Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

At Smart Weigh, technology improvement and innovation are our core advantages. Since established, we have been focusing on developing new products, improving product quality, and serving customers. pouch filling and packing machine We promise that we provide every customer with high-quality products including pouch filling and packing machine and comprehensive services. If you want to know more details, we are glad to tell you.The design of Smart Weigh is humanized and reasonable. To make it accommodate to different types of foods, the R&D team creates this product with a thermostat which allows adjusting the dehydrating temperature.

Complete IQF packaging system with multihead weigher,rotary packaging machine,bowl elevator

Dimple design body for option, suitable for meat product

Biggest volume 3.5L hopper for wider applications

IP65 waterproof function, perfect performance under wet and tough working environment.

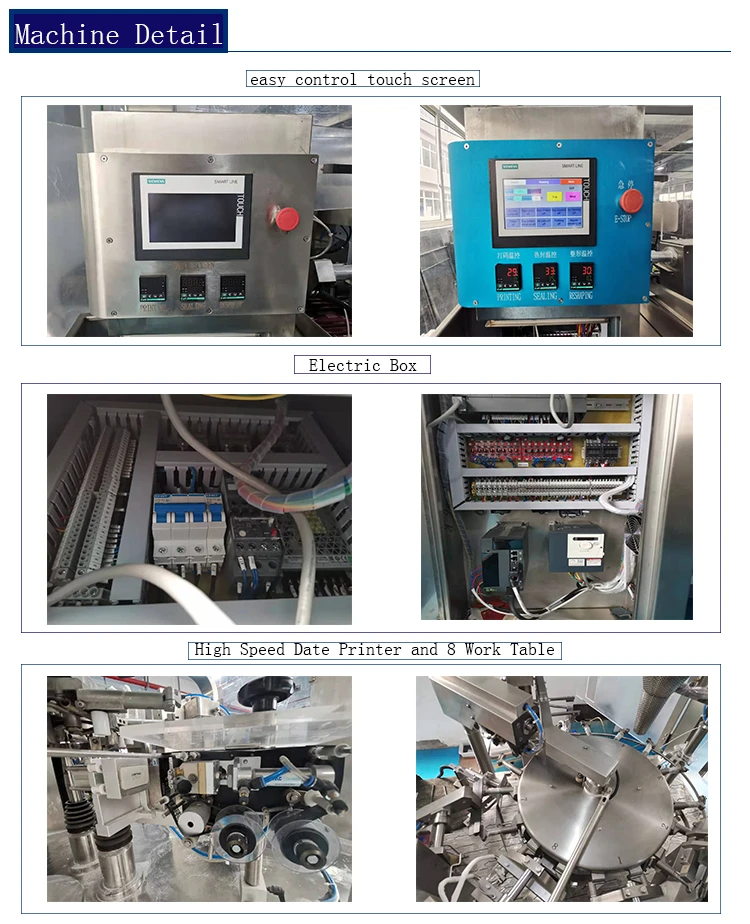

inches touchscreen for enhanced user-friendliness, enhanced calculation software and remote connection capability.

1、It can work with other equipments for continuous or intermittent type weighing and packaging line.

2、The bowl, made of 304 stainless steel material, is easy to disassemble and clean.

3、The stainless steel chain and machine frame makes it strong, durable and not easy to deform.

4、It can feed the material twice through flipping the switch and adjusting the timing sequence.

2、The bowl, made of 304 stainless steel material, is easy to disassemble and clean.

3、The stainless steel chain and machine frame makes it strong, durable and not easy to deform.

4、It can feed the material twice through flipping the switch and adjusting the timing sequence.

High Speed IQF Fish Ball Rotary Packing Machine For Frozen Food premade pouch bag dispensing, opening and closing.

The speed of this machine is adjusted by frequency conversion with the range, and the actual speed depends on type of products and pouch.

Strict mechanical safety standards to ensure stable operation of machinery and increase packaging speed.

Improve the solution, reduce the cost for you.

Heavy parts are used to improve the durability of machinery.

The simple design of the touch screen control system facilitates the use of operators, and is simple and easy to use.

Automatic checking system can check bag situation, filling and sealing situation

Versatile in design, easy to link up with other down stream packaging equipment such as liquid filler, multi-heads weigher, metal detector, check weigher, case sealer etc.

The product and pouch contact parts are adopted stainless steel and other advanced material to guarantee the hygiene of products

The production line meets the requirements of food hygiene and is convenient to clean.

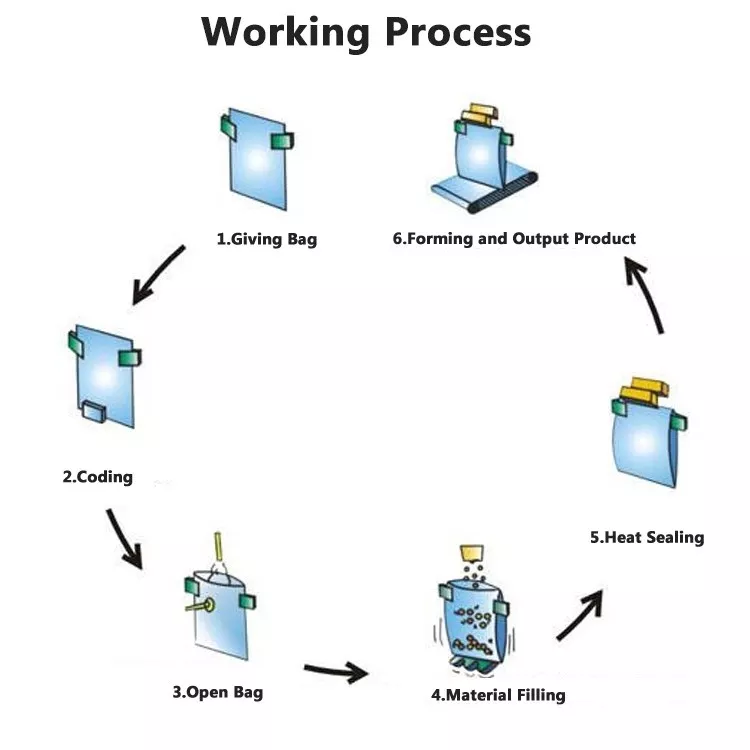

Automatic control of a series of processes from loading, filling, sealing, and finished products.

Block material: ,fish, frozenfood,candy, cereal, chocolate, biscuit, peanut, etc.

Granular type: crystal monosodium glutamate, granular drug, capsule, seeds, chemicals, sugar, chicken essence, melon seeds, nut, pesticide, fertilizer,etc.

All type of heat sealable performed side seal bags,block bottom bags,zip-lock recloseable bags,stand-up pouch with or without spout,paper bags etc.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. pouch filling and packing machine QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

In essence, a long-standing pouch filling and packing machine organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

In China, ordinary working time is 40 hours for employees who work full time. In Smart Weigh Packaging Machinery Co., Ltd., most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Auxiliaries and an unforgettable experience of partnering with us.

The buyers of pouch filling and packing machine come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

Regarding the attributes and functionality of the pouch filling and packing machine, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved