Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Guided by scientific and technological innovation, Smart Weigh always keeps outward-oriented and sticks to the positive development on the basis of technological innovation. automated packing systems We have professional employees who have years of experience in the industry. It is them that provides high-quality services for customers all over the world. If you have any questions about our new product automated packing systems or want to know more about our company, feel free to contact us. Our professionals would love to help you at any time.With its scientific and well-planned design, coupled with a simple yet compact structure, safety and effective airtightness, this food container is the perfect storage solution. automated packing systems Keep your food fresh and delicious for an extended period without worrying about spoilage or contamination.

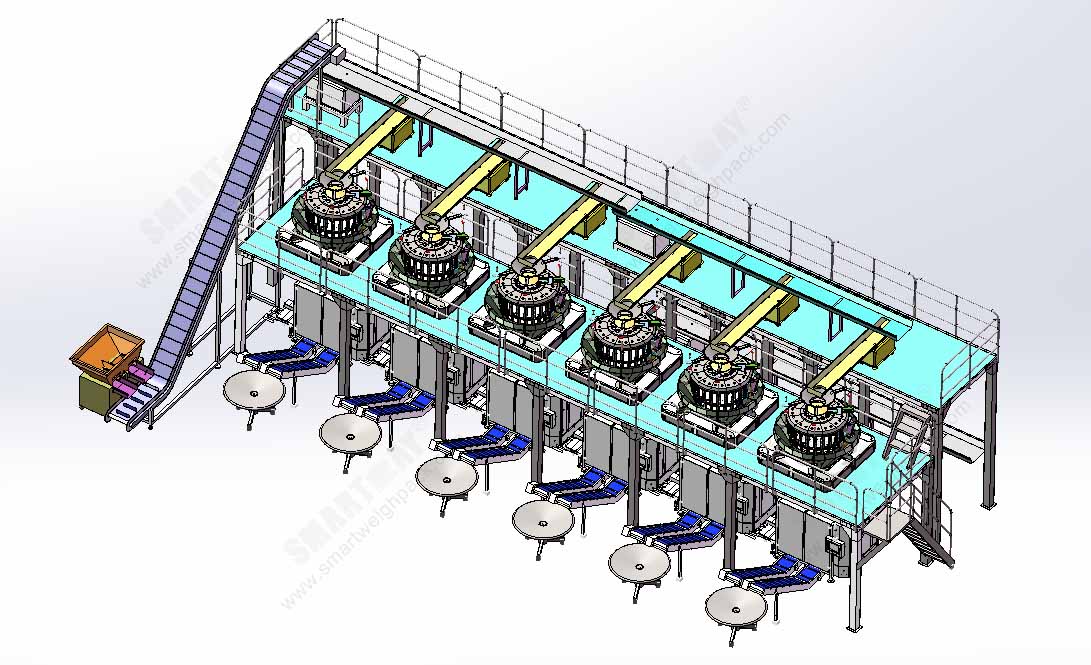

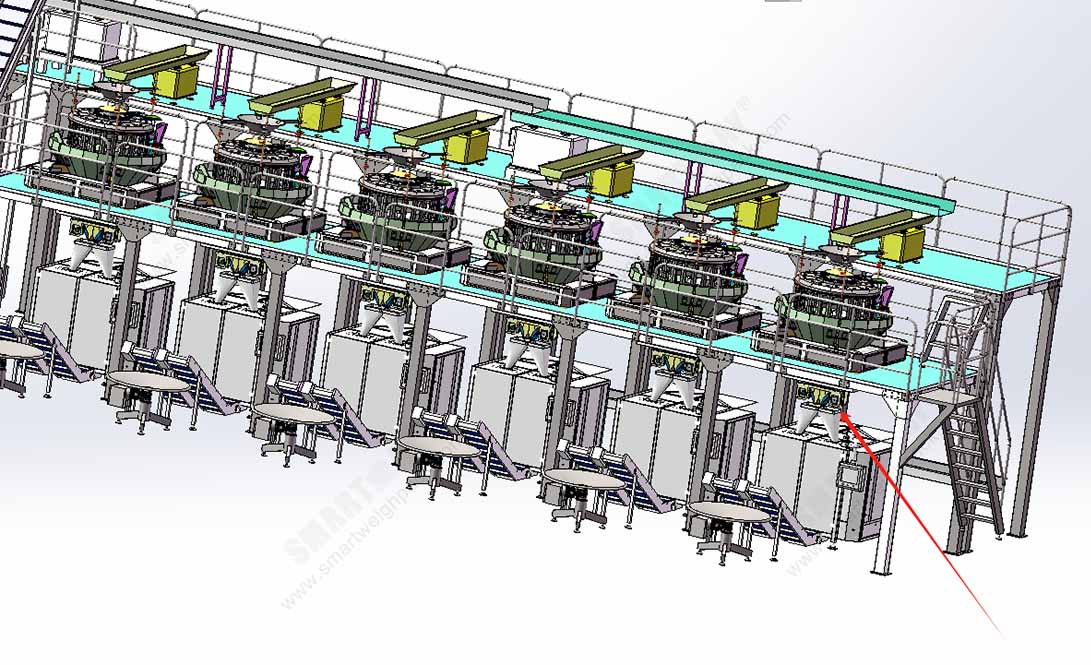

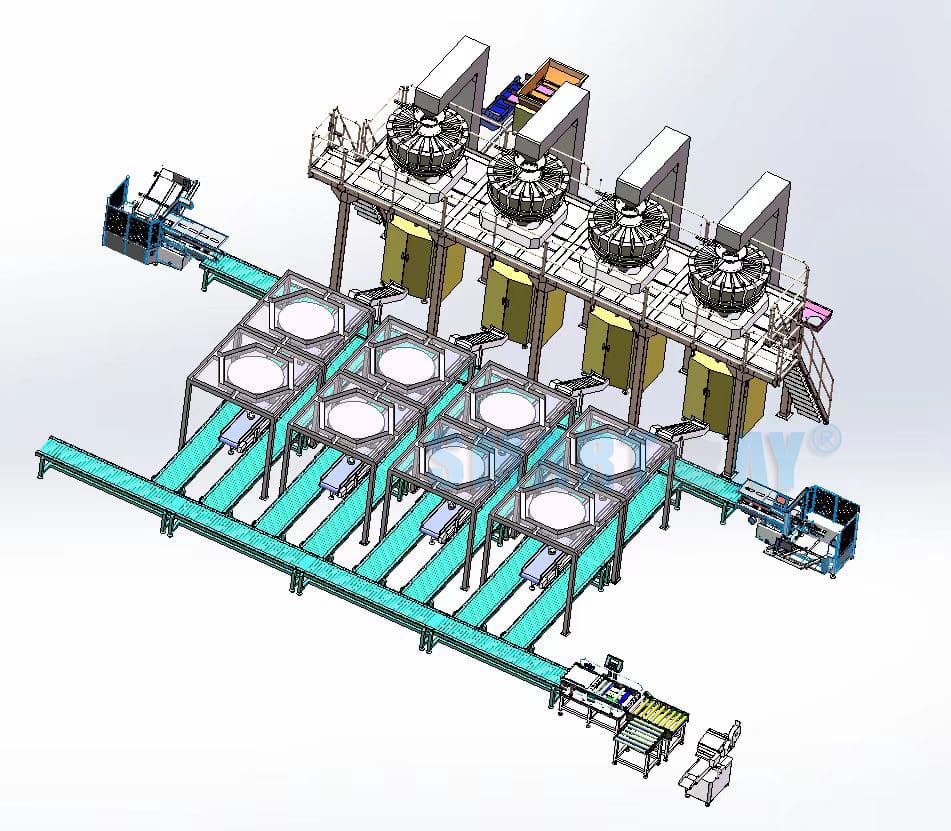

Discover the ultimate solution for snack manufacturers: the ultra high-speed chips packing machine line. Designed to deliver unmatched efficiency and precision, this advanced system integrates cutting-edge 24-head multihead weighers and high-speed vertical packing machines, tailored for lightweight snacks.

Weight Range: 5-50 grams

Speed: 200 packs/min per machine; total system output of 1200 packs/min

This system empowers snack manufacturers to scale production while optimizing space and minimizing costs.

Dual-Bag Former Design: Each vertical packing machine produces two bags per cycle, doubling output without doubling the footprint.

Space and Cost Efficiency: One 24-head weigher serves two bag formers, reducing the need for extra equipment and operational costs.

Specialized Feeding System: Engineered for lightweight snacks, the feeding system minimizes product breakage and maximizes accuracy.

24-Head Multihead Weigher:

● Precision weighing for small weight ranges, ensuring consistent pack accuracy.

● Designed for ultra-fast speeds while minimizing product waste.

● Twin filling design save space and machine cost.

High-Speed Vertical Packing Machines:

● Advanced systems with 2 bag formers: form, seal, and cut two bags per cycle, speed up 200 packs/min per machine.

● Versatility to accommodate various bag styles, including pillow and linked pillow bags.

Compact and Modular Design:

● Streamlined for seamless integration into existing production spaces.

● Modular setup allows customization to fit diverse operational needs.

Perfect for packing a variety of snacks, including:

● Potato chips

● Popcorn

● Tortilla chips

● Crackers

● Other lightweight food products

Main Machines | 24 head multihead weigher Twin formers vertical packing machine Feeding system: incline conveyor with fastback feeder Output conveyor Rotary collect table |

|---|---|

| Weight | 5-50 grams |

| Speed | 200 packs/min/unit |

| Bag Style | Pillow bags, pillow linked bags |

| Bag Size | Width 60-200mm, length 80-250mm |

| Bag Material | Laminated film |

| Voltage | 220V, 50/60Hz |

| Control System | Multihead weigher: modular control; Vertical packing machine: PLC+servo motor |

| Touch Screen | Weigher: 10" touch screen; vffs: 7" touch screen |

Tailored Configurations: Adjust layout, and weighing precision to meet production demands.

Optional Add-Ons: Integrate conveyors, checkweighers, cartoning machine and palletizing systems to create a fully automated production line.

Take your snack production to the next level!

Contact us today to schedule a demo, request a quote, or explore customized solutions tailored to your needs.

Ultra High-Speed Chips Packing Machine Line: Precision, efficiency, and innovation in one compact system.

The application of the QC process is crucial for the quality of the final product, and every organization needs a strong QC department. automated packing systems QC department is committed to continual quality improvement and focuses on ISO Standards and quality assurance procedures. In these circumstances, the procedure may go more easily, effectively, and precisely. Our excellent certification ratio is a result of their dedication.

In essence, a long-standing automated packing systems organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

The buyers of automated packing systems come from many businesses and nations around the world. Before they begin working with the manufacturers, some of them may reside thousands of miles away from China and have no knowledge of the Chinese market.

Smart Weigh Packaging Machinery Co., Ltd. always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

In China, ordinary working time is 40 hours for employees who work full time. In Smart Weigh Packaging Machinery Co., Ltd., most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Packing Line and an unforgettable experience of partnering with us.

Yes, if asked, we will supply relevant technical details regarding Smart Weigh. Basic facts about the products, such as their primary materials, specs, forms, and primary functions, are readily available on our official website.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved