Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

After years of solid and rapid development, Smart Weigh has grown into one of the most professional and influential enterprises in China. bottle filling machine Smart Weigh have a group of service professionals who are responsible for answering questions raised by customers through the Internet or phone, tracking the logistics status, and helping customers solve any problem. Whether you'd like to get more info on what, why and how we do, try our new product - Modern bottle filling machine for business, or would like to partner up, we'd love to hear from you.bottle filling machine This product is crafted with the finest materials using state-of-the-art production technology and precise manufacturing processes. Boasting a compact structure, ease of use, and unparalleled quality, it offers unmatched safety and reliability.

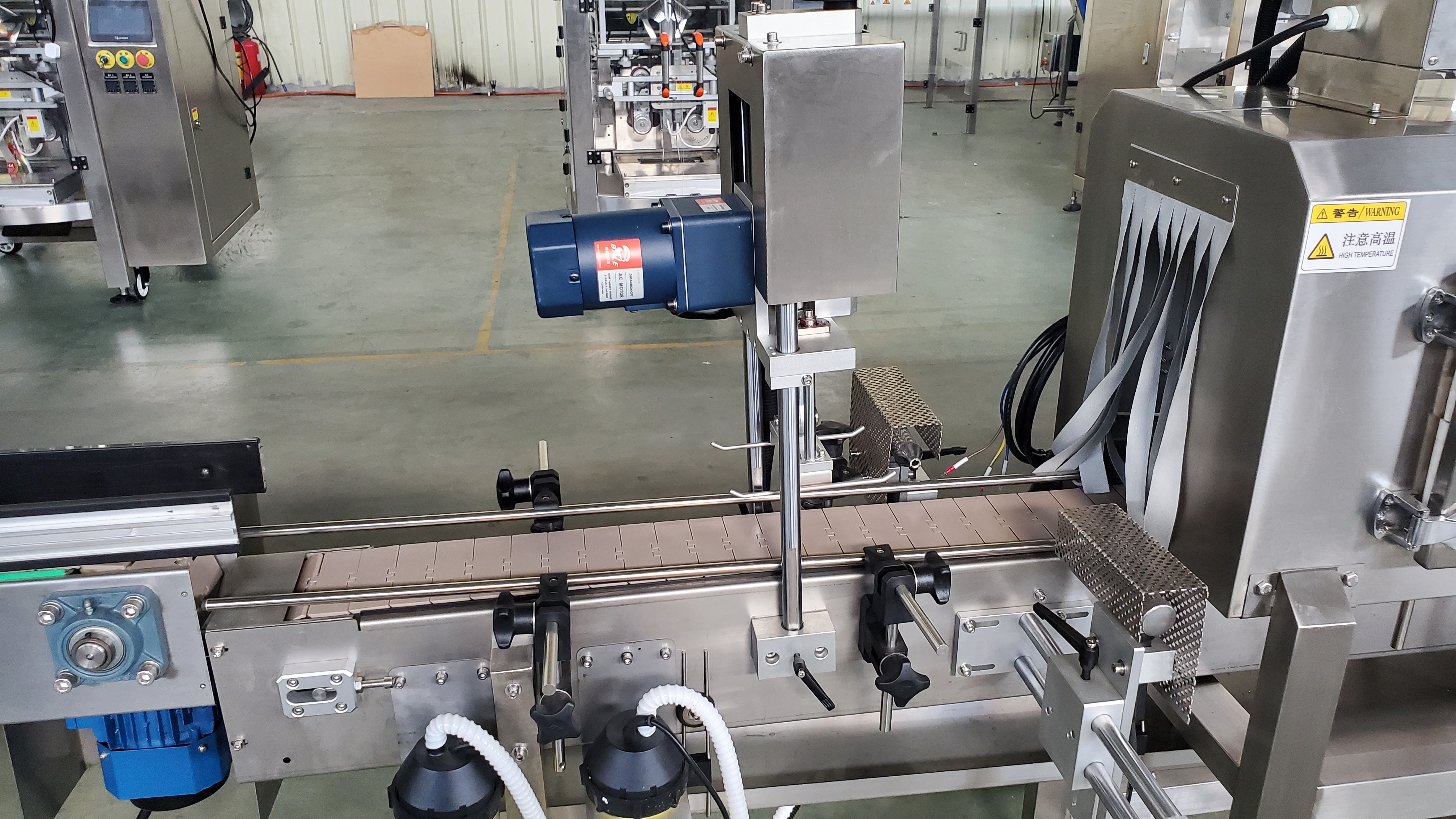

Smart Weigh Pack developed a new pepper curry flavoring spices bottle auto weighing packing line, which speed up to 30 bottles/min ( 30x 60 minutes x 8 hours = 14,400 bottles/day).

| flavoring bottle packing line | |

|---|---|

| Product | pepper curry flavoring spices |

| Target weight | 300/600g/1200G |

| Accuracy | +-15g |

| Package Way | Bottle/jar |

| Speed | 20-30 bottles per minute |

| Elevator | auto lift |

| Working platform | support weigher |

| Double filling machine | auto filling(each time two jars) |

| Washing machine | washing the outside of jar/Rinse the bottle |

| Drying machine | drying by air |

| Bottle feeding machine | auto feeding empty bottle |

| Check weigher | reject over or less target weight product |

| Shrinking machine | auto shrinking |

| Capping mchine | auto feeding caps and auto capping |

| Labeling mchine | auto label |

Yes, if asked, we will supply relevant technical details regarding Smart Weigh. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

Smart Weigh Packaging Machinery Co., Ltd. always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

In China, ordinary working time is 40 hours for employees who work full time. In Smart Weigh Packaging Machinery Co., Ltd., most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Inspection Machine and an unforgettable experience of partnering with us.

Regarding the attributes and functionality of the bottle filling machine, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. bottle filling machine QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

Regarding the attributes and functionality of the bottle filling machine, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved