding, weighing, filling, sealing to outputting;

◇ Linear weigher modular control system keep production efficiency;

◆ High weighing precision by load cell weighing;

◇ Open door alarm and stop machine running in any condition for safety regulation;

◆ 8 station holding pouches finger can be adjustable, convenient for changing different bag size;

◇ All parts can be taken out without tools.

1. Weighing Equipment: 1/2/4 head linear weigher, 10/14/20 heads multihead weigher, volume cup.

2. Infeed Bucket Conveyor: Z-type infeed bucket conveyor, big bucket elevator, inclined conveyor.

3.Working Platform: 304SS or mild steel frame. (Color can be customized)

4. Packing machine: Vertical packing machine, four side sealing machine, rotary packing machine.

5.Take off Conveyor: 304SS frame with belt or chain plate.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved